Measuring Valve Guide Clearance:

Worn valve guides can lead to the following issues and defects:

- burnt valve faces;

- broken valve;

- wear of the rocker arm;

- increased oil consumption.

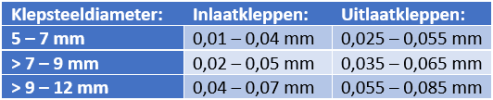

When the cylinder head is disassembled, we want to measure the clearance between the valve stem and the valve guides in case of the above complaints. Not all manufacturers describe the maximum permissible clearance in the service documents. In that case, we can refer to the reference values in the table below:

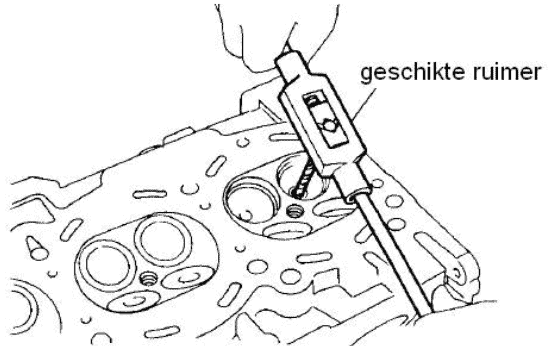

The following image shows the measurement where the valve guide clearance of the exhaust valve is measured. The dial indicator is mounted on a stand and has thus been given a fixed position. We position the needle of the dial indicator with a preload of at least 2 mm against the valve face of the valve, which is approximately 10 mm extended from the cylinder head.

Using moderate force, we try to move the valve back and forth towards the dial indicator. The pointer of the dial indicator will move back and forth over a certain area of the dial during the movement. The stroke made by the pointer indicates the clearance.

Replacing Valve Guides:

When we measure too much clearance between the valve guide and the valve stem, we consult the technical data of the respective engine to find out if the valve guides can and may be replaced. If this is not possible according to the factory specifications, a reputable refurbishment company often knows how to handle this. Otherwise, it would mean that the entire cylinder head would have to be replaced.

If it is possible to replace the valve guides, specialized equipment is required to remove the valve guides, ream the hole, and install new valve guides. In most cases, the cylinder head must be heated well above 100 degrees Celsius and the valve guides must be pressed into the holes.

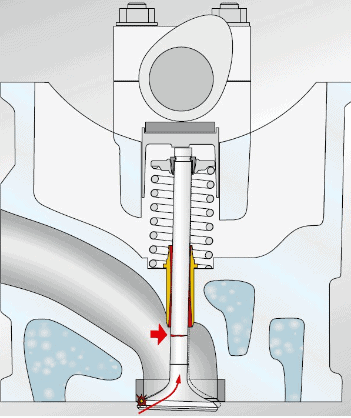

The two images below show the position of the valve guide in the cylinder head (left) and three different valve guides (right).