Subjects:

- General

- Origin of soot particles

- How a diesel particulate filter works

- Self-generating diesel particulate filter

- Half open soot filter

- Exhaust gases from a diesel engine

General:

A particulate filter is used on diesel engines. The purpose of a particulate filter is to allow the exhaust gases to pass through and to stop the soot particles. Nowadays, every diesel engine of a new car is equipped with a particulate filter to meet the strict environmental requirements. In some large cities it is already illegal for 'dirty' diesel cars without a particulate filter and petrol cars without a catalytic converter.

Origin of soot particles:

Soot particles are always formed during the combustion process of a diesel engine. Soot is a sign of incomplete combustion. Soot particles are small carbon spheres with a core of pure carbon, with a diameter of about 0,05 micromillimeters. Certain harmful substances, including hydrocarbons, sulfur and metal oxides, adhere to the core of this carbon. Some hydrocarbons can be harmful to health.

The formation and quantity of the soot particles depend in particular on use, air supply, injection and combustion of the engine. In particular, when there is a shortage of oxygen, the soot emissions increase, because the mixture is too rich and the combustion is therefore incomplete. Chip tuning can also be a cause of excessive soot emissions.

The dimensions of the soot particles are virtually the same for indirect injection diesel engines with swirl chamber, direct injection, common rail and unit injector engines.

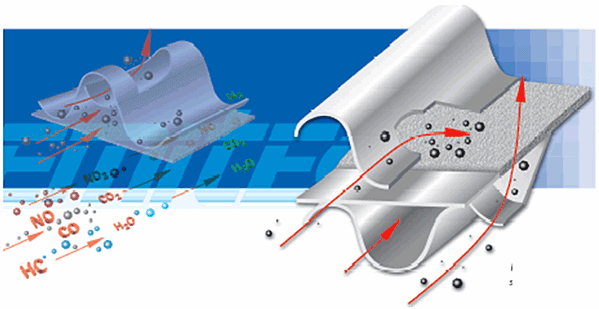

Operation of a particulate filter:

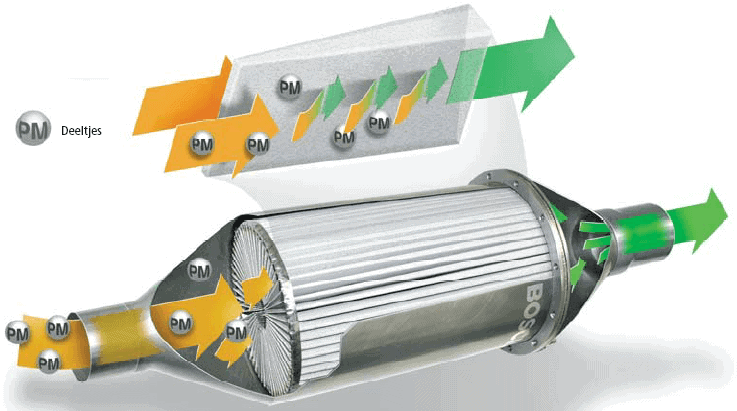

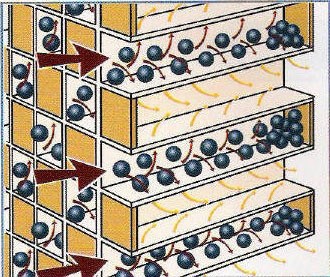

The particulate filter consists of a honeycomb ceramic body made of silicon carbide, which is housed in a metal housing. The ceramic body consists of many parallel, microscopic passages, which are closed alternately on one side.

When the exhaust gases pass through the particulate filter, the particles are retained in the entry channels, while the other gaseous components of the exhaust gas pass through the porous walls of the filter.

Self-generating diesel particulate filter:

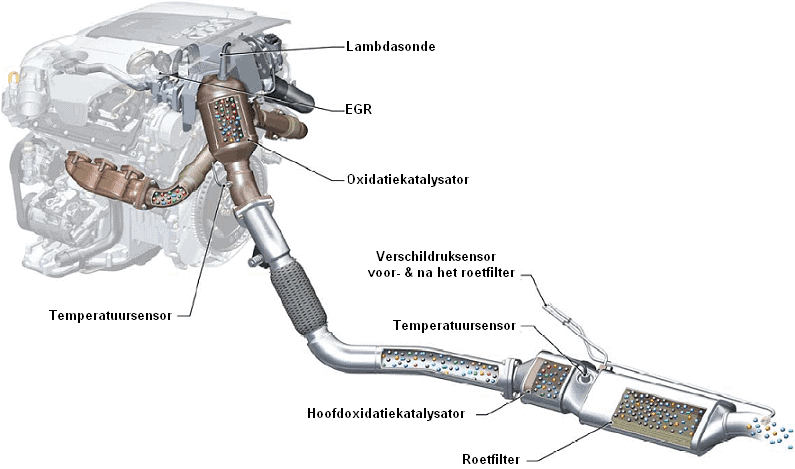

A self-generating particulate filter blocks about 90% of all soot emitted by the engine. Because after a while many soot particles remain in the self-generating soot filter, it would become clogged without measures. To prevent this, the filter must be regenerated regularly (every 200-1000km). This is called the “regeneration process”. This means that the accumulated soot particles are burned. During combustion, the particles are converted into the harmless substances carbon dioxide and water. The combustion temperature of the soot particles in soot filters without a catalytic coating is at least 600ºC, but the exhaust gases are often not hot enough for that. The following methods can be used to burn the soot particles:

- Diesel particulate filter with a catalytic coating:

This type of soot filter has a catalytic coating, which makes it possible to combine the soot particles at a temperature of 250ºC. However, the particulate filter must be placed as close to the engine as possible, because otherwise a lot of heat is lost. This method of regeneration is used, for example, in semi-open and continuously regenerating soot filters. - Using an oxidation catalytic converter: With an oxidation catalytic converter, the nitrogen oxides in the exhaust gases are partly converted into nitrogen dioxide. This nitrogen dioxide is very reactive, so that the soot ignites much more easily and therefore at a lower temperature. The oxidation catalytic converter is therefore always placed in front of the particulate filter, usually even directly after the exhaust manifold. Sometimes even 2 of these catalysts are installed. (see the picture)

- External heating: By placing a glow plug or fuel injector in the exhaust, it is possible to reach the necessary temperature to ignite the soot particles. This is controlled by the engine control unit. This registers the values coming from the differential pressure sensors that measure before and after the filter that the particulate filter is starting to get full.

- Additional Fuel Injection: Adding fuel to the injectors on the exhaust stroke raises the exhaust gas temperature, allowing regeneration to be accomplished.

Semi-open particulate filter:

Semi-open particulate filters are designed for cars that are not fitted with a particulate filter as standard. This type of particulate filter is therefore retrofitted. The number of semi-open particulate filters is decreasing, because all new cars are now fitted with a particulate filter as standard.

Semi-open particulate filters have an open structure that allows the exhaust gases to flow through the filter unhindered. Some of the soot particles will stick to the walls. The filter has a catalytic coating on the inside, which makes it possible to regenerate (burn off) the soot particles at low temperatures. Regeneration takes place continuously at a high temperature. The chance that the filter will become clogged is small, provided the filter is warmed up every now and then. The major disadvantage is that under optimal conditions emissions can only be reduced by up to 60% and emissions under less-than-optimal conditions, which is often the case during normal use, can only be reduced by 30%.

Exhaust gases from a diesel engine:

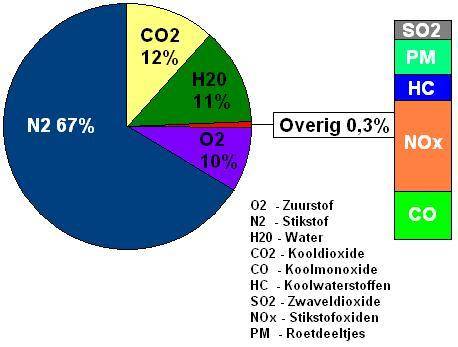

In the image on the right and the explanation below you can see what the exhaust gases of a diesel engine consist of.

- 67% Nitrogen (N2)

- 12% Carbon Dioxide (CO2)

- 11% Water (H2O)

- 10% Oxygen

- 0,3% other substances, including soot particles (PM), Hydrocarbons (HC), Nitrogen oxides (NOx), Carbon monoxide (CO).

To reduce NOx emissions, diesel engines are increasingly using a SCR catalytic converter with an AdBlue dosing system.