Introduction:

A vehicle contains a large number of temperature sensors:

- coolant temperature;

- oil temperature;

- interior / outside air and intake air temperature (possibly integrated in the mass air flow sensor);

- exhaust gas temperature;

- battery temperature in hybrid or fully electric vehicles.

The above temperature sensors provide the control unit for the respective system with information. For example: the engine control module uses the signal from the coolant temperature sensor to adjust various functions, such as fuel injection, ignition, idle speed control, EGR operation (if applicable), and cooling fan control based on temperature. At a low temperature, enrichment takes place and the EGR is activated to bring the engine to operating temperature more quickly. At a higher temperature, the control unit activates the cooling fan relay. The most commonly used temperature sensors operate on the NTC principle.

In addition to sensors that send information to the control unit, there are also safety sensors that function without additional electronics. In such a PTC sensor, the Ohmic resistance increases as the temperature rises. An electric motor (such as a windshield wiper or window motor) and a mirror heating element are equipped with a PTC sensor. In some cases, a PTC sensor is used as a temperature sensor, but most often we encounter the NTC type.

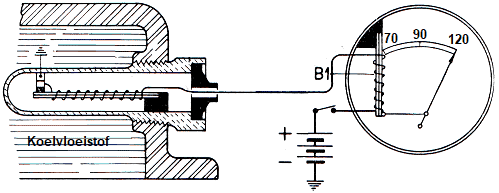

Classic coolant temperature gauge:

In older cars without control units and NTC temperature sensors, the coolant temperature sender operates with a bimetal element. The illustration shows the components of the bimetal gauge. The gauge is connected to a stabilized voltage supply of around 10 volts. The bimetal in the gauge bends as soon as a (higher) current flows. This causes the needle to move accordingly.

There is a temperature sensing element with a bimetal in the engine block.

The temperature sensor comes into contact with the coolant in the engine.

The temperature at which the contact points open depends on the coolant temperature and the current. The average current then depends on the engine temperature. In some cases, the needle points to the maximum position when the ignition is off. The bimetal is then straight.

NTC temperature sensor:

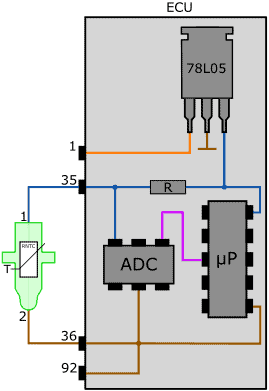

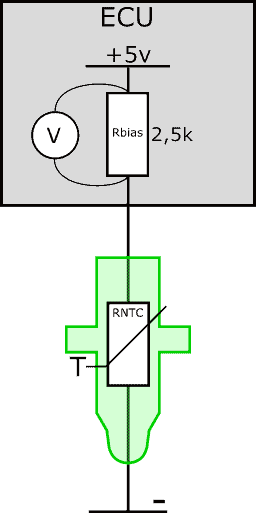

The following image shows a simplified diagram of the ECU and the temperature sensor. The sensor (RNTC) has two wires. The positive wire is connected to the ECU and the negative wire to ground. Inside the ECU, there is a bias resistor. The bias and NTC resistors are connected in series. The ECU supplies the series circuit with a voltage of 5 volts.

In a series circuit, the voltage is distributed across the resistors. Part of the 5 volts is dropped across the bias resistor, and the other part across the NTC sensor.

The bias resistor has a fixed resistance value; usually around 2500 ohms (2.5 kilo-ohms). The resistance of the NTC depends on the temperature. The voltage that is dropped across the NTC resistor therefore depends on the temperature.

The ECU measures the voltage drop across the bias resistor. When the temperature changes, the voltage across RNTC changes, and so does the voltage across the bias resistor. In a series circuit, the voltages are divided over the resistors; if RNTC takes up 0.3 volts more, then the voltage across Rbias drops by 0.3 volts.

The voltage measured across the bias resistor is converted by the ECU into a temperature. In fact, we now apply the NTC characteristic, with voltage on the X-axis instead of temperature.

At higher temperatures, the resistance changes less. The curve in the characteristic drops more sharply between 0 and 20 degrees Celsius than between 40 and 60 degrees Celsius. For this reason, manufacturers often use a second bias resistor for the coolant temperature sensor. The bias resistors are connected in parallel and each has a different resistance value.

As the temperature increases, the ECU switches to the other bias resistor. In this way, a second NTC characteristic curve is created. The second characteristic will provide a larger resistance change at high temperature. This allows for measurement across a wider range and enables accurate temperature determination during both the warm-up phase and at operating temperature.

The following image shows the actual circuit inside the ECU with the 5-volt voltage stabilizer (78L05), bias resistor (R), the analog-to-digital converter (A/D converter), and the microprocessor. More information about analog signal transmission such as from the temperature sensor can be found on the page: sensor types and signals.

Temperature sensor diagnostics:

In the event of faults related to the coolant temperature sensor, the following issues may occur:

- poor engine starting due to, for example, extra fueling for a cold engine, while the engine is actually already warm;

- overheating: due to a too low value, the PWM-controlled cooling fan switches on too late or not at all;

- the engine does not idle steadily after a cold start;

- as the engine continues to warm up, the idle speed increases;

- exhaust emissions are out of specification;

- black smoke due to a too rich mixture;

- hesitation and misfiring when the engine is cold;

- the air conditioning cannot be activated.

Often, these issues occur in combination with a check engine light, but this is not always the case. If there is a fault in which the coolant temperature sensor signal remains within the allowed tolerance, no trouble code will be generated.

In reality, the software in the engine ECU constantly checks whether the signal is plausible: in the case of significant deviations compared to other temperature sensors, or a (too) rapid rise or fall in temperature, the signal is considered “not plausible”. This will result in a fault code.

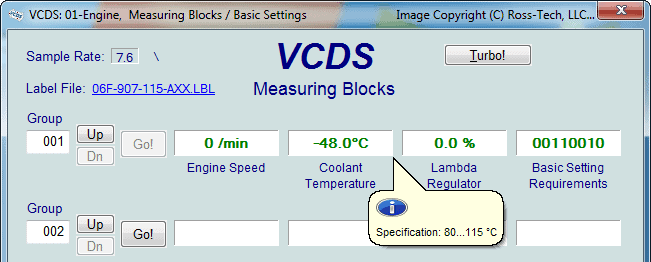

Using diagnostic equipment (often an inexpensive OBD reader or an interface with software for smartphones is sufficient), the coolant temperature can be read out.

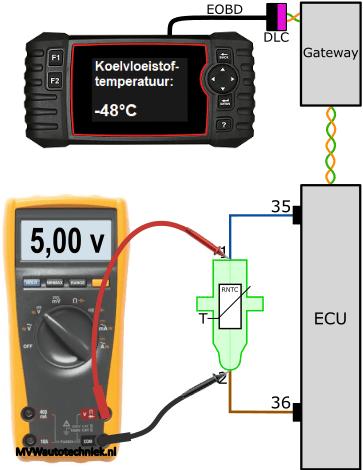

The image shows a temperature of -48 °C.

The diagnostic program (in this case, the measured value blocks in VCDS) often also provides a reference value to which the temperature should correspond. In the current operating conditions, the temperature should be between 80 and 115 °C.

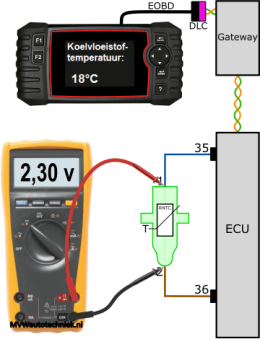

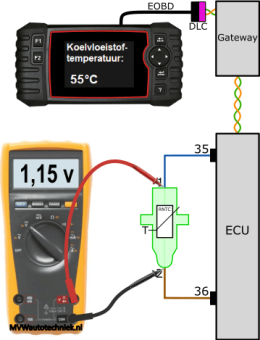

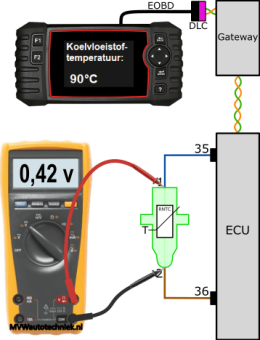

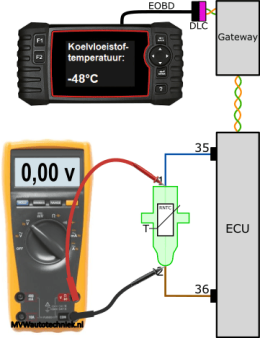

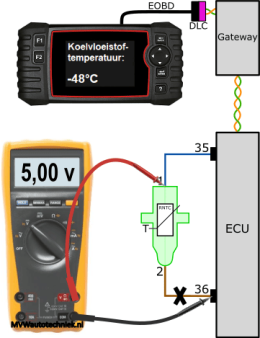

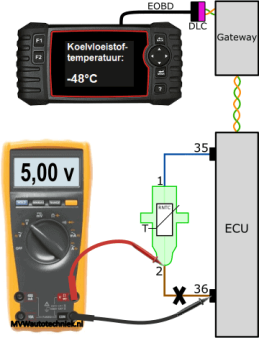

If it is suspected that a sensor value is incorrect, you can check the voltages with a multimeter. First, measure the voltages across the sensor at three different temperatures. In the following three images, a scan tool is shown that is connected via the DLC (Data Link Connector) to the gateway using the CAN bus. The gateway also communicates via CAN bus with the engine ECU.

The section “NTC temperature sensor” above describes that the temperature sensor is in series with a bias resistor in the ECU. The 5-volt supply is divided between the bias resistor and the NTC resistor in the sensor housing. When a voltage of 2.3 volts is measured across the sensor, the voltage across the bias resistor is 2.7 volts (2.3 + 2.7 = 5 volts). The 2.7 volts is converted by the A/D converter in the interface electronics of the ECU into a temperature. When the engine is warm, the voltage across the bias resistor increases; this can be seen in the last measurement. In this situation, this voltage amounts to 4.58 volts.

The images below show the live data and measurements during an open ground wire between the sensor and the ECU. The scan tool shows a temperature of -48 degrees Celsius: the ECU measures a voltage of 5 volts across the bias resistor. The ECU generates one or more trouble codes with descriptions of the sensor:

- signal implausible;

- signal below lower limit;

- short to positive.

As a result of the open circuit, no current flows, so the NTC does not drop any voltage. The voltage difference between pin 1 of the sensor and pin 36 of the ECU is 5 volts: this is the supply voltage for the sensor. Through pin 35, 5 volts is supplied. Since the sensor does not drop any voltage, we measure a 5-volt difference between pin 2 (ground connection) of the sensor and pin 36.

If a voltage of 5.0 volts is measured across the temperature sensor (see the following image), then the total supplied voltage is measured across the component. In this case, there is an open circuit inside the temperature sensor. The voltage drop across the positive and ground wires is 0 volts.

When the connector for the temperature sensor is removed and a multimeter is used on the connector, the reading on the multimeter will show the same value.

With the result of this measurement, it is clear that the temperature sensor needs to be replaced.