Indicated Power (Pi)

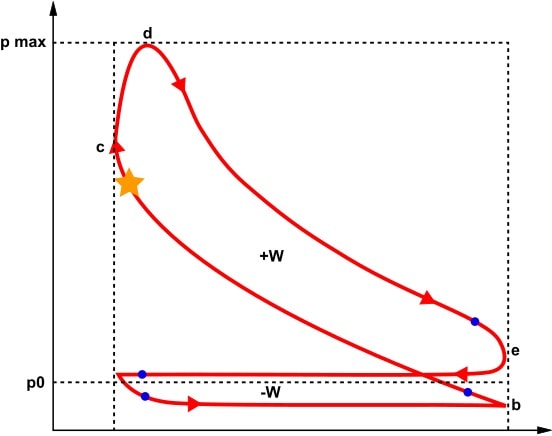

The power generated by combustion is called the indicated power. The English translation of “geïndiceerd vermogen” is Indicated Mean Effective Pressure, abbreviated as: IMEP. This internal power is determined from the indicator diagram.

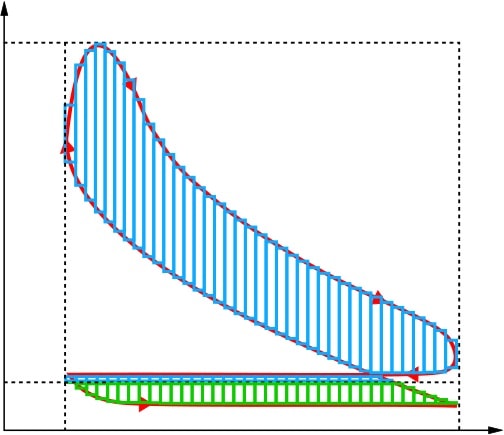

The following images show the same indicator diagram. The right one symbolizes calculating the areas: the positive (blue) and the negative area (green). When we have determined the relative area (positive minus negative), we talk about the mean effective pressure. In reality, this is calculated mathematically using integral calculations.

With the indicated power, we look at the average area in the indicator diagram. The power measured on the crankshaft will be lower due to mechanical losses.

Effective Power (Pe):

The effective power (in English: Brake Mean Effective Pressure, abbreviated as BMEP) is the power remaining after subtracting friction losses from the indicated power.

We will use this formula to calculate the power the engine delivers to its flywheel at the RPM where the torque is highest. The effective power will be lower than the indicated power due to friction losses occurring from the piston to the wheels, and auxiliary units like the oil pump, coolant pump, and alternator consuming power during engine operation. The formula is:

Where:

- Pe = total delivered power;

- pe = mean effective pressure;

- Vs = displacement volume;

- z = number of cylinders;

- i = 1 for two-stroke and 0.5 for four-stroke;

- n = RPM.

We will base the calculation on the following data:

- Mean effective piston pressure: 1400000 N/m² (= 14 bar);

- Displacement volume: 1.59 dm³ (0.3975 dm³ per cylinder);

- Number of cylinders: 4

- 4-stroke

- RPM: 3000 rpm.

The calculation again:

We input the data without considering scientific notation for now.

Important: we convert the displacement volume per cylinder from dm³ to m³ (divide by 1000, see: Calculating Volume). 0.3975 dm³ becomes: 0.0003975 m³.

This results in the engine delivering a power of 55.7 kW at the given RPM.

In the previous example, the mean effective pressure (pe) was given, and the delivered power (Pe) was asked. However, determining pe is not straightforward as no measuring equipment is available. When Pe is given and pe is unknown, we can reverse the formula to find it. We will do this in the next example.

Engine data:

- Maximum power: 147 kW at 5700 rpm;

- Bore: 82.5 mm;

- Stroke: 92.8 mm

We input the data into the formula:

We rearrange the formula, so the unknown is on the left side of the equals sign:

We convert the result to pressure in bar:

I.S.O. Power:

The I.S.O. power is determined on the engine test bench, where the manufacturer operates the engine under the following conditions:

- Ambient pressure (p) = 1 bar;

- Air temperature (T) = 300 K = 26.85 degrees Celsius;

- Relative humidity (RH) = 60%

- Coolant temperature entering the intercooler (Ti) = 300 K = 26.85 degrees Celsius;

- Lower heating value/ calorific value (H0) = 42 MJ/kg.

Related page: