Subjects:

- Assembling the MegaSquirt II ECU

- JimStim Simulator

- Tuner Studio

- Settings

Assembling the MegaSquirt II ECU:

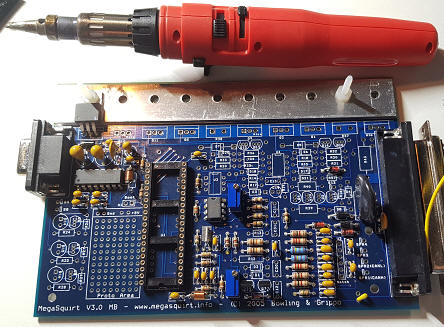

The MegaSquirt is supplied as a kit. The composition of the MegaSquirt depends on the motor configuration and the sensors and actuators used. Not in all cases the components can withstand large currents. When choosing the ignition driver, the type of ignition coil used must also be taken into account. A choice must already be made between three different options for assembling the MegaSquirt. In many cases, multiple circuits can be mounted, but the correct circuit is activated by means of jumpers.

The image shows an overview of the supplied parts. The simulator can be seen at the top left, with which the input and output signals of the MegaSquirt can be created and measured after the assembly process. In the bottom center on the left the MegaSquirt circuit board and on the right a bag with large connection components. The daughterboard, which also makes it a MegaSquirt 2 version, can be seen at the top center. This daughter board is later slid into the mounted processor socket. Between the clearly visible parts are fifty bags with separate components. Inside each pouch are several electrical components, such as resistors, transistors, diodes, opamps, voltage stabilizers, LEDs, an opto-coupler, and a number of other ICs.

JimStim Simulator:

The simulator used is suitable for setting up the MegaSquirt before mounting it on a motorcycle. The simulator has a number of hardware circuits with which sensor signals can be created. Turning the potentiometers results in changing sensor values. On the computer screen, the meters in the TunerStudio program will display the values (Appendix 29). The sensors that can be simulated are as follows:

- Intake air temperature;

- Coolant temperature;

- throttle position;

- Lambda value;

- (Reserve);

- crankshaft speed;

- Crankshaft speed (fine adjustment).

In addition to the sensor values, the engine management adjustments can also be checked. Adjusting one sensor value can have consequences for the control of one or more actuators. At the connections, which serve as breakout box, it is possible to measure the signals using a multimeter or oscilloscope.

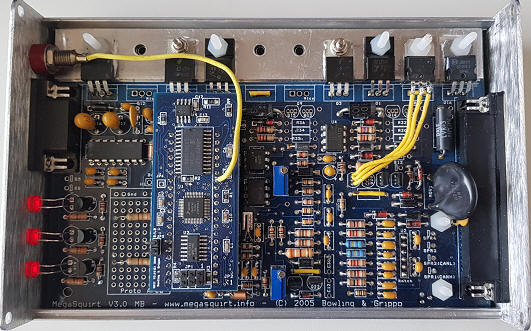

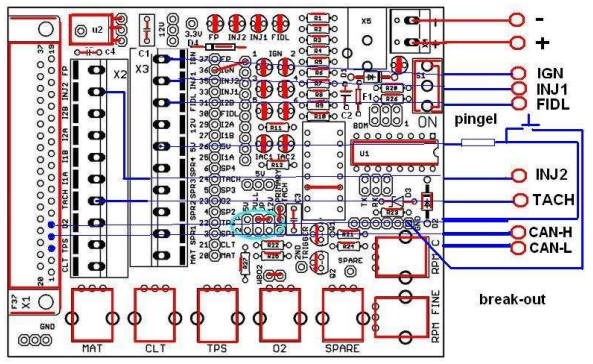

The image shows JimStim's assembled simulator without controllers and jumpers installed. On the left side you can see the plug connection where a flat cable makes the connection between the MegaSquirt and the simulator possible. After the assembly process is complete, the simulator is replaced by the plug on the motor that connects all sensors and actuators.

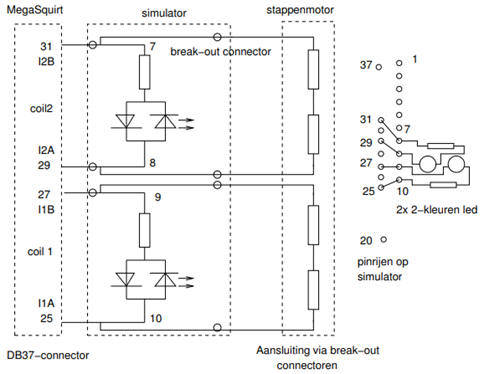

There are a number of dip switches on the simulator. This will set the crankshaft signal correctly. Appendix 17 provides a schematic overview. For example, it is possible to choose between a 36-1 or a 60-2 crankshaft reference wheel, between a 5 volt or 12 volt signal, and whether the crankshaft position sensor provides an AC or DC voltage signal. Naturally, the settings are chosen that correspond to the parts as they will be mounted on the engine. The simulator is equipped with a number of LEDs. These LEDs illuminate or flash when controlling the following electrical components:

- Fuel pump;

- Injector control 1;

- Injector control 2;

- Ignition control 1;

- Ignition control 2;

- PWM signal from the idle control valve (if equipped);

- Stepper motor control (if present).

The JimStim simulator is mounted on a clear Plexiglas panel. Measuring connections have been made in the Plexiglas. The connection between the simulator and the measurement connections must be made by means of soldering wires.

Tuner Studio:

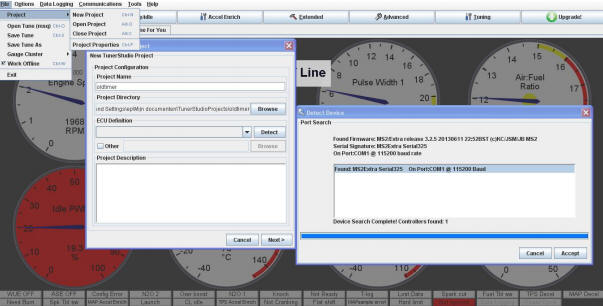

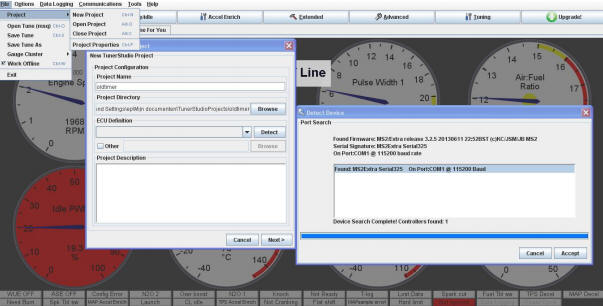

The MegaSquirt II ECU is connected to a desktop PC or laptop by means of the software program “TunerStudio”. Settings can be loaded into the MegaSquirt through this program. The image below shows the screen where the MegaSquirt is connected to the PC via a COM port.

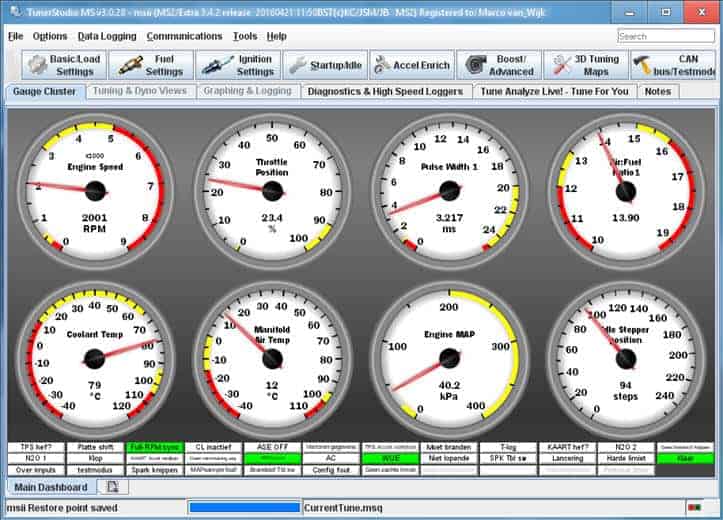

The image below shows the TunerStudio meters. While operating the potentiometers on the simulator, or while the motor is running, the meters in this screen indicate the sensor values and actuator controls.

- Engine speed: Crankshaft speed

- Throttle Position: Throttle Position, Opening Angle

- Pulse Width 1: Injector Opening Time

- Air:Fuel Ratio 1: Actual Air/Fuel Ratio

- Coolant Temp: Coolant Temperature

- Manifold Air Temp: Intake Air Temperature

- Engine MAP: Intake manifold vacuum

- Idle Stepper Position: Stepper motor position, number of steps

Engine settings in TunerStudio:

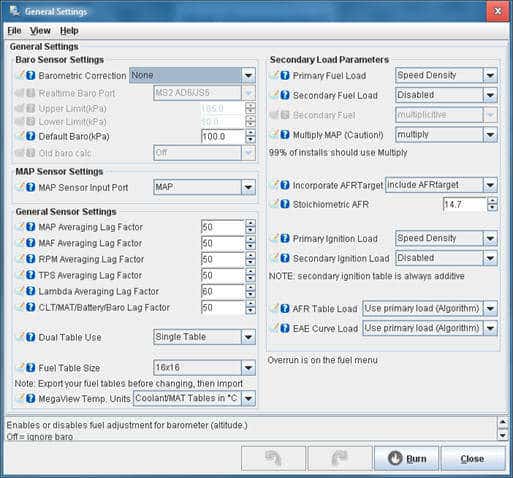

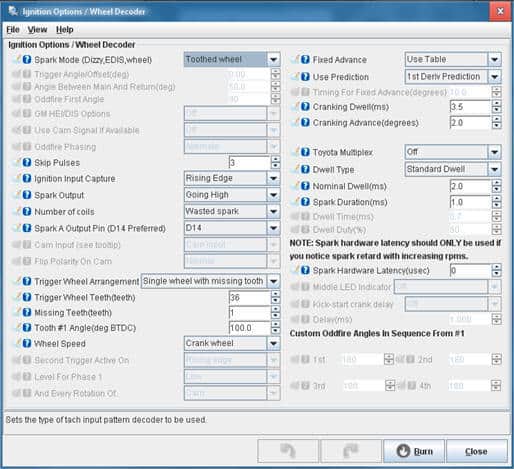

The motor properties are filled in in the TunerStudio program. The images below show the screens used to make the settings.

Next: Settings