Topic:

Sankey Diagram:

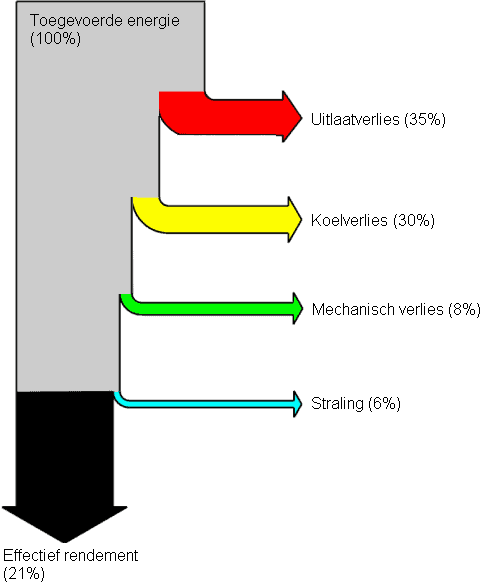

In the Sankey diagram (also known as the “Heat balance diagram”), the energy losses of the internal combustion engine can be shown. The Sankey diagram is derived from (and calculated using) the Seiliger process.

The fuel supplied to the internal combustion engine is mixed with air and ignited. Not all of the combustion energy is used to drive the engine (and the wheels). More than half of the combustion energy is lost to factors including:

- Drive losses (consider the drive of the coolant pump, air conditioning pump, distribution system, and other mechanical components)

- Transmission losses (converting the translational movement of the piston into the rotational movement of the crankshaft)

- Heat losses (heat from combustion is lost through radiation and reflection on engine components)

The remaining useful energy is referred to as the effective efficiency.

The Sankey diagram is depicted in the image. In the diagram, it is visible that 35% of the fuel is lost to exhaust gas heat, along with 30% cooling loss (heat lost to the coolant), 8% mechanical loss (drive and transmission losses), and 6% to radiation.

This diagram represents a gasoline engine. A gasoline engine has a relatively low efficiency of around 21%. This means that only 21% of a liter of fuel is used to “drive.” A diesel engine has a higher efficiency (up to 35%). For instance, cooling and radiation losses are less, but mechanical loss is somewhat higher. Therefore, a diesel engine has a different Sankey diagram than a gasoline engine.

To reduce cooling losses, a motor designer can choose to use a coolant pump with adjustable speed (possibly also switchable) or apply multiple cooling circuits. An adjusted design can ensure less coolant flows along the cylinder walls, resulting in less heat absorption by the coolant.

By using an exhaust turbocharger, exhaust gas losses can be reduced. This increases the effective efficiency. With a mechanical compressor, mechanical loss increases (since an extra component must be driven), but the effective efficiency increases significantly more. For instance, with an additional 5% mechanical loss, the effective efficiency can increase by 10%.

Related page: