Subjects:

- Clutch and pressure group

- Thrust bearing

- Mechanically operated clutch system

- Hydraulically operated clutch system

- Clutch failure

Clutch and pressure group:

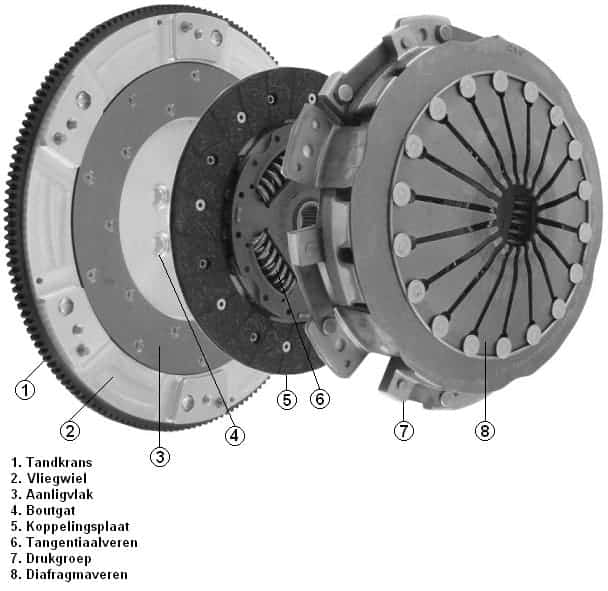

The purpose of the coupling is to be able to connect and disconnect the motor with the driven wheels at the desired moment. The clutch consists of a clutch plate and a pressure group (see picture below). These are attached to the flywheel of the engine. In the rest position, the pressure group clamps the clutch disc against the flywheel. The clutch disc lining (5) then clamps against the contact surface (3) of the flywheel.

The moment the clutch pedal is pressed, the release bearing presses against the diaphragm springs of the pressure group. This happens on the inside of the diaphragm springs. Due to the diaphragm action, the outside of the pressure group springs out. The link is “disconnected”. When the clutch pedal is released again, the thrust bearing will exert less and less force on the diaphragm springs. These springs return to the neutral position, causing the outside of the diaphragm to move towards the clutch disc again. The clutch is again enclosed between the pressure group and the flywheel. By doing this very gradually and thus letting the clutch slip between the flywheel and the pressure group, the car starts to move. If this position is held for too long, or if the engine speed is too high, the clutch disc lining will wear faster or even be damaged.

The clutch disc is a wearing part. The characteristics of the wear are described at the bottom of this page. When replacing the clutch, 99% of cars will have to disassemble the gearbox. This is a lot of work for most cars. Sometimes the subframe also has to be disassembled. In some cases it is even useful to disassemble the complete engine block with the gearbox attached as a whole.

When a clutch plate is replaced, it is common to also replace the pressure group and the release bearing. It is unwise to leave these in place, because the pressure group is also subject to wear; think of the compression and extension of the diaphragm springs and the contact surface on the back of the pressure group against which the clutch plate is pressed.

Never apply too much grease to the drive shaft or other parts of the clutch. Some manufacturers even prohibit the use of grease! There is soon too much grease on it, where dust from the clutch plate lining will quickly stick to it.

After disassembly, clean everything very well and free of grease. That is more important than applying fat. If you still want to apply it, a very small layer should be applied to the spline of the input shaft. So minimal that it is almost invisible.

Thrust bearing:

The release bearing is mounted with springs on the inside of the gearbox housing and slides with it on the teeth of the input shaft. On one side of the release bearing is the lever and on the other side are the diaphragm springs of the pressure group. When the motor is running, the pressure plate with the diaphragm springs will rotate at the same speed. The crankshaft drives the flywheel and thus also the clutch directly. The lever does not turn. It only makes a back and forth movement when the clutch pedal is depressed or released. The release bearing makes it possible to have the “stationary” lever press the rotating diaphragm springs. Between the two parts of the thrust bearing are ball bearings, so that these parts can move relative to each other.

The thrust bearing shown is a pivot butcher, which is described on the page bearings.

Mechanically operated clutch system:

With the mechanical control system, bowden cables used. Rods were also used in the past, but because there were too many disadvantages, such as the reaction forces that are strongly transmitted to the clutch pedal and play that develops at the pivot points over time, this is no longer used today. We will not go into this further. A Bowden cable does not have these disadvantages. The disadvantages of this cable are that stretching occurs in the cable over time, making adjustment necessary. Furthermore, with aging and partly due to dirt and moisture, the cable will become increasingly heavier.

Operation: When the clutch pedal is depressed, the pivoting movement through the pivot point above the pedal pulls the inner cable in Bowden cable. This will cause the clutch lever to pivot around the pivot point (which is a fixed point in the gearbox housing), pushing the release bearing inward. The release bearing presses against the diaphragm springs of the pressure group, releasing the clutch disc. The link is then disconnected.

The cable can often be adjusted. Sometimes the cable is equipped with a self-adjusting mechanism. With aging, the cable can become heavy, or can start to crack. It sometimes helps to lubricate the cable. This can be done by running a little lubricant into an opening of the Bowden cable and operating the cable frequently. The best solution is to replace the cable.

Hydraulically operated clutch system:

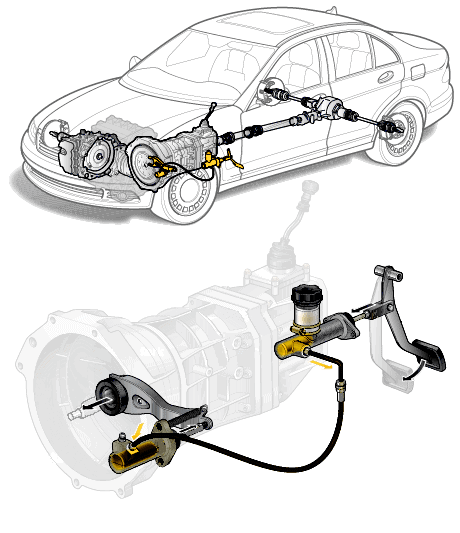

In the hydraulic clutch system, the force of the brake pedal is transferred by means of fluid (usually brake fluid) applied to the pressure group. The big advantage is that the clutch can be operated more smoothly than with the mechanical system with the clutch cable. Because brake fluid is used, the circuit is linked to the braking system. Because a special flow valve has been placed, the braking system will never run out of fluid in the event of a leaking clutch system. When changing the brake fluid of the brake system, the clutch fluid can also be changed at the same time by opening the nipple on the clutch cylinder on the gearbox.

Operation: When the clutch pedal is depressed, fluid pressure builds up in the clutch cylinder behind the brake pedal (the command cylinder). This fluid pressure travels through the hose to the clutch cylinder on the gearbox housing (also known as the master or slave cylinder). The piston of this working cylinder presses against the underside of the lever. Because the top is mounted against a fixed point of the gearbox housing, the middle part will move to the left. The release bearing is mounted in the middle part, which will compress the diaphragm springs when actuated. As with the diaphragm springs of a mechanically actuated system, the clutch disc will release when actuated.

When the clutch pedal is raised again is left, the diaphragm spring will push the release bearing out again and the clutch disc will again be wedged between the clutch pressure plate and flywheel. In that case, the transmission is reconnected to the engine and can be driven.

The image below shows a vehicle with the engine and gearbox mounted longitudinally. The gear lever is located directly above the gearbox, because the gearbox is located under the center console in the interior.

Clutch failures:

A clutch is a wearing part. With a good driving style, the clutch can easily last 300.000 km. In people who let the clutch slip a lot and drive a lot in city traffic, the clutch can already go bad after a few tens of thousands of kilometers. If a clutch wears out, this can be indicated by the following points:

- Clutch pedal is very high; With a hydraulic clutch, this does not necessarily mean that the clutch is worn. If it also has a tendency to slip, it is wearing out. With a mechanical operation it can also mean that it is incorrectly adjusted. However, if the pedal is pressed with a small force and the clutch then slips, the clutch is worn out.

- Slipping clutch; At full acceleration, the engine speed increases faster than the car accelerates. Usually this is accompanied by a burnt (clutch plates) air. This clutch is very worn and will soon no longer be possible to drive.

- When accelerating into 4th (or higher gear) and lightly touching the clutch pedal, the clutch already starts to slip; The clutch is worn out.

- When accelerating into a higher gear (4th or higher), pressing and releasing the clutch while holding the accelerator pedal should quickly engage the clutch again. If the clutch continues to slip for an extended period of time, it will become worn.

- Clutch is heavy, the pedal has to be pressed very strongly; the pressure group is often the cause of this. This is often a combination of a worn clutch and pressure group and will have to be replaced.

- Clutch does not release when fully depressed clutch pedal; Probably a problem in the clutch cylinder or in the pressure plate. A diaphragm spring may be broken in the pressure plate.

- Clutch vibrates/dribbles when cranked; This could be dirt on the clutch plate, a vitrified clutch or a dual mass flywheel that has excessive play.

If the clutch slips little (ie a good driving style), the plates can get dirty. By letting the clutch slip briefly and powerfully, the plates burn clean again. While driving, put the car in high gear (4 or 5), depress the clutch halfway, and accelerate. Do not do this for too long, because then the plate may burn. If done carefully, the dirt will burn off the clutch plate and the vibration may be gone for good. - If a scraping sound is heard when the vehicle is in neutral and the clutch is not engaged; When the clutch is pressed, the noise is gone. Then this is probably the release bearing making noise. The release bearing is located between the lever and the pressure group. When unloaded, it may rattle. Replacing this part is the only solution.