Introduction:

Every gasoline engine has a throttle valve. The throttle valve controls the amount of air that enters the cylinder. Diesel engines also have a throttle valve, but it remains fully open while the engine is running because a diesel engine operates on an air surplus. The throttle valve in diesel engines only serves to smoothly shut down the engine; when the valve closes, the air supply is cut off, and the engine stops immediately. The fuel supply is also stopped. In a diesel engine, this is often referred to as a choke valve instead of a throttle valve. In fact, a throttle valve in a gasoline engine also functions as a choke valve, restricting air under all conditions except full load.

Subsequent chapters discussing monopoint and multipoint injection systems obviously pertain to gasoline engines.

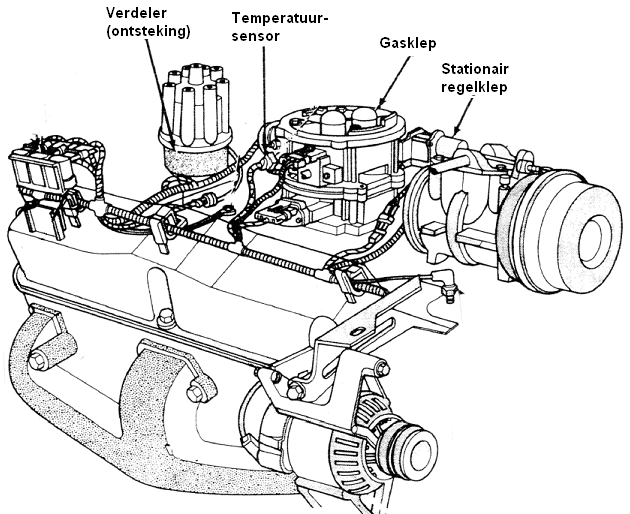

Throttle Valve in a Monopoint Injection System:

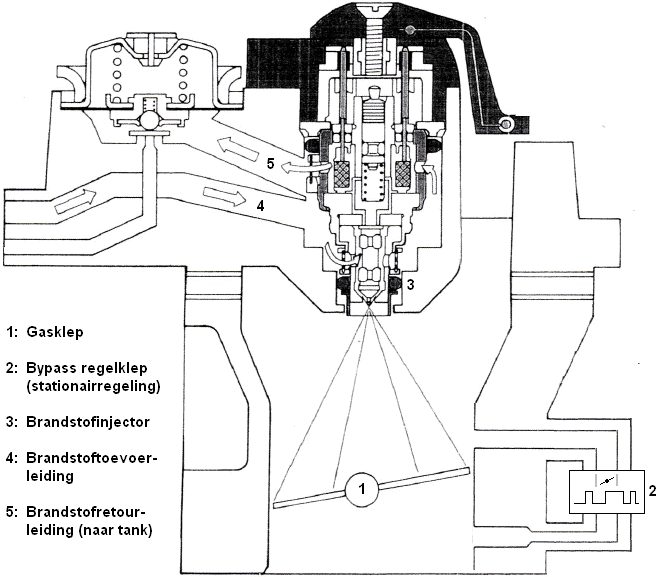

In engines with single-point injection (monopoint injection system), one injector is mounted on the throttle valve. This injector sprays fuel directly onto the throttle valve. This technology is old and is no longer used in new cars because of several disadvantages. As the injector sprays onto the throttle valve, the fuel mixes with the air there. The intake manifold is divided over four or more cylinders. The amount of fuel may not be exactly the same in all cylinders. For instance, cylinder 1 receives the most fuel in the air supply, while cylinder 4 receives much less. This makes the system unmanageable or hardly manageable. Thus, the application of monopoint is unsuitable to meet current environmental requirements.

Today, multiple injectors are used, each injecting the exact same amount of fuel per cylinder. The amount can even be regulated per cylinder. We call this the multipoint injection system.

Throttle Valve in a Multipoint Injection System:

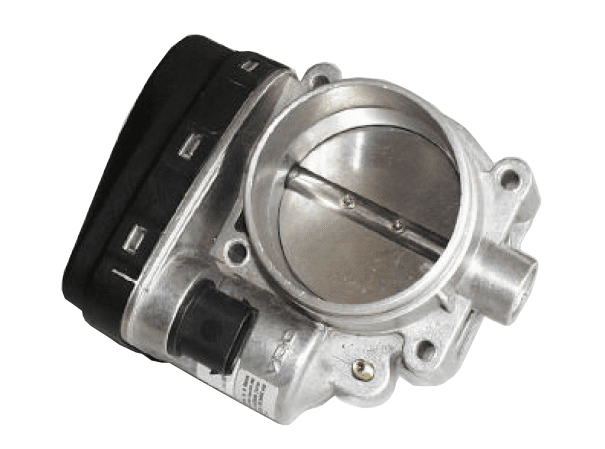

In engines with multi-point injection (multipoint injection system), the injectors for indirect injection are mounted in the intake manifold after the throttle valve. The injectors spray onto the engine’s intake valves. For direct injection, the injectors spray directly into the combustion chamber. In both indirect and directly injected engines, there is a throttle body mounted as illustrated below. Exceptions include engines with Valvetronic (BMW) and Multi-air (Fiat).a0The throttle body is installed between the intake manifold and the pipe with the mass airflow sensor. It can be electrically controlled using an electronic accelerator pedal (drive by wire) or with a throttle cable (Bowden cable).

The engine management systems used today employ a throttle position regulation. An actuator on the throttle valve allows its position to be changed. This can be for cruise control or idle control. Potentiometers measure the position of the throttle valve. The engine control unit (ECU) receives the readings from the potentiometers and can control the actuators to open or close the throttle more.

Idle Control:

To accelerate, the accelerator pedal is pressed. The throttle valve opens, allowing a larger amount of air to be drawn in. During deceleration or idling, the accelerator pedal is not operated; here, the throttle valve is closed. To allow air passage, an idle control is applied. The idle speed is kept as low as possible by the engine management system. The lower the idle speed, the lower the fuel consumption and engine wear. The idle speed must not be too low, as this can cause the engine to idle irregularly and may stall. The desired idle speed is not always the same. The temperature of the intake air, activated air conditioning, the position of the clutch pedal, or the automatic transmission selector lever affect idle control. Stabilizing the idle speed can be achieved in several ways:

- Filling rate control. Commonly used in combination with adjustment of the ignition timing.

- Altering mixture composition. This negatively influences exhaust emissions, and the control range is limited.

- Adjusting ignition timing. This also impacts emissions negatively but enables extremely fast control.

- Adjusting valve timing. Provides an additional control option on top of an existing filling rate control.

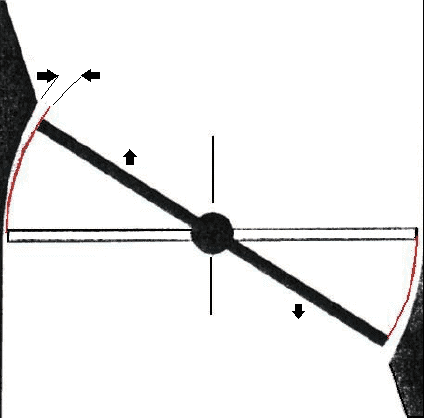

With filling rate control, a bypass valve is used that allows air to bypass the throttle valve or to adjust the throttle position.

Bypass Valve:

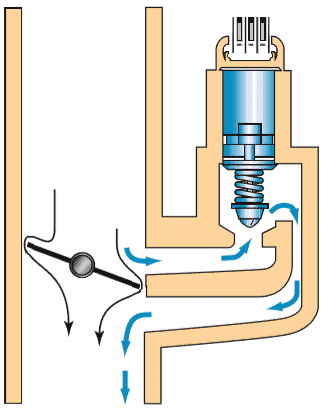

A bypass valve opens or closes the air supply outside of the throttle valve to stabilize idle speed. In the image below, a partially opened throttle valve is shown on the left. On the right side, an open bypass valve allows air to be drawn into the bypass channel through the engine. When the throttle valve opens further, the bypass valve will close. The bypass is only necessary when the throttle valve is closed. The engine management system determines how far the bypass valve must open. The throttle position sensor, indicating the opening angle of the throttle valve, provides the necessary information along with the air temperature sensor.

The commonly applied bypass is a pulse width modulated spring-loaded solenoid valve. The engine management system provides the solenoid coil with a PWM signal. By varying the duty cycle, the valve can be opened, closed, or positioned anywhere in between. The bypass valve may also be operated with a stepper motor.

Pulse Width Modulated Bypass Solenoid Valve:

The image shows two views of a PWM-controlled bypass valve. Judging by the three pins in the connector, this is often a version with two coils; one to open the valve and one to close it.

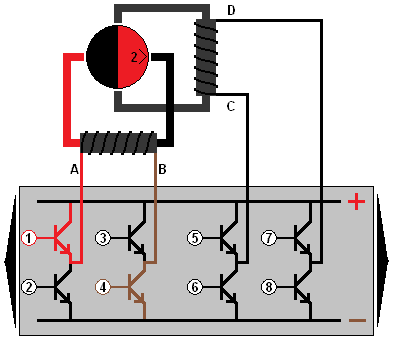

The diagram below shows the control method for the two coils. When the “EFI Main Relay” (relay for the engine management computer) is activated, the microprocessor is powered. Two transistors in the ECU are controlled.

The switching method allows the lower transistor to invert the PWM signal from the upper one. The PWM signals are mirrored. This is observable at ISC1 and ISC2 (the outputs of the ECU). The ECU varies the duty cycle for each coil. The difference in strength between the two magnetic fields determines the position of the valve. The frequency ranges between 100 and 250Hz.

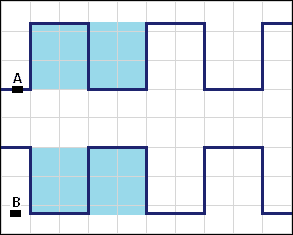

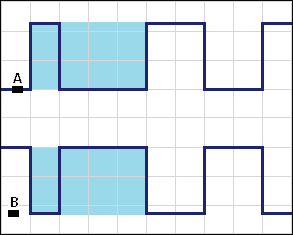

The duty cycle control can be measured with an oscilloscope. In the image below, the valve is half open (duty cycle 50%). On ISC1 and ISC2, the positive and negative pulses are equal.

Pulse Width Modulated Spring-loaded Bypass Solenoid Valve:

Aside from the actuator with two coils, it is also commonly executed with one coil. In that case, there are often two pins in the connector: for PWM control and a ground wire. A spring ensures the valve closes at rest, making the second coil unnecessary.

Bypass Equipped with Stepper Motor:

In addition to the PWM-controlled bypass valves, there are valves that are adjusted using a stepper motor. The ECU manages the coil control. Click here to go to the page about the stepper motor.

Throttle Body with Actuator:

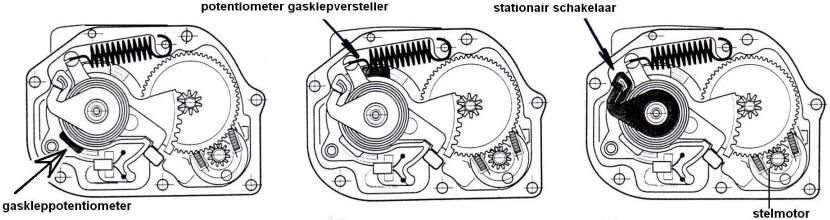

Modern engine management systems use throttle position regulation to stabilize idle speed. A separate bypass valve is not necessary. All components for throttle position regulation are contained within the housing. Two potentiometers register the throttle valve position throughout its rotation (middle of the image). Together with the idle switch, which records idling (left), the signals are sent to the ECU. Using a PWM signal, the DC motor in the throttle controls the throttle position. There is also the possibility of a stepper motor adjusting the throttle position.

The interior of the throttle body is adjusted so that the air gap increases linearly with the throttle rotation angle. This requires high precision. It’s important that after replacing or cleaning the throttle, its position is set to basic settings using diagnostic equipment.

Throttle Valve Control in Larger Engines:

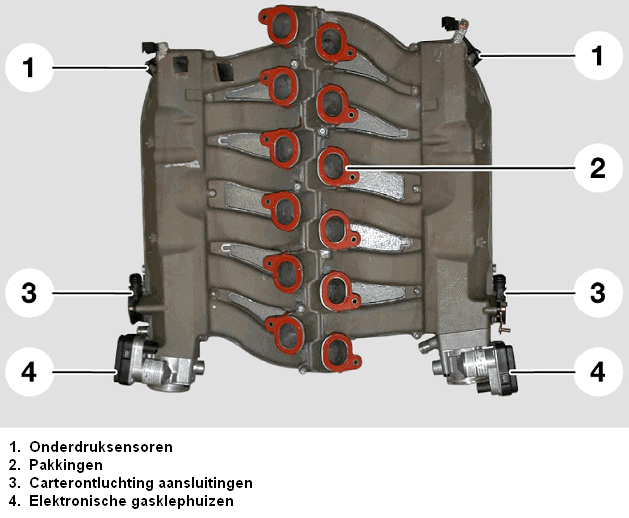

In large engines, like the BMW V12 engine (seen in the image below), the air supply through one throttle valve is insufficient. Under full load, the engine needs so much air that the diameter of a single throttle valve would be too small. Therefore, there are two throttle bodies installed. One for each cylinder bank. In this setup, there are two air filter housings, two mass airflow sensors, and two intake ducts.

Throttle Position Sensor:

Inside a throttle body, there is a throttle position sensor that transmits the position of the throttle valve to the ECU of the engine management system. The position of the throttle valve determines the amount of intake air, and consequently, the amount of fuel to be injected. Based on the throttle position, the ECU can adapt the idle control to operating conditions, such as a cold engine or when the air conditioning is on, where the idle speed needs to be slightly increased, and thus the throttle needs to open slightly further. Refer to the section on idle control for more details.

In the following diagram, we see an ECU and a potentiometer connected by three wires. The potentiometer has a mechanical connection to the throttle valve. A rotation of the throttle valve will result in a shift of the slider.

- Pin 3 supplies the potentiometer with a 5-volt power supply;

- The potentiometer is connected to the ground on pin 1;

- The signal from the potentiometer is sent to the ECU via pin 2: the slider (the arrow) is attached to this wire.

The position of the slider on the carbon track of the potentiometer determines the output voltage. When the slider is positioned far to the left, the output voltage is high: the current travels only a short distance over the resistance, absorbing less voltage. The further the slider moves to the right, the lower the signal voltage will be. The page: potentiometer explains the operation in further detail.

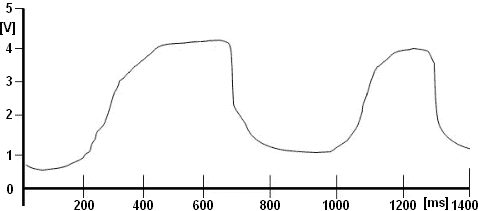

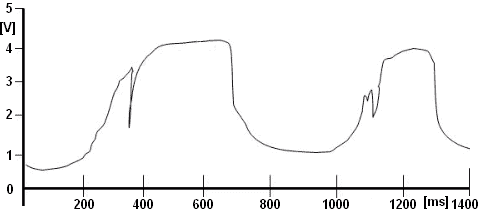

With a multimeter, you can measure the supply voltage relative to the ground. This should be a stabilized voltage of 5.0 volts. The signal voltage is better measured with an oscilloscope: disturbances can appear in the AM signal that are not visible with a multimeter measurement. The two drawings below show a correct signal (smooth lines) and a signal with interference, where the signal exhibits a significant voltage drop within a very short time frame.

In English literature, but sometimes also in Dutch, we often see the abbreviation “TPS” used. This stands for: “Throttle Position Sensor”, which is a translation of the Dutch “Gaskleppositiesensor”.

Electronic Accelerator Pedal (Throttle by Wire):

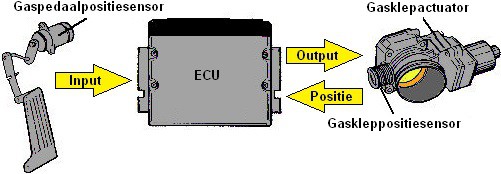

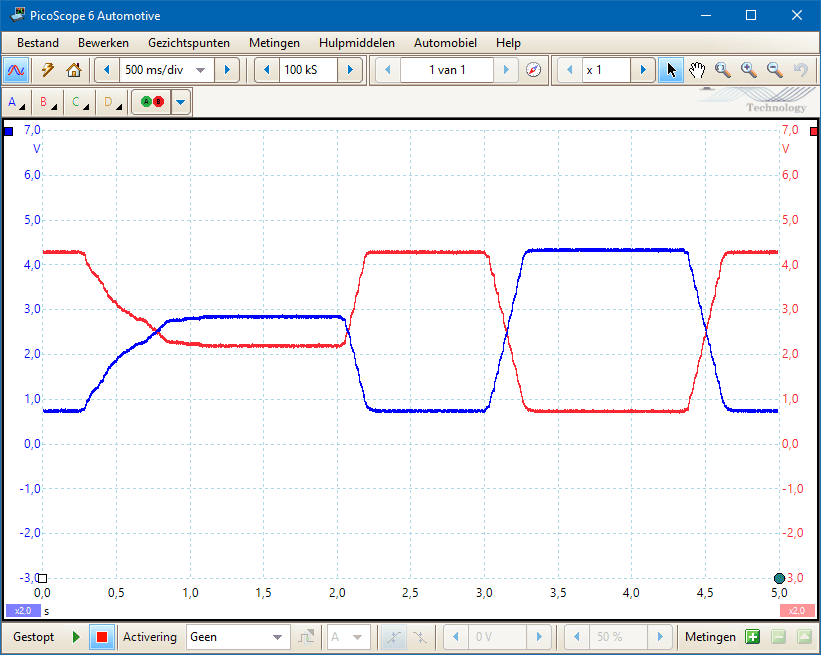

Today, throttle valves are electronically controlled: there is no (mechanical) cable between the accelerator pedal and the throttle valve. The position of the accelerator pedal is recorded by two position sensors and sent to the ECU of the engine management system. The ECU checks the plausibility of the signals by comparing them and controls the throttle actuator (actuator motor) to set the valve to a pre-determined position. This is referred to as “throttle by wire”, in Dutch: throttle control via wiring.

The accelerator pedal position sensors are mounted in the housing or on the top of the accelerator pedal. The signals from these sensors must be extremely precise and reliable: under no circumstances do we want a signal malfunction to cause unintended acceleration, or for the engine to hold back. To ensure reliability, manufacturers use two position sensors:

- Manufacturers may choose to transmit the signals from both sensors at different voltage levels. When the signal voltage of sensor 1 rises from 1.2 to 1.6 volts, the signal voltage of sensor 2 also rises by 400 mV, but from 2.2 to 2.6 volts;

- Another possibility is to mirror two identical signals: The oscilloscope image below shows this strategy. When the accelerator pedal is operated, the signal on channel A (blue) rises from 800 mV to 2.9 volts and the signal on channel B (red) falls from 4.3 to 2.2 volts. The amplitude signal progression (AM signal) is exactly the same, but mirrored.

If one of the two signals has a malfunction, such as the signal dropping off to ground or showing noise, a difference in both signals is detected. The ECU may then decide to go into limp mode: the accelerator pedal position is no longer reliable. In limp mode, there is limited power available, allowing you to drive to a safe spot on the road or possibly to the garage at reduced speed.

The throttle is opened and closed using a DC electric motor. The throttle actuator motor is controlled using an H-bridge. Like the accelerator pedal, the actuator motor is equipped with two potentiometers. The two images below show the throttle actuator motor (3) with two possibilities of the dual potentiometers:

- Potentiometers with sliders oriented upwards: both signals run parallel to each other but at different voltage levels;

- Potentiometers with sliders opposed to each other: signals are mirrored. When opening the throttle, if one signal rises, the other drops.

On the H-bridge page, the control methods of the electric motor are described. On the Potentiometer page, there is a detailed explanation of the operation and measurement of the position sensor.