Subjects:

- Preface

- Capillary

- Thermostatic Expansion Valve (TEV)

- Possible malfunctions

Preface:

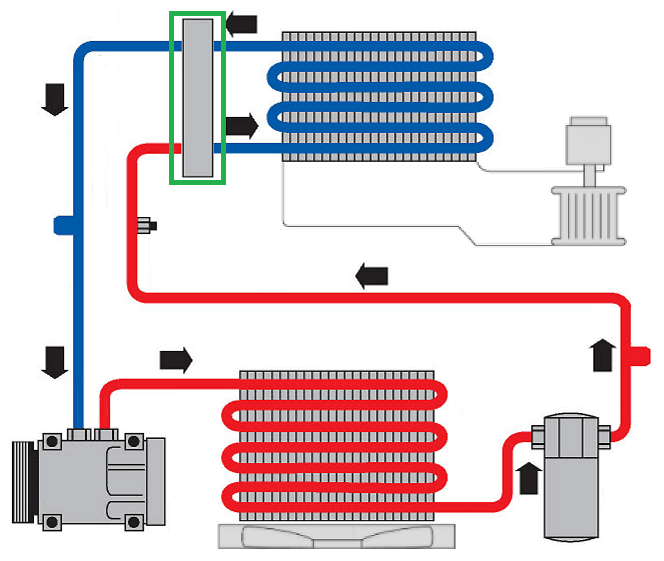

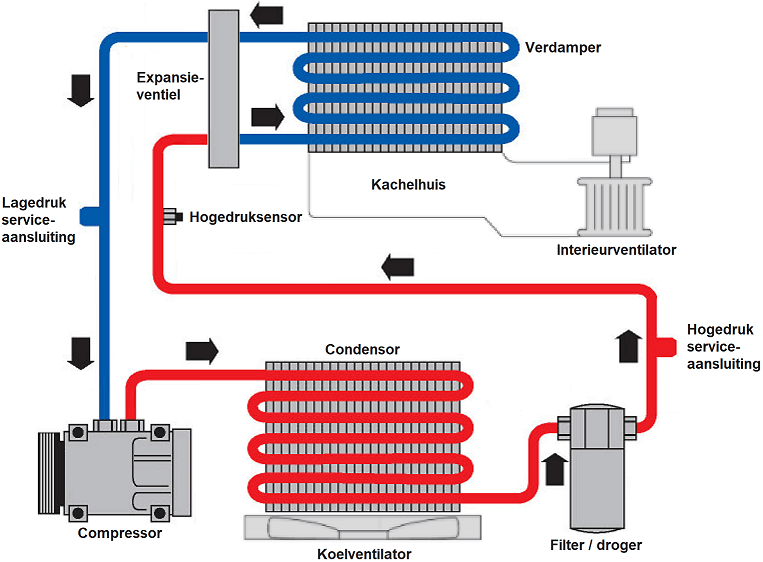

An expansion valve is an essential part of air conditioning systems. It functions as a restriction in the line between the dryer/filter element and the evaporator, resulting in a transition from high to low pressure. In the image below, the expansion valve (designed as a block valve) is framed in green.

After the refrigerant from the compressor has passed the filter/dryer element, it reaches the expansion valve at a pressure of approximately 15 bar and a temperature of approximately 45 degrees Celsius. The refrigerant flows from the expansion valve into the evaporator. As the refrigerant flows through the restriction of the expansion valve, it undergoes a significant reduction in pressure. When the pressure drops, the boiling point of the refrigerant also drops. The refrigerant begins to evaporate and change from liquid to gaseous form. In this phase change from liquid to vapor, the refrigerant absorbs heat from the environment. This released heat is extracted from the passing air flowing through the evaporator, resulting in the cooling of the air. This cooled air is led into the interior, resulting in the cooled and dried air that an air conditioner produces.

There are different types of expansion valves, namely the capillary expansion valve and the thermostatic expansion valve (TEV), which is also often called a “block valve”. These are described below.

Capillary:

In air conditioning systems you sometimes come across a simple type of expansion valve called a capillary or orifice. In newer vehicles, expansion valves are usually no longer equipped with a capillary, but with a thermostatic (controlled) expansion valve.

With an air conditioning system with capillary, the cooling capacity cannot be adjusted accurately. If the pressure becomes too high or the evaporator becomes too cold, the air conditioning compressor usually switches off.

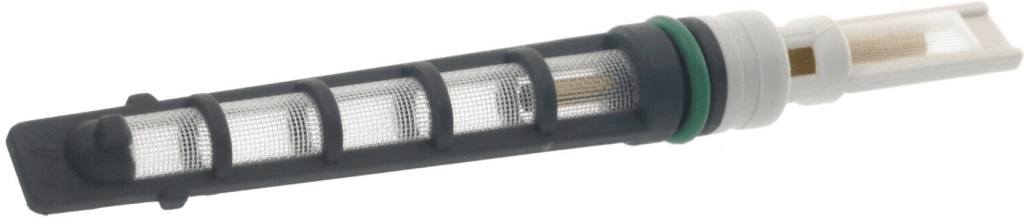

The outside of the capillary expansion valve is usually made of plastic and there is a special tube inside. There are filters before and after that tube. The capillary causes a sudden drop in pressure, which quickly drops the boiling temperature of the refrigerant and changes it from liquid to gas. How the capillary is constructed determines how much the pressure drops, and this affects the temperature when the refrigerant enters the evaporator. The capillary can be found in different sizes, and installing one with different dimensions will change the cooling capacity of the system. If there is less evaporation in the evaporator, this usually means less cooling.

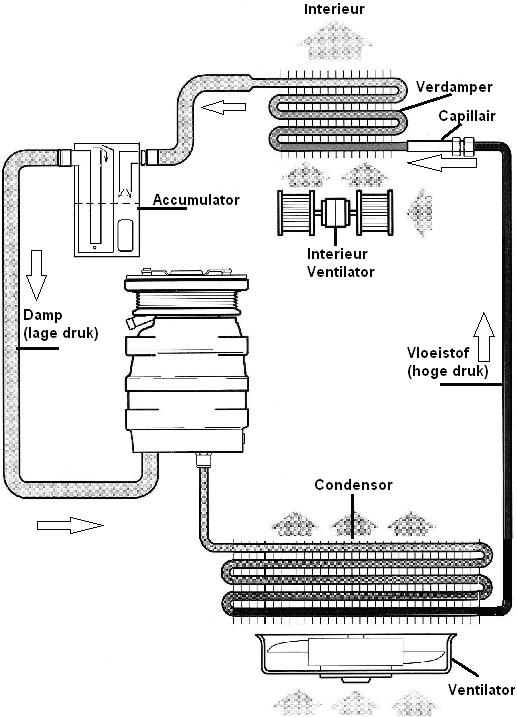

In air conditioning systems with a capillary, we usually also find an accumulator in the low-pressure section. This prevents liquid from being sucked in by the compressor, because the capillary has a fixed opening. The accumulator also has other important tasks, such as filtering, removing moisture (drying) and storing refrigerant. The refrigerant enters the accumulator from the evaporator as a gas, with some liquid droplets. A separation screen in the accumulator ensures that the liquid particles sink down the side. A desiccant removes moisture from the refrigerant. In addition, the vapor is sucked in at the top by the compressor through a small opening of about 1 millimeter, taking with it a little oil.

The following malfunctions can occur in air conditioning systems with a capillary tube:

- Clogging: If the capillary becomes clogged by contaminants in the refrigerant, this can reduce cooling capacity;

- Incorrect dimensions: In certain cases it may be necessary to replace the capillary with one of different dimensions to adjust the cooling capacity of the system. This may be required for system changes or if the original specifications do not meet the required performance, such as a freezing evaporator or insufficient cooling.

- Systematic Problems: If the air conditioning system has persistent performance problems and other components have been checked and are in good condition, the capillary may be a possible cause. The capillary may be damaged and this cannot be easily seen.

Thermostatic Expansion Valve (TEV):

An air conditioning system that we usually find in modern vehicles is a system with a thermostatically controlled expansion valve, abbreviated as TEV. The thermostatic expansion valve replaces the system with a capillary and is basically a constriction whose opening size is controlled by the temperature of the gas flowing from the evaporator.

There are different versions. In addition to the replacement of the capillary, the filter/dryer element is also different. The filter/dryer is located directly after the condenser and deals with the refrigerant in liquid form. The temperature is measured after the evaporator. If the evaporator temperature becomes too high because there is not enough refrigerant flowing through it, the opening is made larger, allowing more refrigerant to the evaporator and the temperature drops again. The thermostatic expansion valve keeps the temperature (and pressure) constant within certain limits. This also means that we can be sure that the refrigerant in vapor form is sucked in by the compressor, so that an accumulator no longer needs to be used in the low-pressure section.

The thermostatic expansion valve can be divided into three types:

- Expansion valve with remote sensor (remote bulb control) with internal or external pressure equalization.

- Block valve with internal or external membrane.

- Electronically controlled expansion valve.

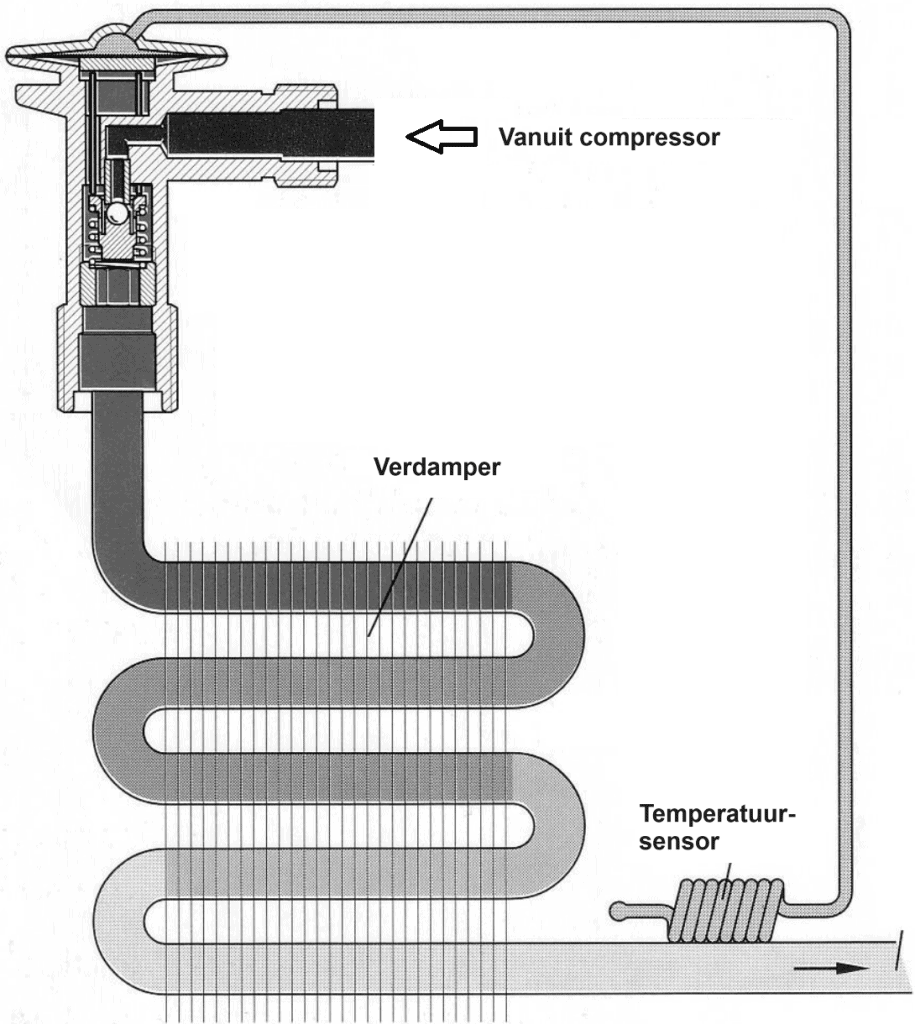

Thermostatic expansion valve with remote sensor and internal pressure equalization:

The thermostatic expansion valve consists of two parts, namely the measuring part and the sensor or bulb, which is connected to the actual expansion valve. The measuring section is filled with gas and is located at the outlet of the evaporator. When the temperature at the outlet of the evaporator rises because too little refrigerant passes, the gas expands and the pressure increases. The pin then pushes the ball free, causing more refrigerant to flow into the evaporator and the temperature at the exit to drop again. The ball is released as soon as the force on the membrane from the sensor exceeds the sum of the spring force and the compressive force of the refrigerant on the inlet side of the evaporator. When the temperature after the evaporator becomes too low, the opposite happens. The spring force forces the ball back onto the seat, the opening narrows and the flow of refrigerant is reduced. The TEV valve therefore maintains the temperature of the refrigerant constant. The thermostatic expansion valve measures the temperature and converts it into pressure. The pressure control activates the valve.

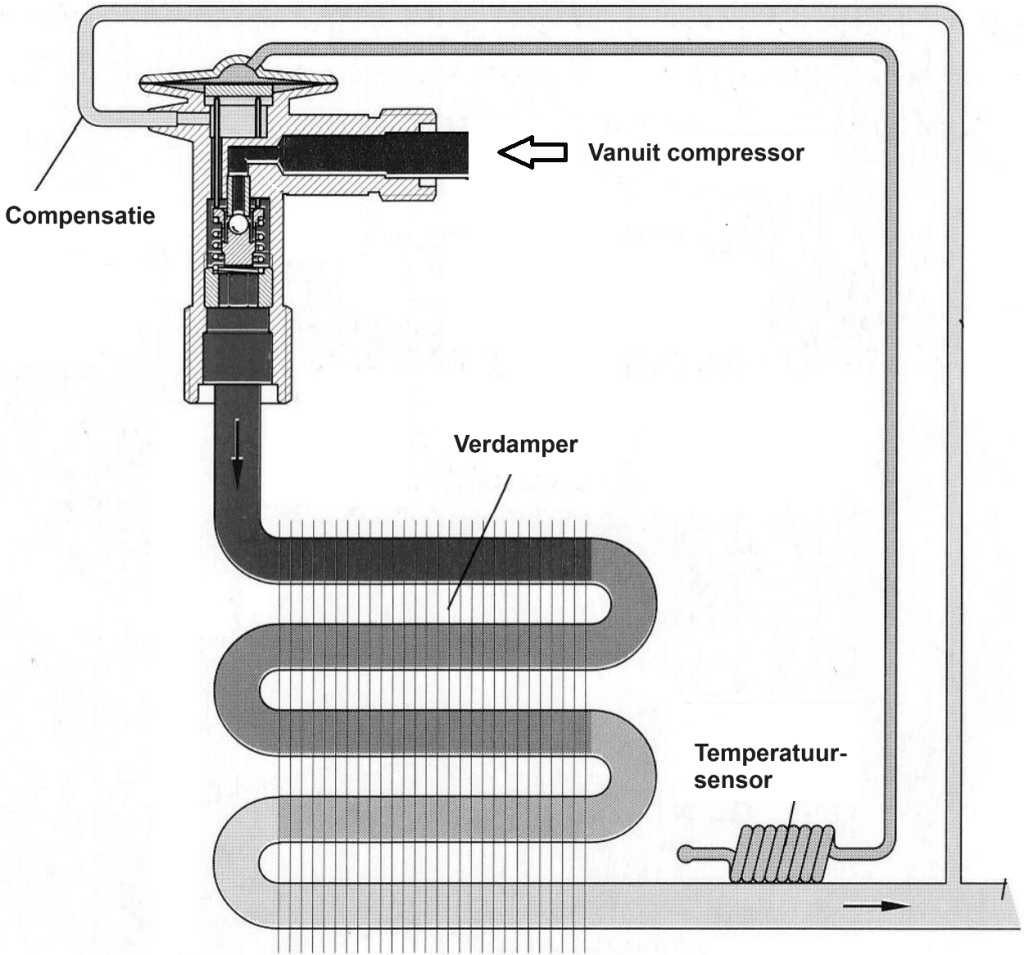

Thermostatic expansion valve with remote sensor and external pressure equalization:

Pressure equalization has to do with the pressure under the diaphragm. If the space under the membrane is connected to the inlet side of the evaporator, we do not take into account the pressure loss that occurs in the evaporator. After all, the temperature measurement takes place on the outlet side of the evaporator, while the control takes place on the inlet side. When the pressure loss exceeds 0,2 bar, it is recommended to use an expansion valve with external pressure equalization. If the space under the membrane is connected to the outlet side of the evaporator, the pressure loss is compensated. External pressure equalization is usually applied to larger systems.

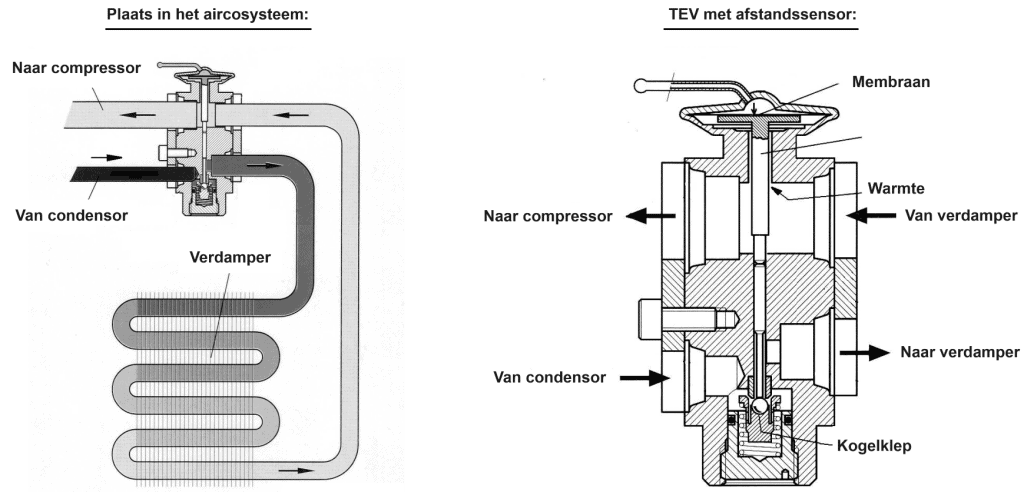

Block valve with external control diaphragm

The block valve is installed on the inlet and outlet pipes of the evaporator. The inlet line is located next to the outlet line at the evaporator. At the bottom of the block valve, the refrigerant enters in liquid form from the filter/dryer (condenser) and passes through the ball valve on its way to the evaporator. There is a fixed amount of gaseous refrigerant above the membrane. This gas will assume the temperature of the gas coming from the evaporator. As the temperature increases, the increase in pressure will push the pin downward, resulting in a larger flow opening in the supply line. This allows more refrigerant to enter the evaporator, lowering the temperature. In reverse situations, the ball valve will close, allowing less refrigerant to enter the evaporator and causing the temperature to rise.

Block valve with internal regulating membrane:

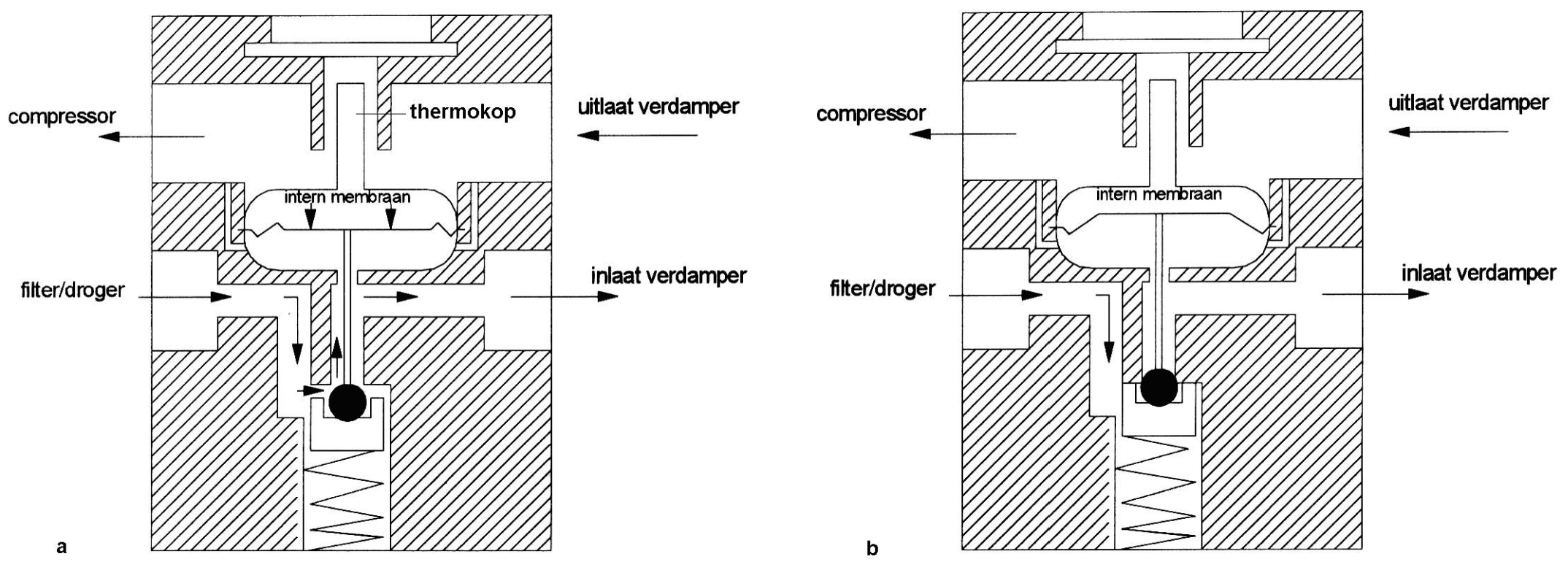

In the block valve with an internal control membrane, there is a thermohead with refrigerant on the outlet side of the evaporator. The refrigerant in the thermo cup assumes the temperature of the refrigerant leaving the evaporator. At high temperatures, the refrigerant expands, causing the capsule diaphragm to push the rod down and widen the ball valve opening. Conversely, a lower temperature will cause the membrane to rise, making the opening smaller. These two situations are shown in the images below.

Electronically controlled thermostatic expansion valve:

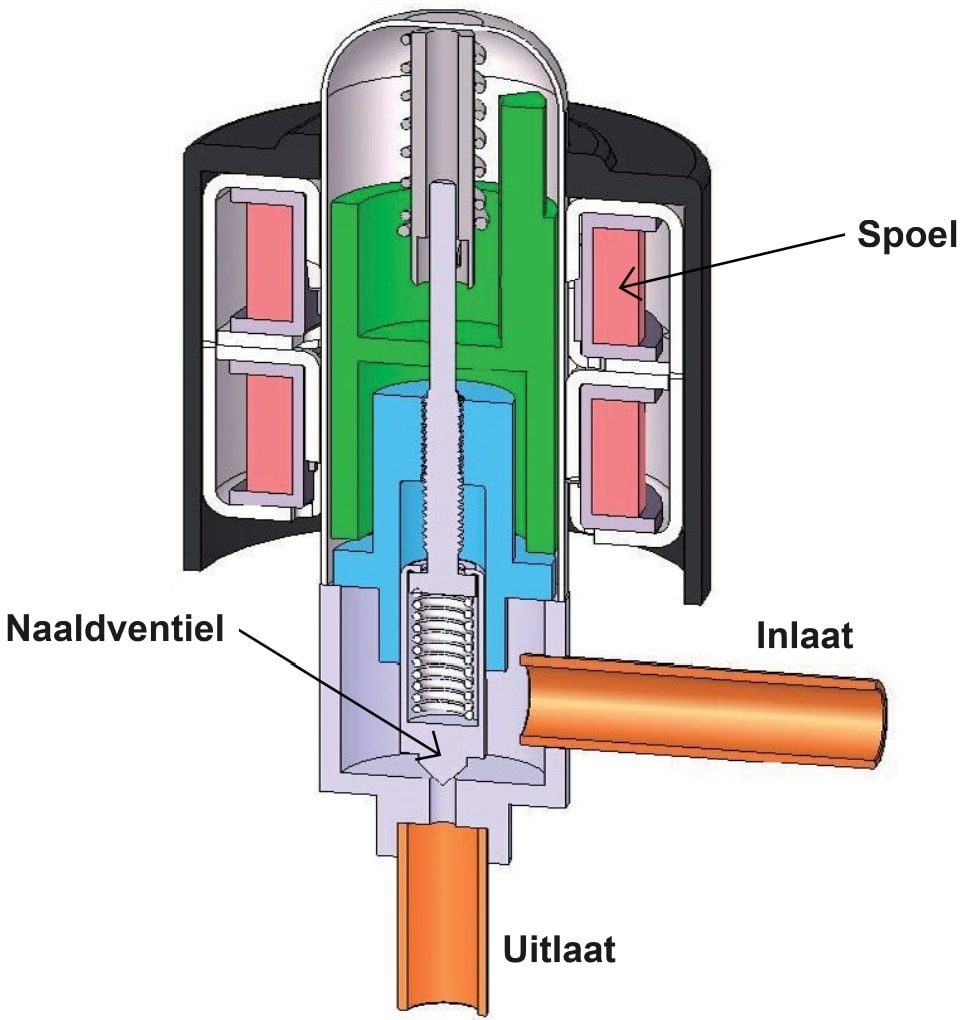

The Electronically Controlled Expansion Valve (abbreviated as EEV) can be controlled using the ECU of the climate control. A stepper motor can be used for this. This stepper motor makes it possible for the needle to increase or decrease the opening in small steps. Depending on the desired temperature in the interior, the ECU can very quickly regulate the capacity by using the electrically controlled air conditioning compressor and the expansion valve.

Possible malfunctions:

In the workshop we encounter problems with the expansion valve. Problems usually arise due to contamination, causing the expansion valve to become clogged or remain open.

- The valve is clogged:

Clogging is caused by contaminants in the refrigerant. As a result of the blockage, too little refrigerant enters the evaporator, which leads to an increasing pressure with the risk of the compressor overheating. - The valve remains open:

Leaving the valve open allows too much refrigerant to enter the compressor. If not all the refrigerant in the evaporator has turned into gas, there is a chance that an (excessive) amount of liquid refrigerant will end up in the compressor, causing the compressor to experience a liquid shock.

Contamination is easy to prevent: replace the filter/dryer periodically.

Related page: