Operation of the Torque Converter:

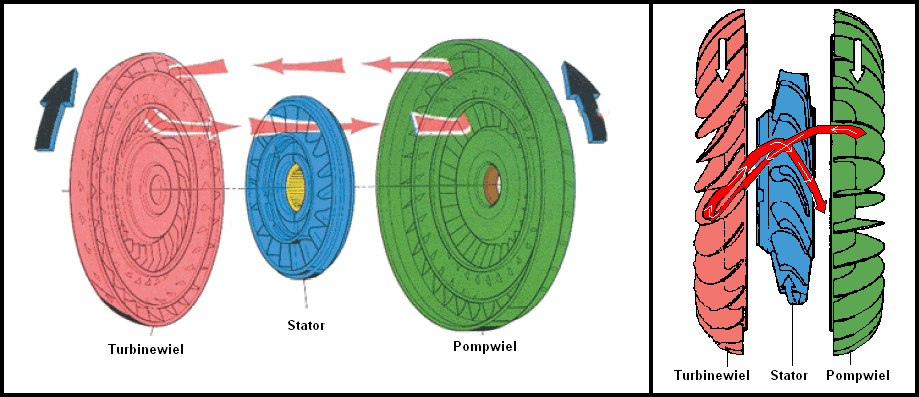

The torque converter is mounted between the engine and the automatic transmission and consists of 3 basic components; the pump wheel, the stator, and the turbine wheel. In a torque converter, the force exerted by the engine is transmitted through a fluid flow to the driven wheels. The pump wheel starts rotating. Due to centrifugal force, the fluid is flung outward. The fluid flows along the curved blades of the turbine wheel. The aim is that when the pressure increases, that is when more oil is pumped into the blades of the turbine wheel, the turbine will start to rotate.

When the engine speed is low, the centrifugal force of the fluid will still be too low to make the turbine wheel rotate. As the engine speed increases, the centrifugal force will become so great that the turbine wheel is carried along and the vehicle will start to move. The speed of the turbine wheel will increase until it almost reaches the speed of the engine. The pump speed and the turbine speed will never become completely equal under normal driving conditions because there are always certain losses, such as when the oil collides with the sides of the blades. There is always a certain amount of slip. This is also why cars with automatic transmissions always consume a little more fuel than cars with manual transmissions.

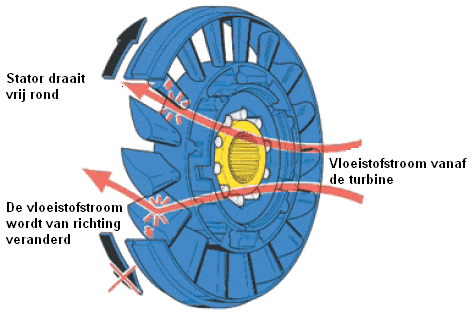

The stator is a ring-shaped component that rotates with the speed of the turbine. The stator ensures that the turbine is driven more powerfully. The stator has a freewheel function and can only rotate in one direction. The oil that flows back from the turbine can thus set against the stator, creating even more pressure in the turbine (see the illustration).