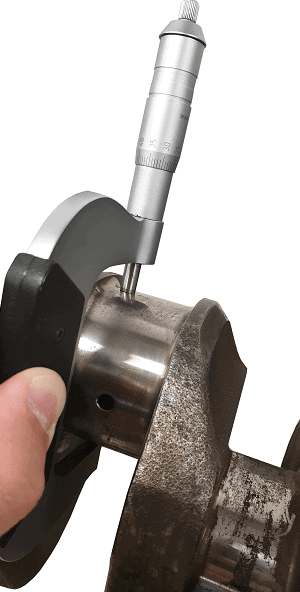

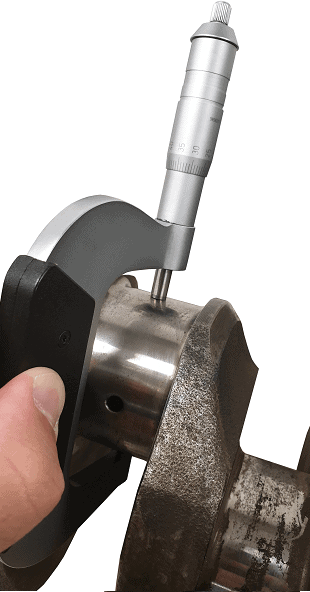

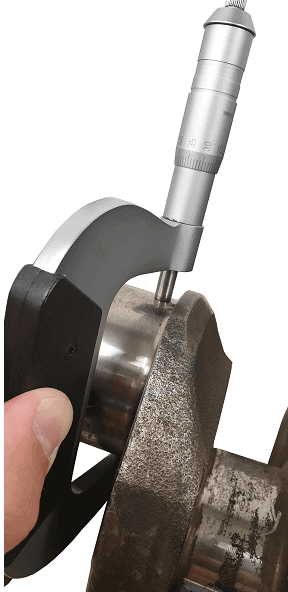

Measuring taper:

The crankshaft journal bearings can become tapered due to excessive wear. On a disassembled crankshaft, we can perform measurements on the main bearing journals and connecting rod bearing journals. Measurements can only be accurately carried out with a micrometer.

With three measurements, the taper of the bearing journals on a crankshaft can be measured. The diameters of the bearing journals should be almost identical in all three measurements. If one of the measurements shows a lower value (e.g., the diameter difference between the measurements on the left and right side is 0.2 mm), then the journal has become tapered due to wear.

The three images below show the measurements used to determine the taper. The micrometer cannot be read from this camera angle.

Measuring ovality / roundness:

The roundness of main bearing and connecting rod bearing journals is very precise. The bearing shells slide over them constantly through an oil film. When a journal is no longer perfectly round due to wear (in other words: oval), excessive axial bearing play or friction due to insufficient clearance can occur. In both cases, subsequent damage will occur over time.

With two measurements, the ovality of a journal can be measured. The measurements are taken 90 degrees apart at approximately the center of the journal. If both measurements yield the same result, the respective journal is not oval. An out-of-roundness of 0.02 mm already falls outside the tolerances: it is then necessary to grind the crankshaft. Always consult the manufacturer’s prescribed measurement values for these measurements.

Crankshaft grinding:

When measuring the taper and ovality of the crankshaft main bearing and connecting rod bearing journals, the crankshaft may be rejected based on the measurement results. In most cases, it is possible to have the crankshaft ground and possibly balanced by a reconditioning specialist. Since material is removed during grinding, oversized bearing shells must be installed. The two images below show the grinding process of a main bearing journal (left) and a connecting rod bearing journal (right).