Engine Torque:

The engine torque is the force with which the engine’s crankshaft rotates. The torque is generated by the combination of combustion force on the piston and the distance of the crank radius. The force on the piston depends on factors such as the filling ratio (air quantity) and fuel quantity and varies because the angle of force transmission on the crank pin constantly changes. We can derive the average piston pressure from the indicator diagram or pv-diagram.

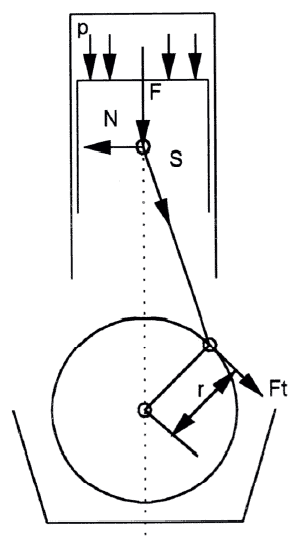

In the following line drawing, we see the piston being pushed down by the combustion force (p). This combustion pressure creates force F, the piston force. The piston force is transferred via the connecting rod (S) to the crank pin (r). This creates the so-called tangential force (Ft).

The torque is calculated with the formula Ft x r (the tangential force multiplied by the crank radius) and is expressed in Nm (Newtonmeter).

Legend:

p = pressure on the piston.

F = the force on the piston

N = Guideway force

S = Force on the connecting rod

r = Crank radius

Ft = Tangential force a0

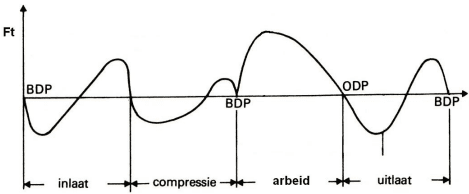

Due to the fluctuating combustion pressure and the rotation of the crank-connecting rod mechanism, the tangential force is also not a constant magnitude. We, therefore, use an average tangential force. a0

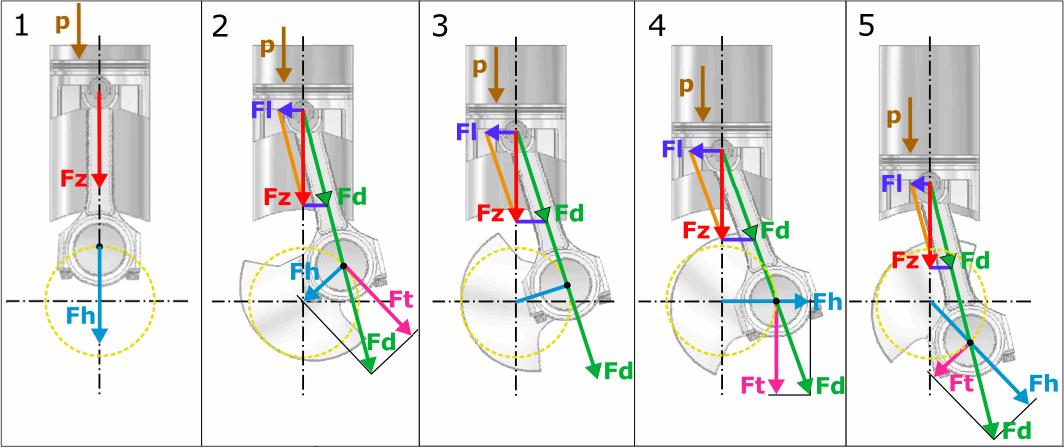

We can determine the tangential force when we resolve the piston force (see the image below and the page “resolving piston force“).

The engine torque solely depends on the force on the piston because all other magnitudes, such as piston diameter and crank radius, are fixed engine data. The force on the piston (Fz) is caused by the combustion pressure (p) and depends on the engine’s filling ratio (with stoichiometric mixture ratio). It is mainly the throttling in the intake manifold that determines the engine’s filling ratio.

The greatest throttling is caused by the position of the throttle valve. The throttle position thus has the greatest influence on engine torque: we indeed influence the engine performance by changing the throttle position. a0In an experimental setup, we measure the maximum delivered torque with a fully opened throttle.

The torque is not the same at various RPMs and with a fully opened throttle. Due to changing gas speeds and fixed valve opening angles, the torque will only be optimal at a certain RPM.

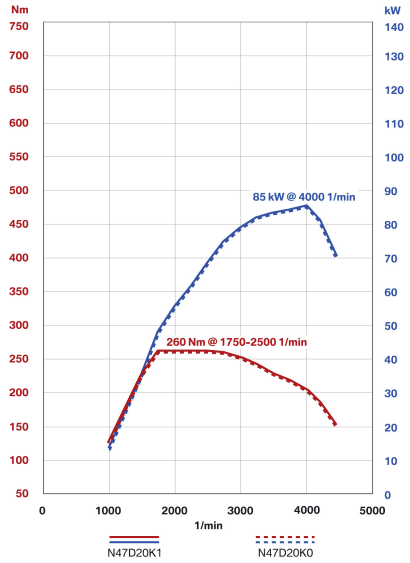

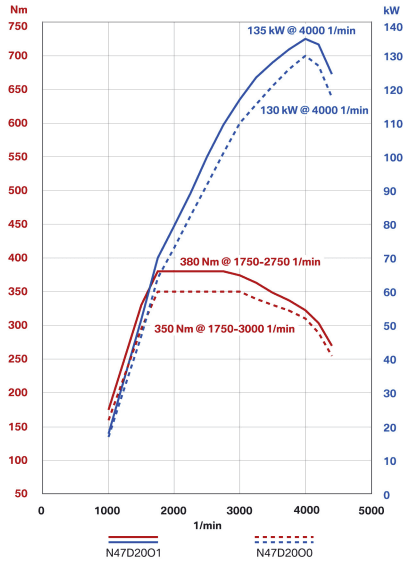

In the images below, we see the power and torque diagrams of two types of diesel engines used in a BMW 3-series (E9x). In both engines, the torque is achieved at approximately 1800 RPM, but it is clearly higher in the 320d than in the 316d. Both engines have a displacement of 2.0 liters. The higher torque is, among other things, enabled by forced induction, valves in the intake manifold, and the engine management system mapping, which in addition to determining the torque, is crucial for consumption and exhaust emissions.

Engine Power:

In the factory specifications, in addition to engine torque, engine power is also mentioned. Engine power is a multiplication of engine torque with engine RPM. Power represents how many times the torque can be delivered per second. a0 The official formula is:

where P is the power in Nm/s or Watt, M is the torque in Nm, and c9 (omega) is the angular velocity. For torque, the letter T is also used instead of M.

Since the angular velocity (c9) is equal to 2 * 3c0 * n, where n is the number of rotations per second, we can change the formula to:

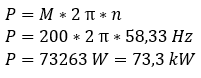

As an example, we take an atmospheric four-cylinder 2.0-liter FSI engine with four valves per cylinder from VAG (engine code: AXW). Of course, we can read the torque and power from the graph, but in this paragraph, we calculate the power based on the torque.

Data:

- engine torque: 200 Nm;

- RPM: 3500 RPM = 58.33 revs/sec.

Required: the delivered power at the given RPM.

The delivered torque and power at 3500 RPM is 200Nm and 73.3 kW.

Measuring Torque and Power:

Torque is directly responsible for the car’s pulling force. Torque is multiplied by the gear ratio (i) of the transmission and final drive, and divided by the loaded radius (rb) of the driven wheels (see the page calculating gear ratios).

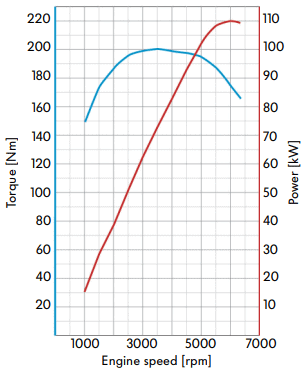

Engine torque is measured by braking the engine with a fully opened throttle at various RPMs. By braking the engine, the chosen RPM is kept constant. The braking force of the engine, multiplied by the radius of the measurement object on which the force acts, then gives the engine torque.

For power measurement, an eddy-current brake can be used. The measurement takes place directly on the crankshaft. Electromagnets induce eddy currents in a metal disc, with the braking force measured by the deflection of a torsion element. In a power measurement of an engine on an eddy-current brake, the RPM and torque are the measured quantities. Power is then determined through calculation (see the previous section).

The power of a vehicle can also be measured directly at the wheels. However, losses up to 70% should be accounted for. These losses occur in the transmission. The axle power (the power measured at the wheels, power test bench), is also called the DIN-hp. The power measured at the flywheel is the so-called SAE-hp. SAE stands for Society of Automotive Engineers. The value of SAE will therefore always be higher than that of DIN.

The metal rollers of the test bench are connected to a braking mechanism, mostly an eddy current brake. The force with which the rollers are braked, together with the RPM of both the wheels and the crankshaft, measures the delivered torque and calculates the power. The measurement usually occurs in the highest or one of the highest gears with the throttle fully engaged. A loss of 15 up to 30% is not uncommon for two-wheel-driven vehicles. The computer of the power test bench compensates for this loss by measuring how much power it takes to drive the power test bench vehicle. During this measurement, the vehicle rolls out with the clutch engaged.

Constructors or tuners try to keep the torque curve as flat as possible, so that the engine torque remains the same over as many RPMs as possible. Especially engines with forced induction (turbo / supercharger) that significantly increase torque, can be tuned to be as flat as possible in this manner. Also, by applying techniques to increase filling ratio, such as multi-valve engines, variable valve timing or a variable intake manifold the torque area can be kept as flat as possible.

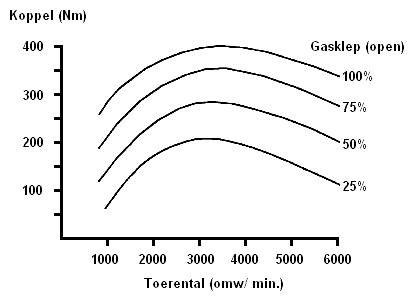

If we were to measure the torque at different throttle positions, we would get a pattern as in the next image. However, such a measurement is rarely performed.

Horsepower (hp) and Kilowatt (kW):

To express a vehicle’s work rate, the units “horsepower” and “kilowatt” are used. Power depends on the torque per second. The definition of horsepower dates back to when transportation was still with horse and carriage. If a mass of 75 kilograms is lifted one meter in one second, 1 hp of power is delivered. 1 hp is thus 75 kg * 1 meter / 1 second.

Looking at power from the unit Watt, 1 Watt is a multiplication of 1 Newton * 1 meter per second. We abbreviate this as [1 Nm / sec].

The horsepower used in the Netherlands (pk) is exactly the same as the German Pferdest 3a4rkte (PS) and the French Chaval-Vapeur (CH).

1 hp = 0.7355 kW

1 kW = 1.3596 hp

The English / American horsepower (hp) is larger.

1 hp = 0.7457 kW

1 kW = 1.3410 hp

When converting horsepower to Watts, we multiply the mass by the gravitational acceleration: 1 HP = 75 kg/sec * 9.81 m/s^2 = 7355 W = 0.7355 kW.

To convert the power of an engine with 150 hp, we multiply the number of kg/sec by the number of hp. This results in: (150 * 75) * 9.81 = 110.4 kW.

We can also convert power in Watts to horsepower. We do this as follows: a0 1 / 0.7355 (W) = 1.36 hp. An engine with a power of 92 kW delivers, according to the calculation: (1 * 92) / 0.736 = 125 hp.

Related pages: