Subjects:

- Preface

- Passive sensors

- Active sensors

- Intelligent sensors

- Applications in automotive technology

- Measuring on sensors

- Signal transmission from sensor to ECU

- SENT (Single Edge Nibble Transmission)

- Power supply and signal processing

Preface:

Sensors measure physical quantities and convert them into electrical voltages. These voltages are processed in the microcontroller (ECU) and read as a “signal”. The signal can be judged by the magnitude of the voltage, or the frequency with which a signal changes.

Passive sensors:

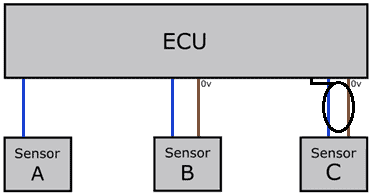

A passive sensor detects and measures a physical quantity and converts it into another physical quantity. An example of this is converting a temperature into a resistance value. A passive sensor does not generate any voltage itself, but responds to a reference voltage from the ECU. A passive sensor does not require a power supply to function.

Passive sensors usually have two or three connections:

- reference or signal wire (blue);

- ground wire (brown);

- shielded wire (black).

Sometimes a passive sensor contains only one wire: in that case the housing of the sensor serves as ground. A third wire can serve as a shield. The sheath is grounded via the ECU. The shielded wire is used especially for interference-sensitive signals such as from the crankshaft position sensor and the knock sensor.

An example of a passive sensor is a NTC temperature sensor. The reference voltage of 5 volts is used as a voltage divider between the resistance in the ECU and in the sensor, not as a supply voltage for the sensor. The height of the voltage between the resistors (depending on the NTC resistance value) is read by the ECU and translated into a temperature. The circuit with the resistors is explained in the section: “Power supply and signal processing” later on this page.

Active sensors:

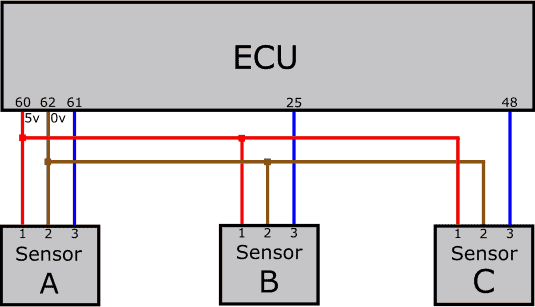

Active sensors contain an electrical circuit in the housing to convert a physical quantity into a voltage value. The electrical circuit often needs a stabilized supply voltage in order to work.

In most cases, this type of sensor has three connections:

- plus (usually 5,0 volts);

- pasta;

- signal.

The stabilized 5 volt supply is supplied by the control unit and used by the sensor to form an analog signal (between 0 and 5 volts). Often the plus and ground wires from the ECU are connected to multiple sensors. This can be recognized by the nodes to which more than two wires are connected.

The analog signal is converted into a digital signal in the ECU.

In the section “spanning supply and signal processing” we will discuss this in more detail.

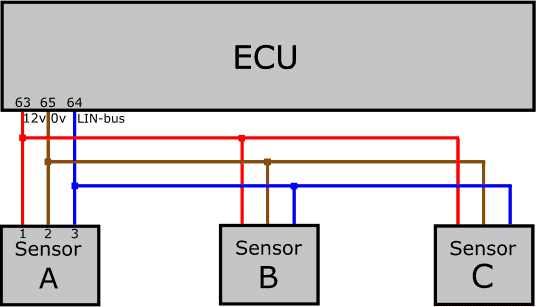

Intelligent sensors:

Intelligent sensors usually have three connections. As with the active sensors, there is a power wire (12 volts from the ECU or directly through a fuse) and a ground wire (through the ECU or an external ground point. An intelligent sensor sends a digital (LIN bus) message to the ECU and the other sensors. There is then a master-slave principle.

Internally in the sensor, an A/D converter converts an analog to a digital signal.

- Analog: 0 – 5 volts;

- Digital: 0 or 1.

In the LIN bus signal in recessive state (12 volts) there is a 1, and in dominant state (0 volts) a 0.

Applications in automotive technology:

In automotive technology we can make the following classification of the different types of sensors:

Passive sensors:

- knock sensor;

- crankshaft position sensor;

- Temperature sensor (NTC/PTC);

- Oxygen sensor (jump sensor / zirconium);

- Inductive height sensor;

- Switch (on/off)

Active sensors:

- Crankshaft/Camshaft Position Sensor (Hall);

- air mass meter;

- Wideband oxygen sensor;

- Pressure sensor (charge pressure / boost pressure sensor);

- ABS sensor (Hall / MRE);

- Acceleration/deceleration sensor (YAW);

- Radar / LIDAR sensor;

- Ultrasonic sensor (PDC / alarm);

- Position sensor (throttle valve / EGR / heater valve).

Intelligent sensors:

- Rain/light sensor;

- cameras;

- pressure sensor;

- Steering angle sensor;

- battery sensor

Measuring on sensors:

When a sensor is not working properly, the driver will in most cases notice this because a malfunction indicator lights up, or that something is no longer functioning properly. If a sensor in the engine compartment malfunctions, it could result in a loss of power and an illuminated MIL (engine malfunction indicator light).

When reading an ECU, a fault code may be displayed if the ECU recognizes the fault. However, the fault code does not lead directly to the cause in all cases. The fact that the sensor in question does not work may be because it is defective, but a problem in the wiring and / or plug connections cannot be ruled out.

It is also possible that the sensor gives an incorrect value, which is not recognized by the ECU. In that case, no fault code will be stored, but the technician must use the live data (see OBD page) have to look for readings that are out of range.

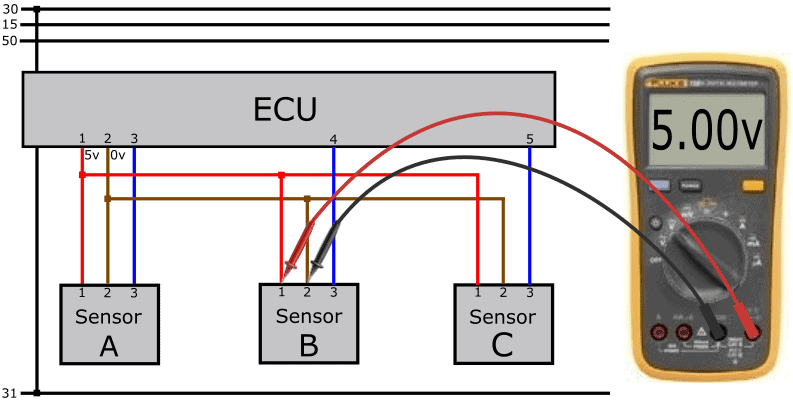

The following image shows a measurement from an active sensor. The power supply (the voltage difference on the plus and minus connections) of the sensor is checked with a digital multimeter. The meter reads 5 volts, so this is OK.

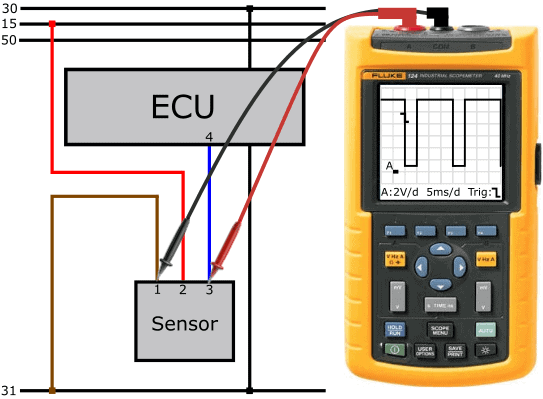

Signal voltages can be measured with a voltmeter or an oscilloscope. It depends on the signal type which meter is suitable:

- voltmeter: analog signals that are nearly constant;

- oscilloscope: analog signals and digital signals (duty-cycle / PWM).

With one or more measurements we can show that the sensor is not working properly (the signal delivered is implausible or the sensor does not give a signal), or that there is a problem in the wiring.

With passive sensors, in most cases a resistance measurement can be performed to check if there is an internal defect in the sensor.

Possible sensor wiring problems may include:

- interruption in the positive ground or signal wire;

- short circuit between wires or the body;

- contact resistance in one or more wires;

- bad plug connections.

On the page: troubleshooting sensor wiring we delve into seven possible faults that can occur in the wiring of sensors.

Signal transmission from sensor to ECU:

There are several methods to transfer signals from the sensor to the ECU. In automotive technology we can deal with the following signal types:

- Amplitude Modulation (AM); the height of the voltage provides information;

- Frequency Modulation (FM); the frequency of the signal provides information;

- Pulse Width Modulation (PWM); the time variation in the square-wave voltage (duty-cycle) provides information.

The following three examples show scope signals of the different signal types.

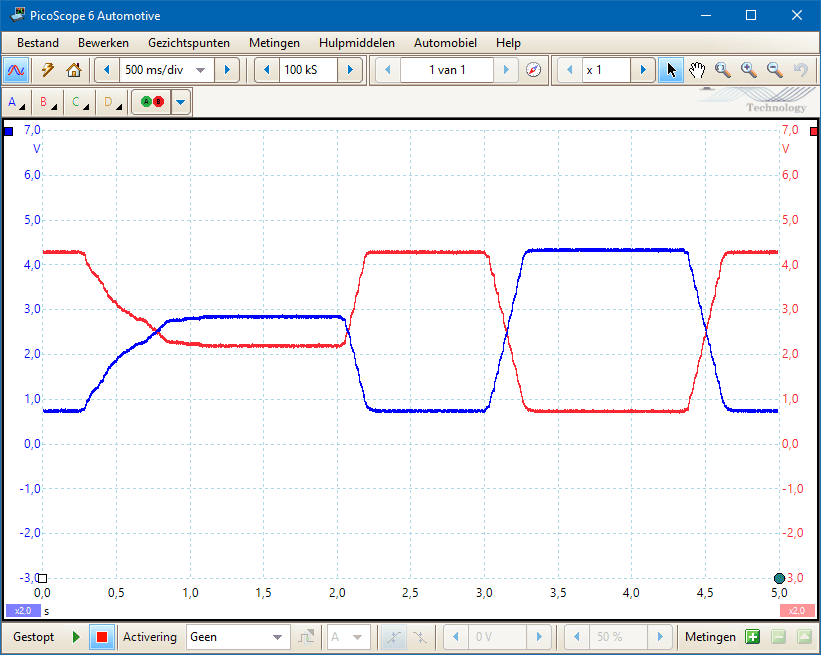

Amplitude Modulation:

With an AM signal, the level of the voltage transmits the information. The figure shows two voltages from the throttle position sensors. To guarantee reliability, the voltage curves must be mirrored relative to each other.

Tensions at rest:

- Blue: 700mV;

- Red: 4,3 volts.

From approximately 0,25 seconds after the start of the measurement, the accelerator pedal is slowly pressed and the throttle opens to 75%.

At 2,0 sec. the accelerator pedal is released and at 3,0 sec. is given full throttle.

Full throttle voltages:

- Blue: 4,3 volts;

- Red: 700 mV.

Frequency Modulation:

For sensors that transmit an FM signal, the amplitude (height) of the signal does not change. The width of the square-wave voltage transmits the information. The following image shows the signal from an ABS sensor (Hall). The wheel has turned during the measurement. With a higher rotational speed, the frequency of the signal becomes higher.

The voltage difference is caused by the change in the magnetic field in the magnetic ring, which is incorporated in the wheel bearing. The difference in height (low: magnetic field, high: no magnetic field) is only 300 mV. When setting the scope incorrectly (voltage range from 0 to 20 volts), the block signal is barely visible. For that reason, the scale has been adjusted in such a way that the block signal becomes visible, with the result that the signal is less pure.

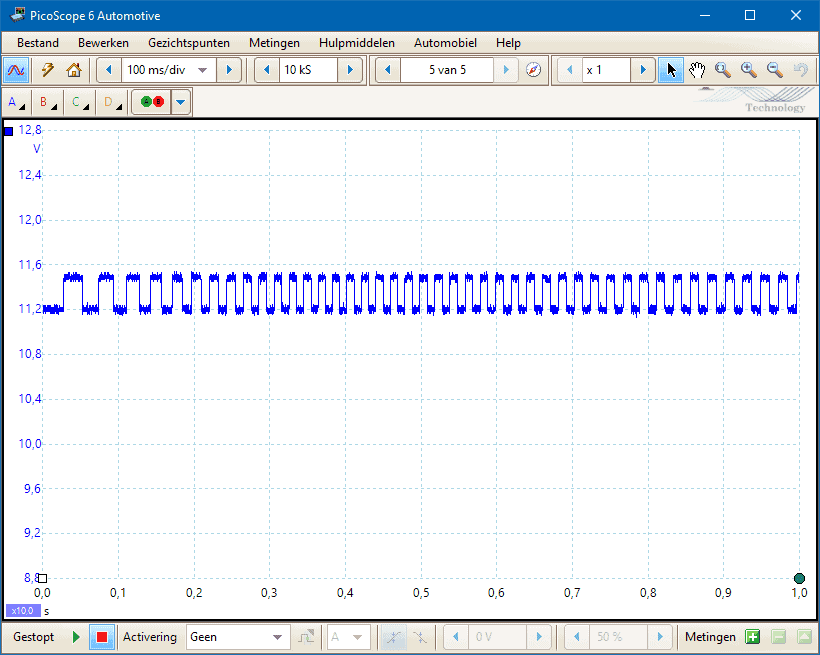

Pulse Width Modulation:

With a PWM signal, the ratio between high and low voltage changes, but the period time remains the same. This should not be confused with a square-wave voltage in an FM signal: the frequency changes and therefore also the period time.

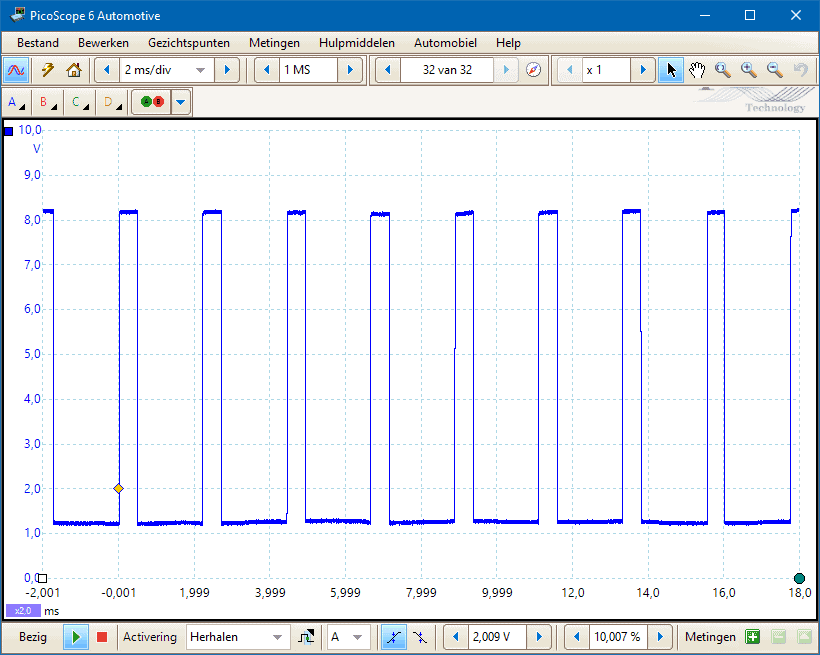

The next two images show PWM signals from a high pressure sensor in an air conditioner duct. This sensor measures the refrigerant pressure in the air conditioning system.

Situation during the measurement:

- Ignition switched on (sensor receives a supply voltage);

- Air conditioning turned off;

- Coolant pressure read with diagnostic equipment: 5 bar.

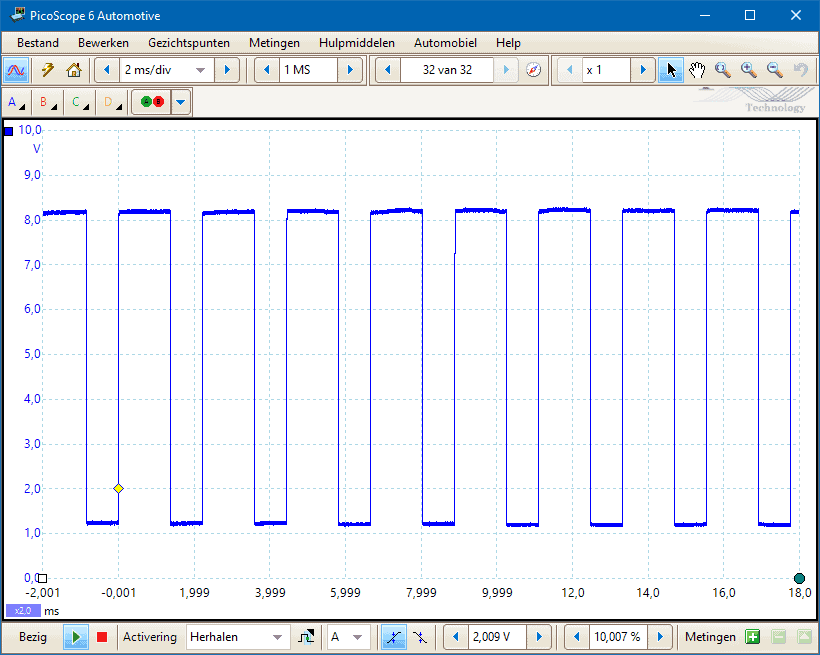

In the next scope image we see that the period time has remained the same, but the duty cycle has changed.

Situation during the measurement:

- Air conditioning turned on;

- High pressure has risen to 20 bar;

- Duty cycle is now 70%

Analog sensors can send a signal via AM. Such a voltage signal is sensitive to voltage loss. A transition resistance in a wire or plug results in voltage loss, and therefore also a lower signal voltage. The ECU receives the lower voltage and uses the signal for processing. This can cause malfunctions because multiple sensor values no longer correspond with each other, resulting in:

- Two outdoor air temperature sensors that simultaneously measure a different temperature. Although a small margin of error is acceptable and the ECU can adopt the average value, too large a difference can lead to a fault code. The ECU recognizes the deviation between the two temperature sensors.

- an incorrect injection duration because the signal from the MAP sensor is too low and the ECU therefore interprets an incorrect engine load. In that case, the fuel injection is too long or too short, and the fuel trims will correct the mixture based on the lambda sensor signal.

Voltage loss does not play a role in a PWM signal and/or SENT signal. The ratio between rising and falling edges is a measure of the signal. The level of voltage does not matter. The duty cycle can be 40% at a voltage that varies between 0 and 12 volts, but the ratio is still 40% if the supply voltage drops to 9 volts.

SENT (Single Edge Nibble Transmission)

The sensor signals mentioned above have been a household name in passenger and commercial vehicles for years. In the newer models we increasingly see sensors that use the SENT protocol. This sensor looks like a usual active sensor, both in reality and in the diagram.

With passive and active sensors, information transfer takes place via two wires. In the case of a MAP sensor for example: one between the NTC sensor and the ECU and the other between the pressure sensor and the ECU. The sensor electronics of a SENT sensor can combine the information transfer from multiple sensors, reducing the number of signal wires. The signal transmission is also not affected in the event of voltage loss over the signal wire, just like with a PWM signal.

A sensor using the SENT protocol, like an active sensor sending an analog or digital signal, has three wires:

- Supply voltage (often 5 volts)

- Signal

- Mass.

Sensors with the SEND protocol send a signal as “output”. There is therefore no bidirectional communication, as is the case with, for example, LIN bus communication between sensors.

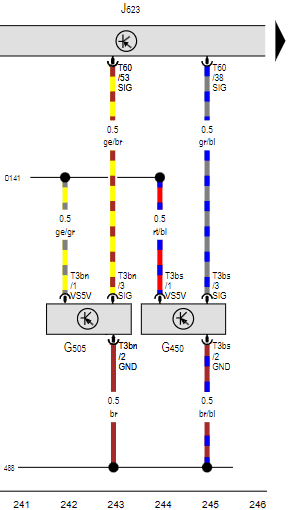

In the diagram on the right we see the differential pressure sensor (G505) of a VW Passat (built in 2022). In the diagram we see the usual indications of the power supply (5v), ground (GND) and signal (SIG). This pressure sensor converts the pressure into a digital SENT signal and sends it to pin 53 on connector T60 in the engine ECU.

The differential pressure sensor in the example above sends only one signal via the SENT protocol over the signal wire. Multiple sensors can be connected to one signal wire using SENT. This can be applied, among other things, to a MAP sensor (air pressure and air temperature) and to an oil level and quality sensor.

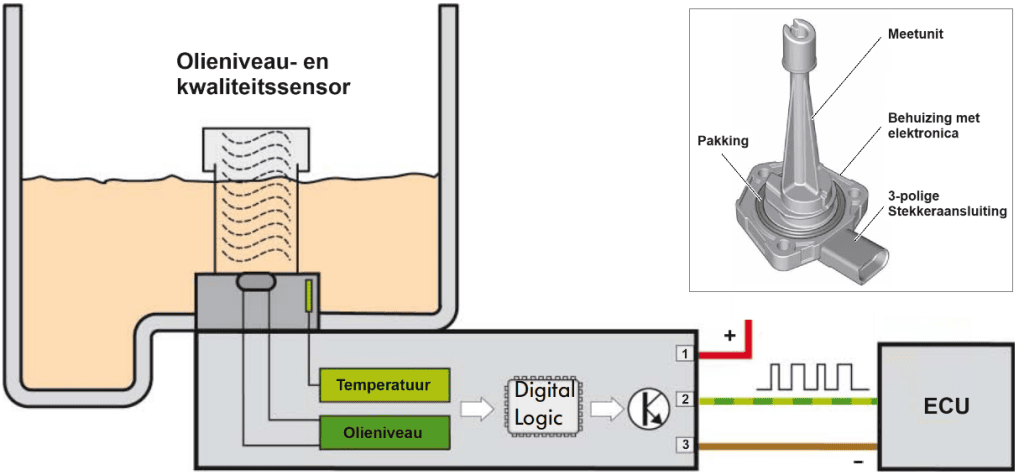

In the following image we see an oil level and quality sensor mounted in the oil pan of a combustion engine. Both measuring elements are located in the engine oil.

The sensor is supplied with 12 volts, receives its ground via the ECU and sends the signal to the ECU using SENT.

The microcontroller in the housing digitizes the message (see: “digital logic” in the figure) in which both the oil temperature and the oil level are included in the SENT signal.

Below we look at the structure of a SENT signal.

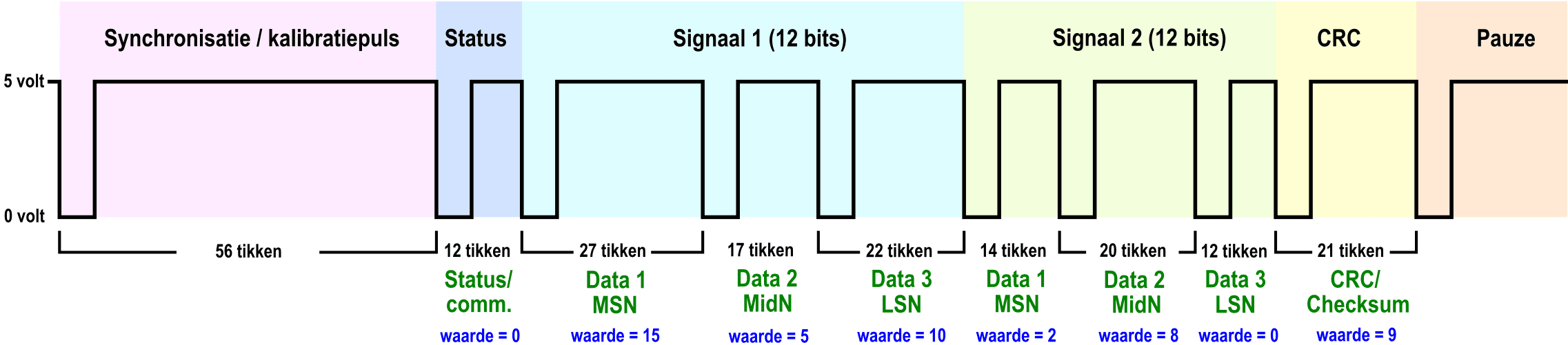

A SENT signal is made up of a series of nibbles (groups of four bits) that transfer information by sending voltages between 0 and 5 volts. Here is a brief description of how a SENT signal is constructed. The image of the message structure is shown below.

- Synchronization / Calibration Pulse: this is often the start of the message. This pulse allows the receiver to identify the beginning of the message and synchronize the timing of the clock;

- Status: this part indicates the condition of the information sent, for example whether the data is correct or whether there are problems with it;

- Message Start Nibble (MSN): This is the first nibble and indicates the beginning of a SENT message. It contains information about the source of the message and the timing of the data transfer.

- Message Identifier Nibble (MidN): This nibble follows the MSN and contains information about the type of message, the status of the message, and any error detection or error correction information.

- Data Nibbles: After the MidN follows one or more data blocks, each consisting of four data nibbles. These data blocks carry the actual data being sent. They contain information such as sensor data, status information or other useful data.

- Cyclic Redundancy Check (CRC): In some cases, a CRC nibble can be added to the end of the message to aid error detection. The CRC nibble is used to check whether the received data has been received correctly.

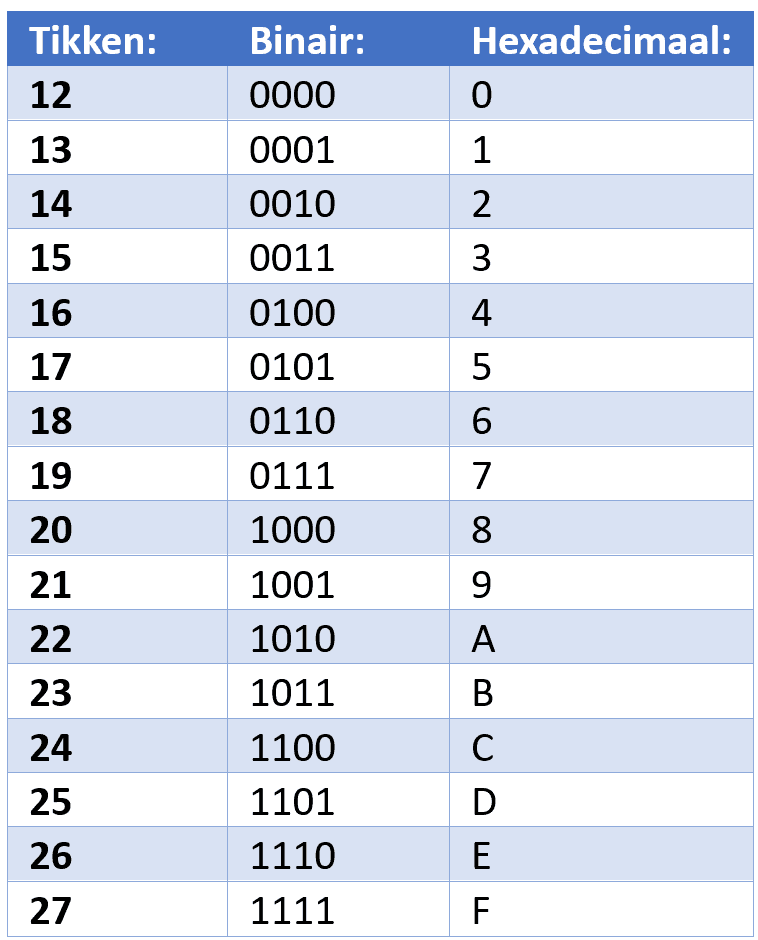

Each nibble in a SENT signal can have values from 0 to 15, depending on how many ticks it is 5 volts. The image below shows the structure of the SENT protocol.

'Nibble groups' are sent, numerically from 0000 to 1111 in binary format. Each nibble represents a value from 0 to a maximum of 15, and they are represented in binary as follows: 0000b to 1111b and hexadecimal from 0 to F. These digitized nibbles contain the sensor values and are sent to the ECU.

To send this nibbling information, 'ticks' or computer ticks are used. The clock tick indicates how quickly the data is being sent. In most cases the clock tick is 3 microseconds (3μs) up to a maximum of 90μs.

In the first case, this means that a new nibbling group is sent every 3 microseconds.

The message begins with a 56-tap sync/calibration pulse. For each of the two signals: signal 1 and signal 2, three nibbles are sent, resulting in a sequence of 2 * 12 bits of information. The CRC follows these signals

(Cyclic Redundancy Check) for checking, which allows the recipient to verify that the data received is correct.

Finally, a pause pulse is added to clearly mark the end of the message to the recipient.

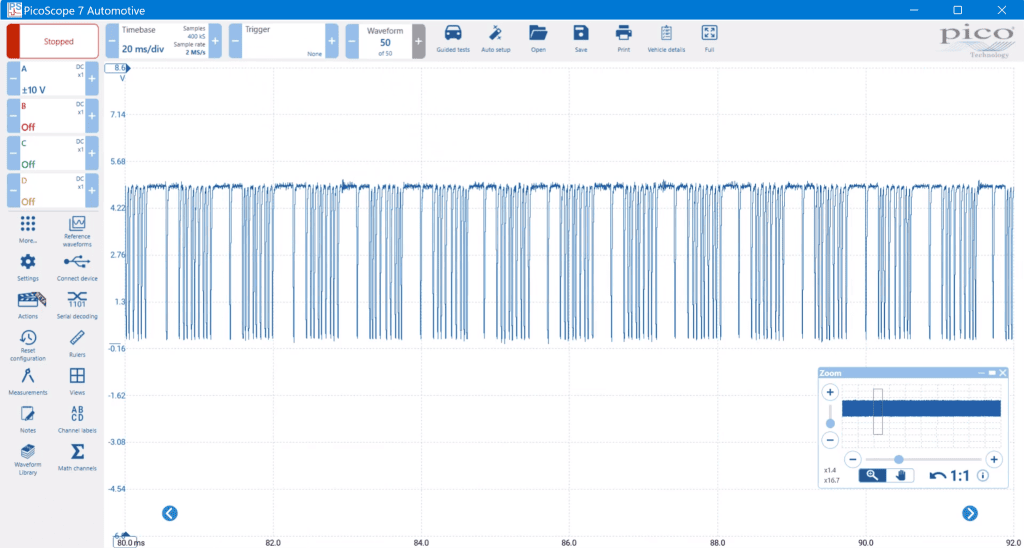

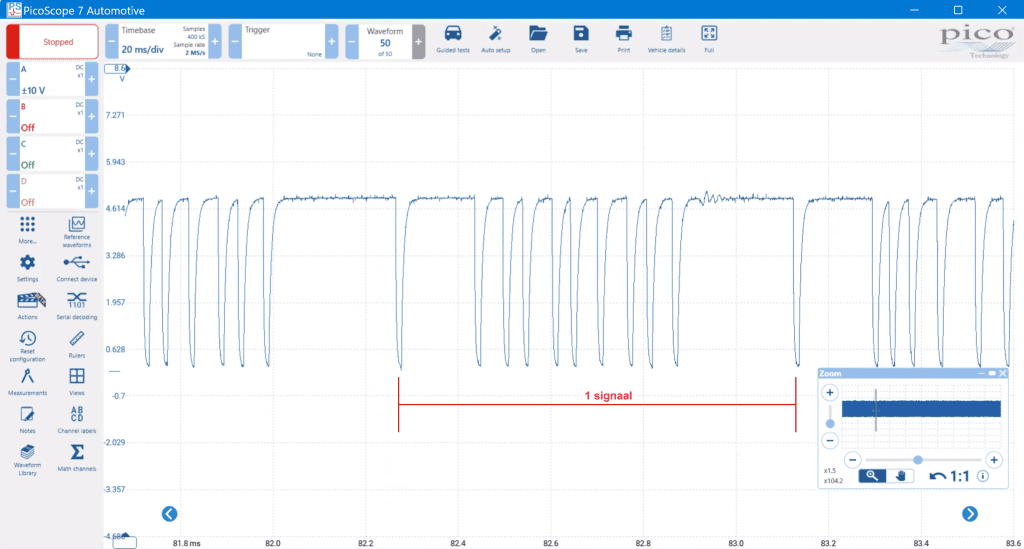

The scope images below (recorded with the PicoScope Automotive) show measurements of multiple messages (left) and a zoom in on one message (right). In the zoomed-in message, it is indicated in red where the signal starts and ends. When conditions change: the pressure and/or temperature increase, there will be a change in the number of ticks in one or more nibbles. The change in ticks will be visible in the scope image below in one or more voltages that vary between 0 and 5 volts. The pulses can become wider or narrower. The actual information can be decoded with the Picoscope software.

With an electrical diagnosis, we can use the Picoscope software to decode the message to study it, but in most cases we focus on checking a clean message flow without noise, and whether the supply voltage (5 volts) and ground of the sensor are in be in order.

Power supply and signal processing:

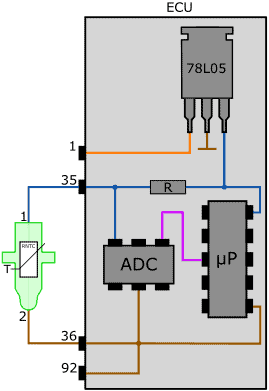

In the first paragraphs, we talked about whether or not a power supply voltage was used. In this section we discuss the main components in the ECU that are responsible for the power supply and signal processing of the respective sensor. The pin numbers of the in-depth diagrams are the same as in the previous paragraphs: pins 35 and 36 of the ECU are connected to pins 1 and 2 of the passive sensor, etc.

In the first image we see a NTC temperature sensor. The reference voltage (Uref) from pin 35 of the ECU is obtained from the voltage stabilizer 78L05. The voltage stabilizer supplies a voltage of 5 volts at an on-board voltage of 6 to 16 volts.

The resistor R (fixed resistance value) and RNTC (temperature dependent resistance) together form a series connection and also a voltage divider. The Analog-to-Digital Converter (ADC) measures the voltage between the two resistors (analog), converts it into a digital signal and sends it to the microprocessor (µP).

With a multimeter you can measure the voltage on pin 35 of the ECU or pin 1 of the sensor.

On the page about the temperature sensor In addition to some measurements with good signal transmission, the measurement techniques in the event of a fault in the wiring are shown.

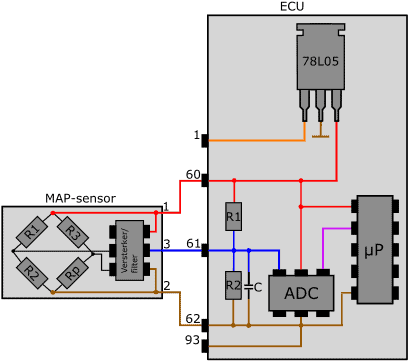

The second image shows the circuit of an active MAP sensor to display.

The stabilized supply voltage of 5 volts reaches the so-called “Wheatstone Bridge“, which includes a number of fixed (R1, R2, R3) and a variable resistor (Rp).

The resistance value of Rp depends on the pressure in the intake manifold. Here too we are dealing with a voltage divider. The resistance change causes a voltage change, so that the bridge is no longer in balance. The voltage difference created in Wheatstone's bridge is converted in the amplifier/filter into a voltage with a value between 0,5 and 4,5 volts. Digitization of the analog signal takes place in the analog-to-digital converter (ADC). The ADC sends the digital signal to the microprocessor.

The resolution of the ADC is in most cases 10 bits, divided over 1024 possible values. At a voltage of 5 volts, each step is approximately 5 mV.

The internal circuit of the ECU contains one or more passive and active sensors resistors included in the power and signal circuits. The resistance in the NTC circuit is also referred to as the “bias resistor” and serves for the voltage divider. The resistors R1 and R2 in the ECU circuit of the MAP sensor have the purpose of allowing a small current to flow from the plus to ground.

Without these resistors, a so-called “floating measurement” would occur if the signal wire was interrupted or if the plug of the sensor was removed. In those cases, the circuit with resistors causes the voltage on the ADC input to be pulled up to about 5 volts (minus the voltage across resistor R1). The ADC converts the analog voltage into the digital value 255 (decimal), i.e. FF (hexadecimal) and sends this to the microprocessor.

A very small current flows through resistor R1 (low Ohm). There is a small voltage drop of between 10 and 100 mV. It can happen that the applied voltage is a few tenths higher than 5 volts; A low-ohmic resistor is included between the ground connection of the voltage stabilizer 78L05 and the ground of the ECU (brown wire in the above diagram). The voltage drop across this resistor can be, for example, 0,1 volts. The voltage stabilizer sees its ground connection as actual 0 volts, so it raises the output voltage (the red wire) by 0,1 volts. In that case, the voltage sent to the plus of the sensor is not 5,0 but 5,1 volts.

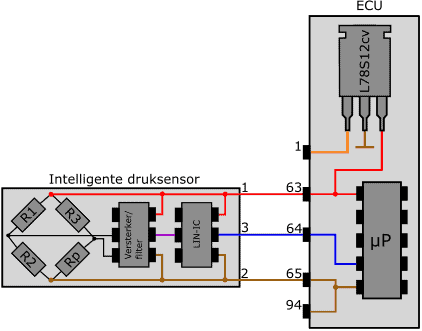

The intelligent sensor receives a voltage of 12 volts from the ECU. As with the active sensor, the intelligent sensor incorporates a Wheatstone bridge and an amplifier/filter. The analog voltage from the amplifier is sent to the LIN interface (LIN-IC).

The LIN interface generates a digital LIN bus signal. The signal varies between 12 volts (recessive) and about 0 volts (dominant). With this LIN bus signal, the sensor communicates with the other slaves (usually the sensors and actuators) and the master (the control unit).

There are branches to the master and other slaves on the wire between pin 3 of the sensor and pin 64 of the ECU.

For more information, see the page LIN bus.