Measuring the flatness of the cylinder head and engine block:

After disassembling a cylinder head, the flatness must be determined. There is a chance that the cylinder head is warped after the engine has overheated. If the warped cylinder head is reinstalled, there may be complaints regarding gasket leakage. In addition to the cylinder head, the rotating part of the engine should also be checked in the same manner. If we detect a significant deviation, there are usually machining options available to reinstall the cylinder head without issues. The requirements for measuring flatness are:

- clean measuring surface of both the cylinder head and engine block;

- steel straightedge;

- feeler gauges.

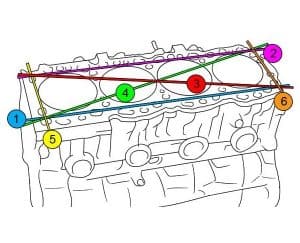

The following image shows a measurement on the surface between cylinders 2 and 3.

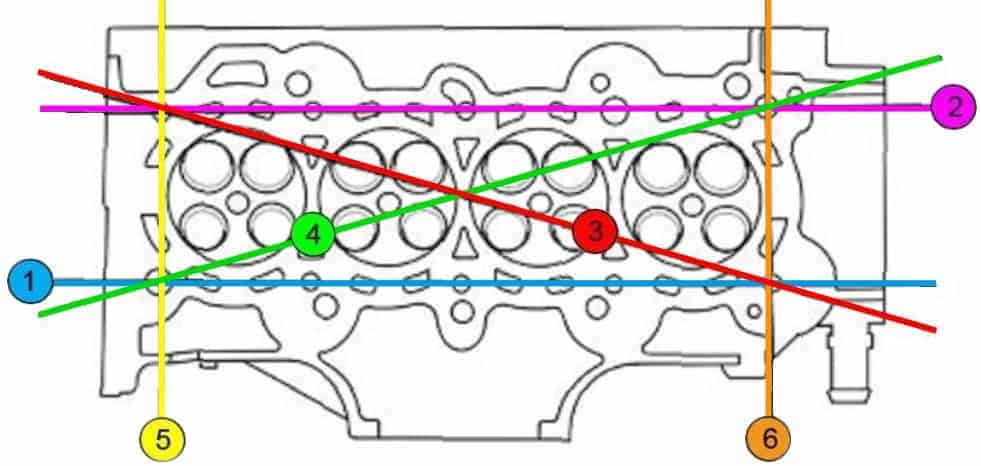

To determine flatness, a total of six measurements must be taken on the engine block and the cylinder head. The two images below show the positions in which the steel straightedge should be held. Once we have placed the steel straightedge in a position, we need to apply the feeler gauge approximately halfway along the length between the engine / head and the steel straightedge.

The maximum allowable gap between the engine / head and the steel straightedge should not exceed 0.05 mm (if the manufacturer prescribes a different dimension). If a feeler gauge of 0.1 mm can be inserted between the engine or head and the steel straightedge, we can assume deformation (a warped object).

If the deviation is very slight but just outside the tolerances, the cylinder head can be resurfaced at a reconditioning company. In this process, the machine removes material from the head until it is straight. With large deviations and thus coarse machining, this results in a smaller compression space. A thicker gasket compensates for this difference.

Related pages: