Introduction:

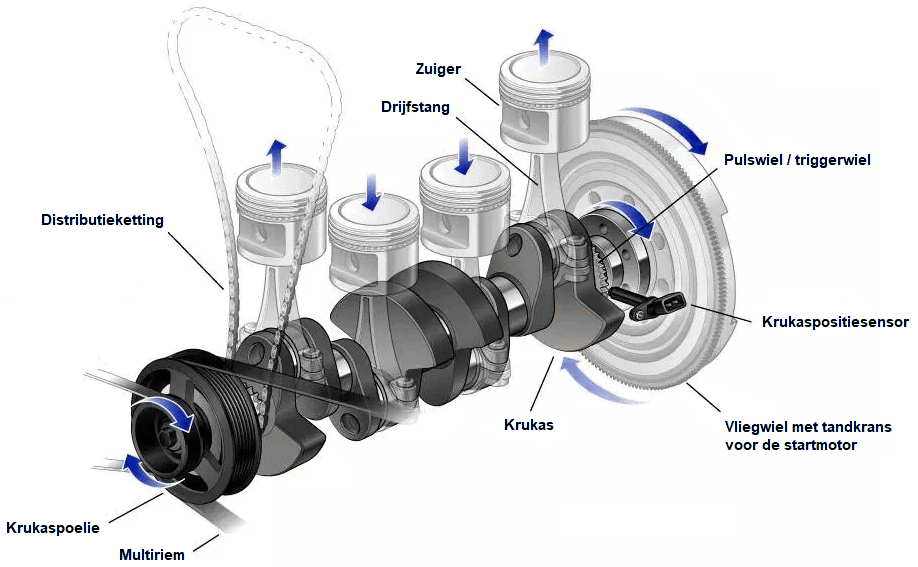

The crankshaft position sensor (also known as the TDC sensor or engine speed sensor) is usually mounted at the bottom of the engine block near the flywheel. When the engine is running, the crankshaft position sensor reads the teeth or magnets of the reluctor wheel that move past the sensor element. The crankshaft position sensor indicates a change in the magnetic field between the sensor and the reluctor wheel, resulting in a change in signal voltage (inductive or Hall). The rate at which these pulses follow each other indicates the RPM. At a certain point, there are one or two missing teeth on the reluctor wheel. The resulting signal is an indication for the engine control unit of the position of the pistons. This helps the engine management system determine, among other things, the injection timing and ignition timing. The crankshaft RPM is also sent to the tachometer in the instrument panel.

Positioning of the sensor and the reluctor wheel:

The reluctor wheel (also called the trigger wheel, reference wheel, or reluctor wheel) can be positioned in different places in or on the engine:

- externally on the crankshaft pulley: in older engines, we see that the crankshaft pulley, driven by the V-belt or multi-belt, is equipped with teeth. In modern engines, we no longer find this external reluctor wheel form;

- internally via machined teeth on the crankshaft: the reluctor wheel is positioned on the crankshaft on the inside of the crankshaft flange and is visible when the oil pan is removed;

- externally at the rear crankshaft seal: on the outside of the engine block, between the outside of the crankshaft flange and the flywheel, a toothed ring or magnet ring is installed. This can be accessed when the flywheel is removed.

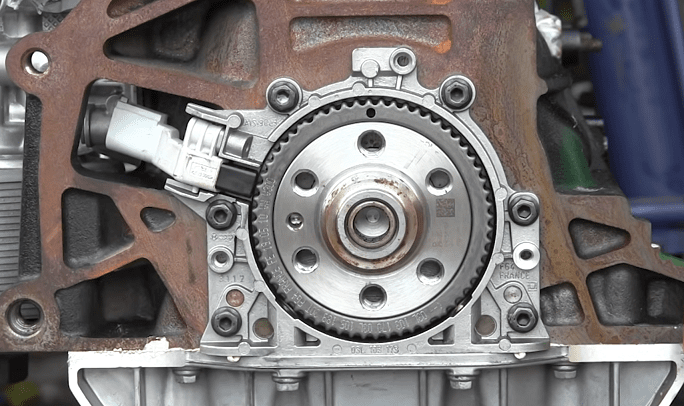

The crankshaft sensor is directed towards the reluctor wheel. In modern engines, the crankshaft sensor is often located at the side of the engine near the flywheel. The images below show three different installation locations of the crankshaft position sensor and reluctor wheel: teeth on the crankshaft inside the flange, and a magnet ring and toothed ring on the outside of the flange.

The above images show reluctor wheels with crankshaft position sensors used in VAG and BMW applications. The version often used in VAG applications consists of a cassette in which the toothed reluctor wheel also contains the housing of the crankshaft seal. The BMW magnet ring slides over the crankshaft flange. When replacing the flywheel, care must be taken not to let this magnet ring fall out. It is not uncommon for the engine to fail to start after replacing the clutch, including the flywheel, because the magnet ring was not reinstalled.

The missing tooth in the reluctor wheel:

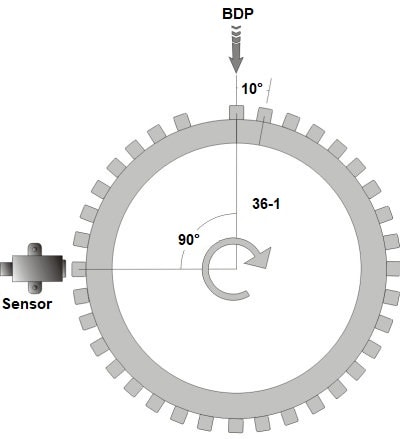

The crankshaft position sensor measures the teeth on the reference wheel, which is mounted on the crankshaft. The crankshaft position sensor “counts” the teeth that pass by and “detects” that there is a missing tooth in each revolution. Based on this missing tooth, the engine management system knows the position of the crankshaft, and therefore the height of the piston during the compression stroke in the cylinder.

The missing tooth is placed at the point where the piston of cylinder 1 is between 90 and 120 degrees before TDC. Therefore, the term “TDC sensor” is incorrect: the sensor does not measure the point when the piston is at TDC but rather the position where the piston is moving towards TDC.

Many engines are equipped with a 36-1 or a 60-2 reluctor wheel. In this example, we discuss the 36-1 reluctor wheel. This reluctor wheel has 36 teeth, one of which is removed. During each crankshaft rotation (360°), 36 (minus the missing) teeth pass by. This means every 10° one tooth passes the sensor.

In the illustration, we see that the missing tooth is almost at the top. In this position, the engine is at TDC. The direction of rotation is clockwise, so 90° earlier the missing tooth passed the sensor. This position is the reference point. In this 90° rotation, the piston of cylinder 1 moved from BDC to TDC.

When the missing tooth passed the sensor, the sensor translated this into a change in the crankshaft signal, and this served as the recognition point (reference point) for the engine management system to start injecting and/or igniting after a number of teeth later.

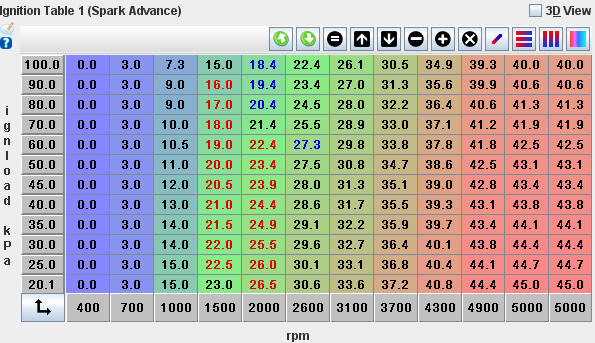

When increasing the engine speed or load, we refer to this as “pre-injection” or “advanced ignition timing“. Using the reference point at 90 or 120° before TDC makes this possible. Example regarding ignition timing:

- At low RPM and low load (1000 rpm at 25 kPa), the ignition advance is 15°. This corresponds to one and a half teeth before TDC;

- At increased RPM and load (3100 rpm at 60 kPa), the ignition advance is nearly 30°. This corresponds to three teeth before TDC.

At the moment when, in the last situation, ignition must occur three teeth before TDC, the engine management system has time to control the ignition coil between the 9 teeth (90°) from the reference point and three teeth (30°) from the desired ignition timing, so that the ignition is initiated before the piston reaches TDC.

A crankshaft position sensor sends a signal from which the engine management system can infer that the piston of cylinder 1 is at the position 90° or 120° before TDC. What is not known is whether the piston is in the compression stroke or the exhaust stroke.

- An engine with only a crankshaft position sensor is equipped with a DIS coil, where on each crankshaft rotation all spark plugs fire, resulting in a “wasted spark” during the exhaust stroke;

- For individual control of coil-on-plug ignitions and injectors, a camshaft sensor is required. From the camshaft sensor’s information, the engine management system can determine that cylinder 1 is in the compression stroke, not the exhaust stroke.

With the combination of the crankshaft and camshaft sensors, the RPM and management of the injection and ignition system per cylinder can be realized.

Operation of the crankshaft position sensor:

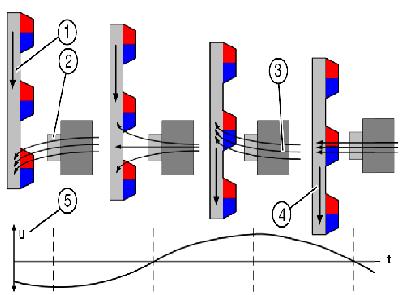

In the bottom left image, you can see the magnetic field lines that are generated as a tooth of the crankshaft moves past the magnet of the crankshaft position sensor. In the bottom right image, you can see the crankshaft signal. With each missing tooth on the crankshaft, there is an increased width and amplitude of the signal. The increased width in the signal is recognized by the engine management system as a reference point, indicating that the piston is at 90° or 120° ahead of TDC.

Electrical diagrams of the crankshaft position sensor:

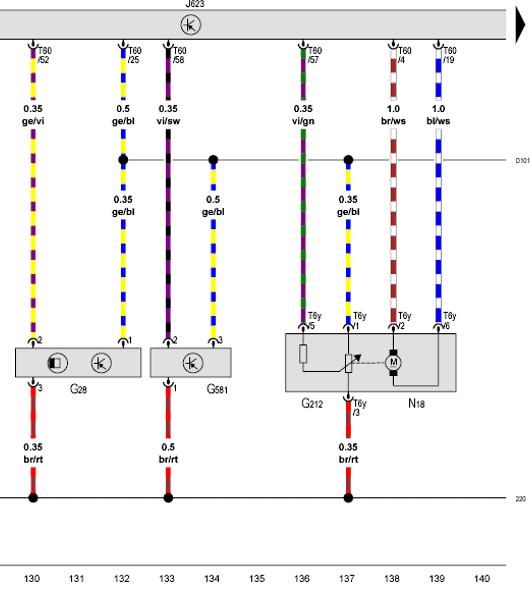

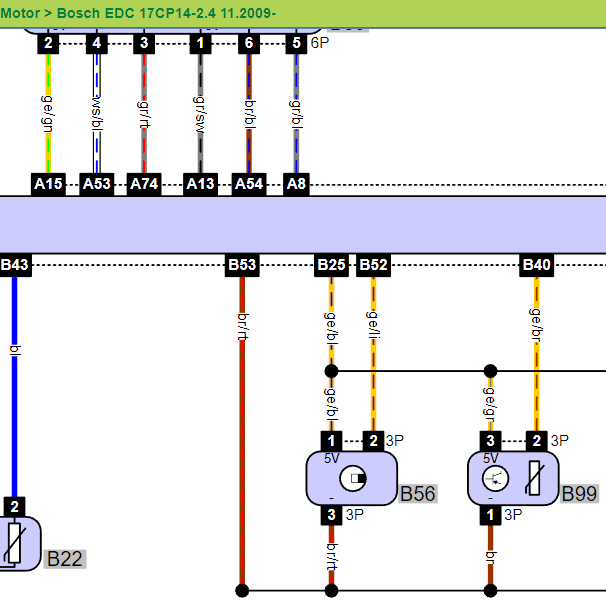

To measure the crankshaft position sensor, we first consult the electrical diagrams. The diagrams below are from the sensor of the same engine (VW Golf VI).

- In the VAG diagram, the crankshaft position sensor has the component code G28 and in HGS data B56;

- The VAG diagrams have coding T60 on the ECU with the pin number of the connector (T60/25) and HGS data uses the letter B (B25). Elsewhere in the diagram, it is stated that connector B is the 60-pin connector on the ECU.

From pin 25 on the ECU, a supply voltage of 5 volts is sent to the crankshaft position sensor, fuel pressure sensor, EGR valve, throttle valve, and position sensor of the turbo adjustment. Not all components are shown above. Pin 25 is therefore used for power supply. Pin 53 is for grounding (as seen in the HGS data diagram) and pin 52 for the signal of the crankshaft position sensor. We can measure directly on pin 52 in the ECU connector, or connect a breakout box to safely and clearly measure connection 52 of the breakout box.

Measuring signals with the oscilloscope:

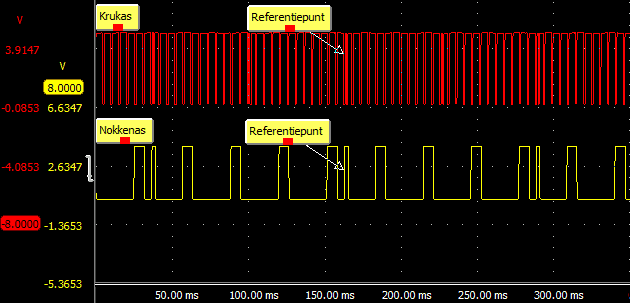

The crankshaft signal can be displayed with a dual-channel measurement in relation to the camshaft signal. These signals can determine whether the timing of the distribution is still correct or if the camshaft signal, for instance, is lagging behind the crankshaft signal due to a stretched timing chain. The image below shows a measurement of a crankshaft signal (channel A, blue) in relation to a camshaft signal (channel B, red).

In the signals from the crankshaft and camshaft sensors, we can recognize the following points:

- Every camshaft rotation (recognition points: the two narrow blocks), four missing crankshaft teeth have passed;

- The crankshaft rotates twice for each camshaft rotation (ratio 2:1), which means that every half rotation of the crankshaft, one missing tooth passes the sensor.

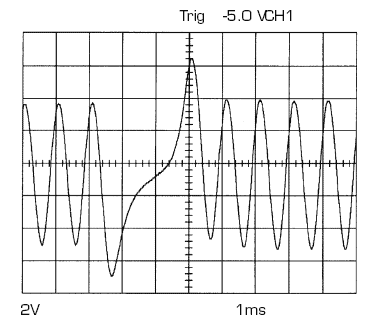

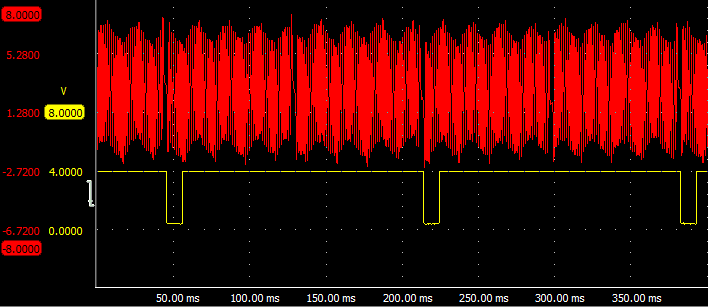

The engine in this example (VW Golf VI) is equipped with a toothed reluctor wheel with one missing tooth every 180 degrees (half revolution). This reluctor wheel is shown in the image of the paragraph “Positioning of the sensor and the reluctor wheel”. If you look closely, you can recognize the missing teeth in this image. When the engine’s RPM increases, the signal frequency also increases. The pulses then come closer together. The amplitude (the height of the voltage) remains constant. A reading on the same engine with increased RPM is shown in the scope image below:

In the case of suspected issues related to timing, reference points in the crankshaft and camshaft signals can be compared with a sample signal or with another engine that has no issues.

By marking two points, the difference in the number of teeth in the measured signal can be compared with the sample signal. If, in the measured signal, the crankshaft signal runs ahead of the camshaft signal (the reference point of the crankshaft shifts to the left), then it is possible that the timing chain is stretched.

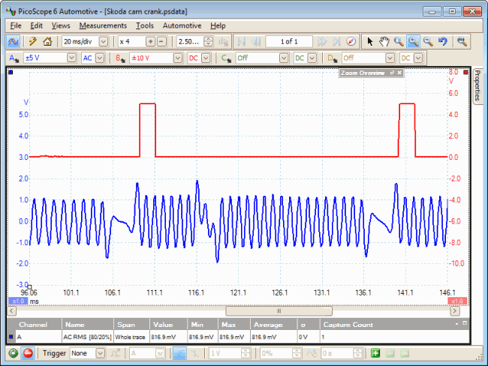

The above crankshaft signal is from a Hall sensor. An engine may also be equipped with an inductive sensor. An example of this can be seen in the measurement below. With an inductive sensor, at higher RPMs, not only does the frequency increase (the pulses get closer together), but the amplitude also increases. The frequency is important for the ECU to determine RPM. The missing tooth is clearly visible in this signal. The yellow line (from the camshaft sensor) provides a pulse after every second crankshaft signal. These signals can also be compared with each other.

For the inductive crankshaft signal as well, a reference point can be chosen, for example:

- the camshaft signal drops to 0 volts;

- this happens two (crankshaft) teeth after the missing tooth.

For a sample signal, one checks if two teeth are also present. If three teeth are present, there is again a deviation.

Possible malfunctions in the signal of the crankshaft sensor:

The crankshaft sensor may fail to output a signal. The engine management system does not receive an RPM signal, preventing the engine from starting. The camshaft signal may still be detected, allowing the engine to eventually start after extensive cranking, relying solely on the camshaft signal.

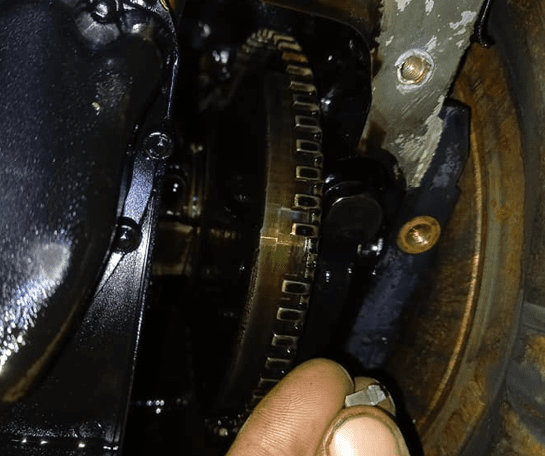

If the reluctor wheel is damaged, the engine management system may incorrectly recognize the damage as a missing tooth. The damage causes an anomaly in the amplitude of the alternating voltage output by the crankshaft sensor. An example is shown in the images below.

In the scope image, we see the characteristic waveform of the missing tooth twice (left, relative to the camshaft pulse). To the right of the camshaft pulse, we see an interference in the waveform. The engine management system reads this interference and may inject and ignite at the wrong times. When the engine management system compares the crankshaft signal with the camshaft signal, an error may be detected, and a DTC (diagnostic trouble code) related to the crankshaft signal may be stored. In this case, the crankshaft position sensor might be wrongly replaced.

The damaged tooth on the reluctor wheel might have been caused by engine work, where an attempt was made to block the crankshaft between the teeth of the reluctor wheel with a screwdriver instead of using the starter ring on the flywheel.