Introduction:

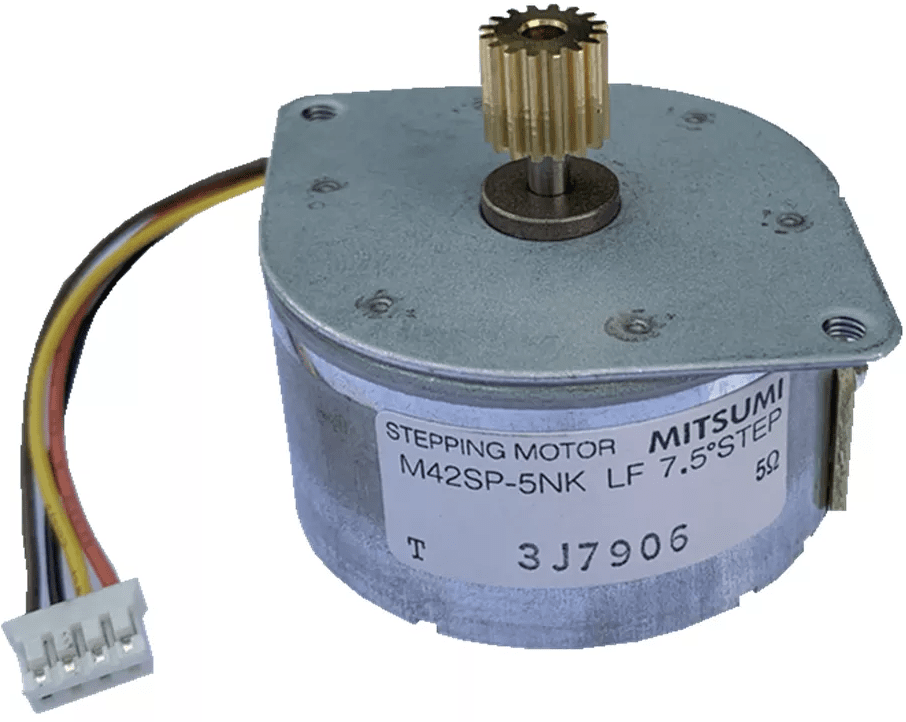

A stepper motor, as the name suggests, can be set in multiple steps. The number of steps can vary. Depending on the application, the stepper motor can adjust from 4 to 200 steps per rotation, which can result in a controlled rotation of 0.8° rotor rotation. ;

The angle of rotation in a stepper motor is very precisely determined. The stepper motor is essentially a synchronous DC motor without brushes because the components and control methods have many similarities, but it distinguishes itself from this direct current motor by the following characteristics:

- A stepper motor has a relatively high torque at low speeds and can start up very quickly from a standstill;

- The movement of a stepper motor is slow and very precise. The DC motor is used to spin quickly for long periods;

- The rotation speed and position of the stepper motor are controlled by a control signal from the control unit. Therefore, no position sensor or other form of feedback is required;

- A stepper motor produces more noise and causes more vibrations compared to a brushless DC motor.

The stepper motor is used in many areas of the car to enable a controlled electric movement of components. Below are three applications where the stepper motor is found, namely for idle control, the needles in the instrument cluster, and the heater flaps for ventilation control.

Stepper Motor for Idle Control:

The throttle valve of a gasoline engine is closed when at rest. To allow the engine to idle, a small opening is desired. The passage must also be adjustable because temperature and load (e.g., when consumers such as the air conditioning compressor are engaged) affect the required amount of intake air.

In modern engines, the position of the throttle valve is precisely controlled. We also find systems where the throttle valve is completely closed, and air bypass regulation directs air around the throttle. This bypass can be realized through a PWM-controlled DC motor or a stepper motor. See the page about the throttle for more information.

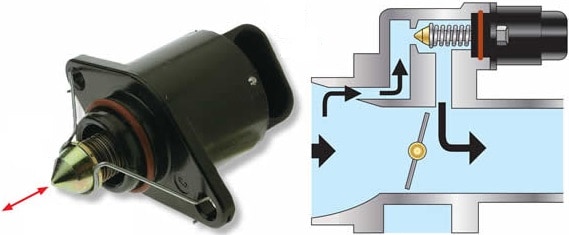

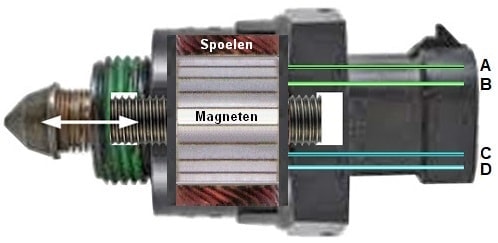

The three images below are of a stepper motor serving as an idle controller. The opening of the bypass is controlled by the shaft with the conical end. Rotating the armature in the stepper motor results in a rotation of the worm gear.

- Turning counterclockwise: worm gear rotates inward (large opening in the bypass);

- Turning clockwise: worm gear rotates outward (small opening in the bypass).

Instrument Cluster:

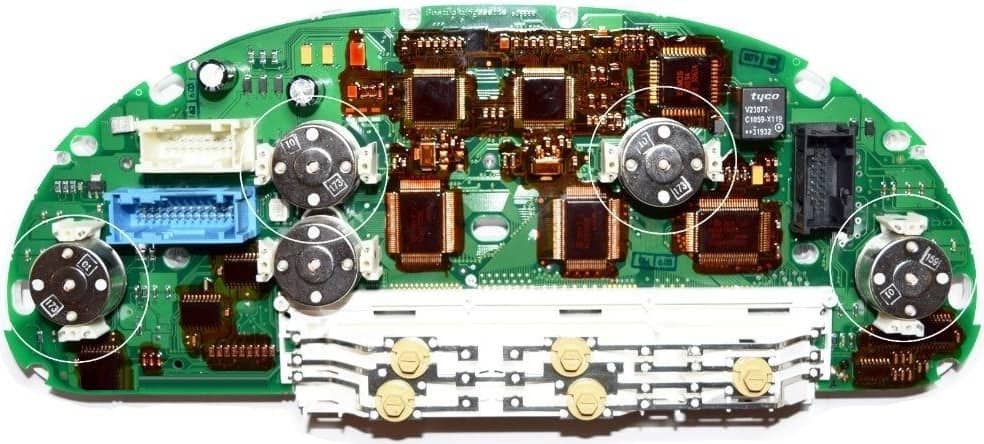

The instrument cluster often features multiple stepper motors for the fuel gauge, speedometer, tachometer, engine temperature, and in the example below, also the consumption gauge under the tachometer. Below is depicted the instrument cluster of a BMW.

On the back (inside) of the instrument cluster, we find the five stepper motors with black housing. On the right, we see the respective stepper motor without housing. Here the two coils and the four connections (two left, two right) are clearly visible, by which we can recognize the bipolar stepper motor. The stepper motor can adjust the pointer needles in small steps. The command to adjust comes from the ECU in the instrument panel.

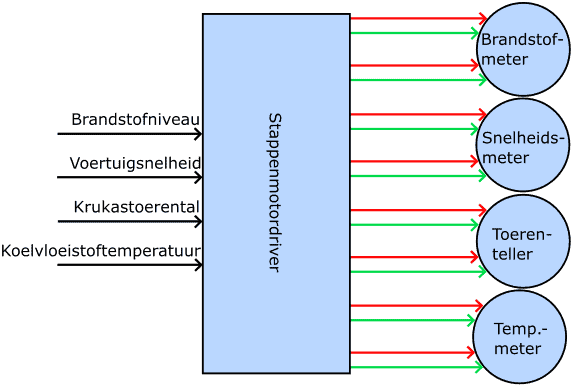

The following diagram shows the inputs and outputs of the stepper motor driver. This is the IC in the instrument cluster that translates incoming information into an output for the stepper motor:

- fuel level in the tank (fuel float);

- vehicle speed (pulse generator in transmission or ABS sensors);

- engine speed (crankshaft position sensor);

- temperature (coolant temperature sensor).

In the block diagram, the red and green arrows represent the connections (A through D) to the coils in the stepper motor.

Air Vent Flaps in the Heater Housing:

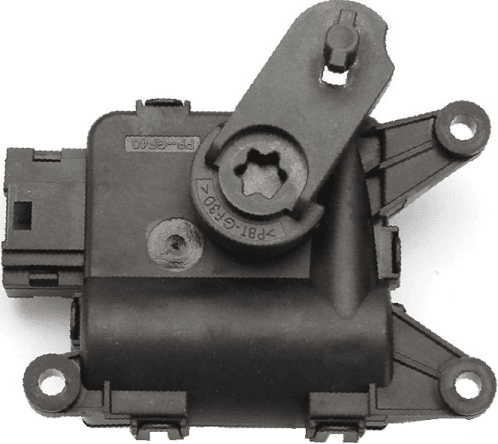

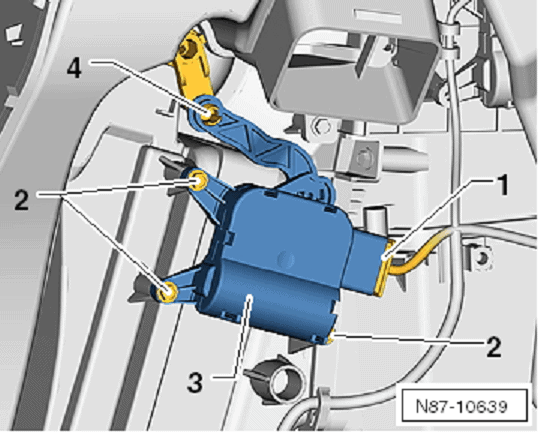

Stepper motors are often found in the electronically controlled air ventilation flaps in the heater housing. The images below show a photo of an air temperature flap (left) and an illustration of the installation position (right). The stepper motor operates the flap through the mechanism, wherein number 4 in the illustration indicates the pivot point. In the event of improper functioning of the stepper motor or after replacement, the start and end positions must be made known to the ECU. With diagnostic equipment, we can program the flap stops so the ECU knows when the flap is fully open or closed, allowing it to determine how long to control the stepper motor to partially open the flap.

Permanent Magnet Stepper Motor (PM type):

This type of stepper motor has a rotor with a permanent magnet. The advantage of this stepper motor is its simple construction and therefore a low cost. Below is information about the operation of this stepper motor.

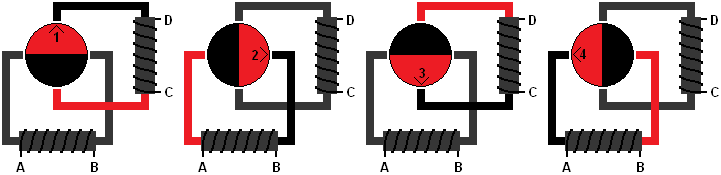

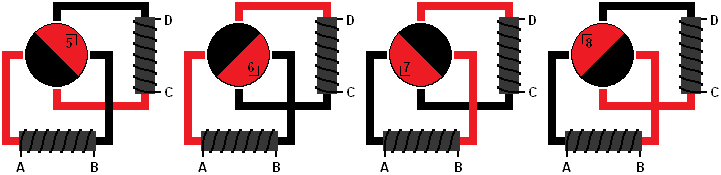

The rotor of the stepper motor can make a full rotation with multiple intermediate steps. In the example in the four images below, four intermediate steps per rotation are shown. The rotor can thus be stopped every 90 degrees. The left stepper motor is in position 1, with the north pole of the rotor at the top and the south pole at the bottom. To move the rotor 90 degrees clockwise, the current from the coil with connections C and D is interrupted, and the other coil is energized. This is seen in the second stepper motor. The left pole shoe turns red (the north pole), and the right turns black (the south pole). As a result, the rotor will be in position 2.

For positions 3 and 4, this works the same way; the coil between C and D is energized for position 3, only here the current runs in the opposite direction as in position 1. The upper pole shoe is now the north pole and the lower is the south pole. The rotor will now be in position 3. For position 4, the lower coil is energized again, and the rotor will rotate to position 4.

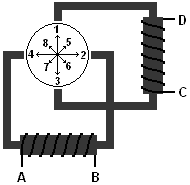

The four-position stepper motor can be stopped every 90 degrees. If this is insufficient for the application the stepper motor is used for, it can also be set in eight steps. This is possible with the same stepper motor, only in these intermediate steps both coils will be energized simultaneously.

In the image below, these intermediate steps are visible. These are steps 5 through 8. As you can see, step 5 is between steps 1 and 2. The same applies to step 6 (between steps 2 and 3) etc. In these intermediate steps, current flows through both coils.

When the rotor is turned to step 5, there is current from A to B in the lower coil and from C to D in the upper coil. There are now two north poles (the red pole shoes) and two south poles (the black pole shoes). The rotor will be in position 5.

To rotate the rotor another 45 degrees (to position 2), the diagram of the four-position stepper motor applies again. The lower coil will be energized again to allow current to flow from A to B.

If the stepper motor is then rotated another 45 degrees (to position 6), the above image applies again, where both coils are energized.

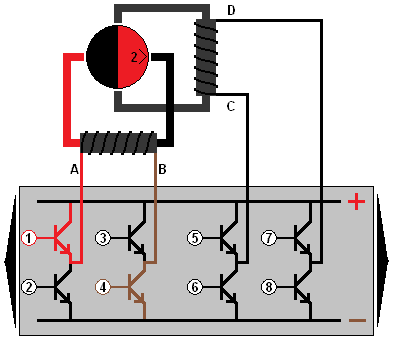

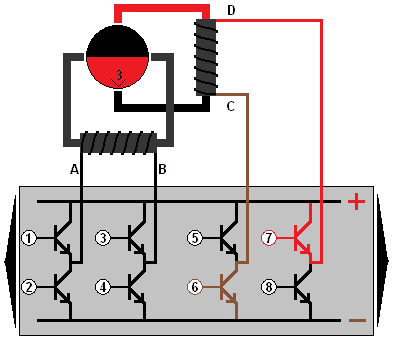

The stepper motor is always controlled by a control device. The transistors in the driver IC of the control device provide the supply and discharge of current to the pole shoes. The control device contains eight transistors. By controlling these eight transistors in the correct way, the stepper motor will rotate a full turn in four or eight steps. The rotation can occur in two directions; counterclockwise and clockwise. The control device ensures that the correct transistors are brought into conduction.

In the image, we see a stepper motor controlled by a control device. Transistors 1 and 4 are brought into conduction. For clarity, the transistors and wires are colored red and brown. Transistor 1 (red) connects terminal A to the positive, and transistor 4 (brown) connects terminal B to ground.

Because transistors 2 and 3 are not brought into conduction, no current flows through them. If this were the case, a short circuit would occur.

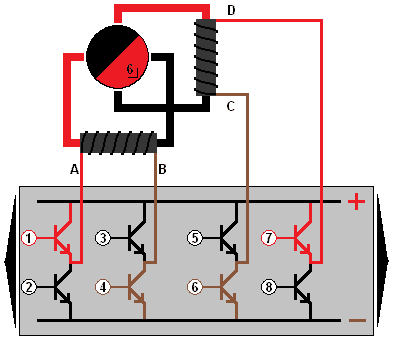

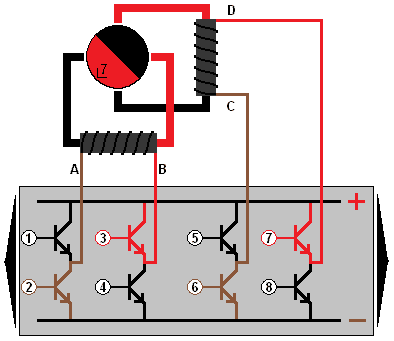

In the image, the stepper motor is rotated a little further. Transistors 6 and 7 must also be brought into conduction for that.

To rotate the stepper motor a little further again, the conduction of transistors 1 and 4 stops. Only transistors 6 and 7 continue to conduct, which causes the stepper motor to take position 3.

For the next step, transistors 2 and 3 must be brought into conduction.

Variable Reluctance Stepper Motor (VR):

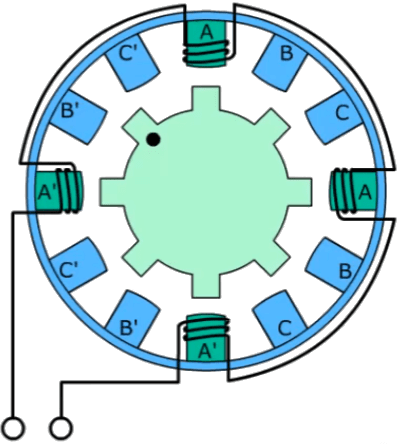

Like the permanent magnet stepper motor, the variable reluctance stepper motor contains stator poles with coils. It distinguishes itself from the previously discussed stepper motor with its toothed rotor of ferromagnetic metal, such as nickel or iron. This means that the rotor is not magnetic. This type of stepper motor is nowadays very rarely used.

The stator coil on one side (A) is wound opposite to the coil on the other side (A’). The same naturally applies to B and B’, etc. The teeth of the rotor are attracted by the magnetic flux generated by energizing the stator coils.

The advantages of the VR stepper motor compared to the permanent magnet type are:

- Due to the absence of permanent magnets, the production of the VR stepper motor is less environmentally harmful;

- It is not necessary to reverse the polarity of the stator coils. This allows for simpler control;

The disadvantages are:

- Low torque;

- Low accuracy;

- Higher noise production. The number of applications, including in the automotive sector, is therefore limited;

- Due to the absence of permanent magnets, there is no holding torque at standstill.

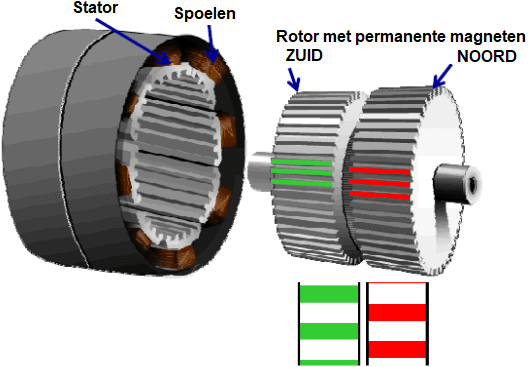

Hybrid Stepper Motor:

The hybrid stepper motor features a toothed rotor with permanent magnets and a toothed stator with eight coils with a small air gap between the rotor and stator. The rotor consists of two gear wheels that are offset by 3.6°. Inside the rotor, there is a large magnet. Two steel gears are pressed over the magnet. The gears are also magnetized due to the presence of the magnet. One gear is magnetized as the north pole, and the other as the south pole. Each tooth on the rotor becomes a magnetic pole. We therefore speak of the “north pole rotor” and the “south pole rotor”. By shifting the gears, the north and south poles alternate during rotation. Each gear has 50 teeth.

When the stepper motor driver allows current to flow through a stator coil, the coil becomes magnetic. The north poles of the coils will attract the south poles of the rotor, causing the rotor to rotate.

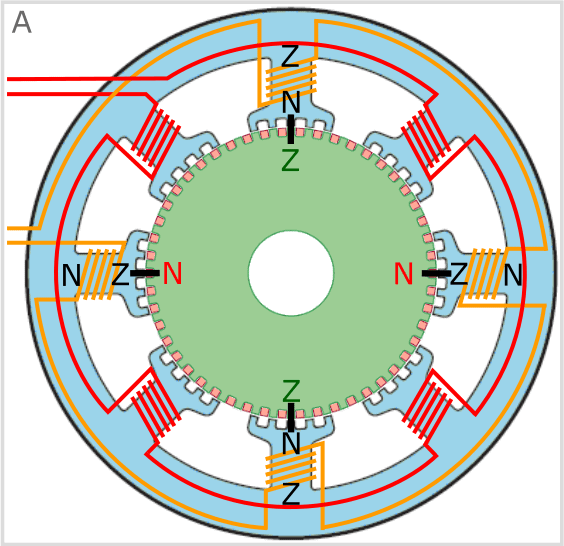

In the three images below, the control of the two phases (red and orange) of the hybrid stepper motor is shown.

A. The rotor of the stepper motor is rotated to the current position (see image) because the shown coils are magnetized.

- The green gear is the south pole, which is attracted by the north poles on the stator;

- The teeth between the rotor and stator align in the places where the rotor has been drawn to. For clarity, these points are marked with a black marking in all three situations;

- The red gear is behind the green gear. Because the gears are rotated relative to each other, the red teeth are visible. The north poles on the rotor are attracted by the south poles on the stator.

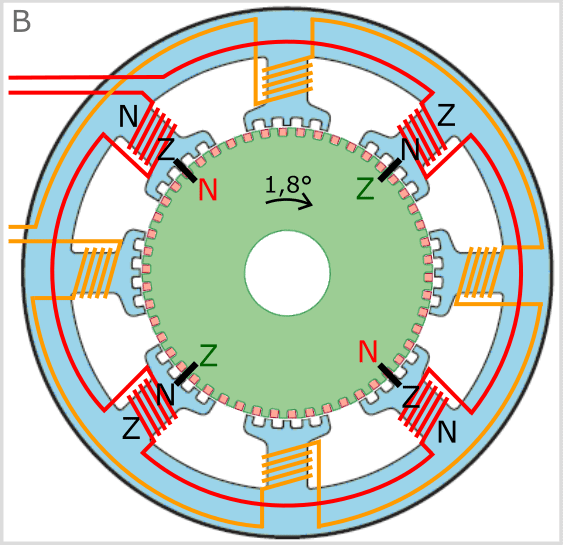

B. The control has switched phases. The magnetic field between the orange coils and the rotor has disappeared. Now the coils of the “red” phase are controlled, building the magnetic field between the red coils and the rotor. ;

- As a result of switching the magnetic field from the orange to the red coils, the rotor rotates 1.8° clockwise;

- To rotate the rotor counterclockwise instead, the polarity (current direction) through the red terminals would need to be reversed. The current direction through the coil determines the direction of the magnetic field and thus the “position” of the north and south poles.

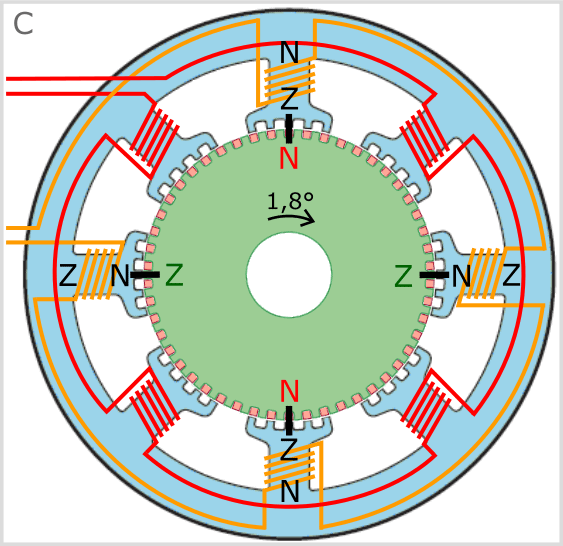

C. The control has again switched phases, causing the rotor to rotate another 1.8° with the clock.

- The same coils as in situation A are energized, but the polarity on the orange wires is reversed;

- The rotor can be rotated counterclockwise again by controlling the coils as shown in situation B;

- To rotate the rotor clockwise, the red coils are also energized, but the polarity is reversed compared to situation B.

In the examples above, it is shown that the north pole rotor is attracted by a south pole coil and at the same time the south pole rotor is attracted by a north pole coil. This ensures the hybrid stepper motor makes very precise movements and also has high torque.

The hybrid stepper motor can be configured with more pole pairs and more teeth on the rotor, allowing steps of up to 0.728° and 500 steps per revolution.

Related pages: