Introduction:

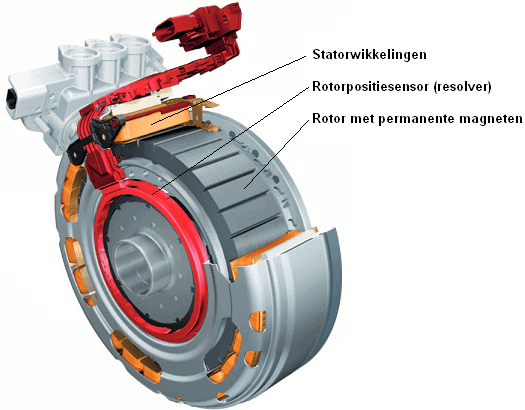

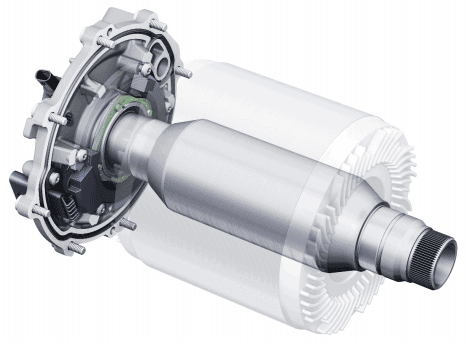

For the operation of the synchronous electric motor, it is essential that the correct coils are controlled by the inverter. To determine which coil (U, V, or W) needs to be energized, the inverter ECU reads the position of the rotor, which is measured by the rotor position sensor, also known as the “resolver.”

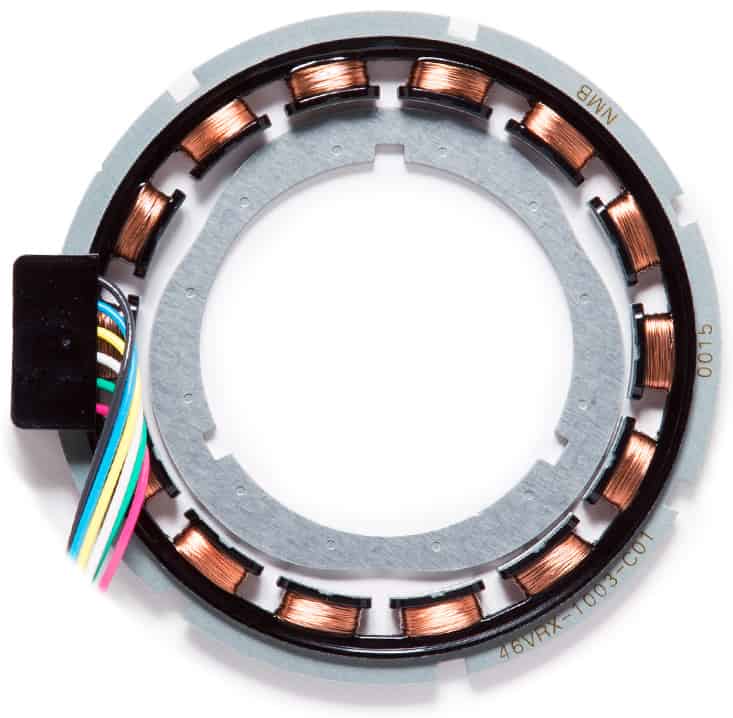

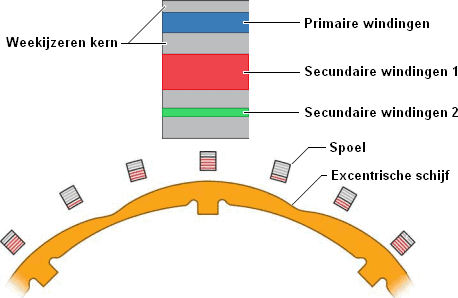

The resolver consists of an outer ring with several coils inside and a rotating eccentric plate. The distance between the eccentric plate and the coils changes continuously as it rotates.

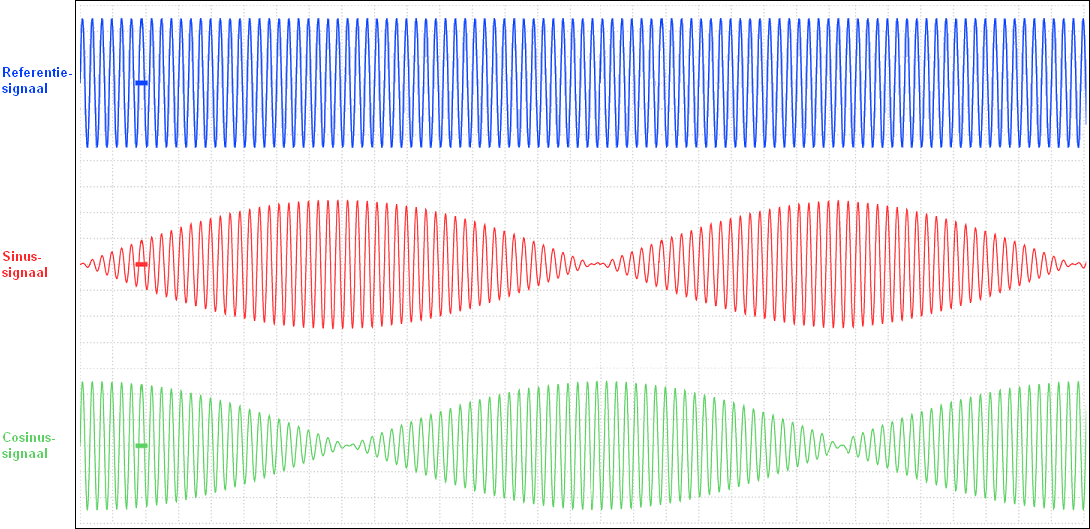

Signals from the resolver:

The ECU provides the resolver with a reference signal. The air gap between a coil and the eccentric creates a high or low sinusoidal alternating voltage. At a high amplitude in the red or green sinusoidal signal (see the image below), the air gap between the eccentric and the coil is small.

The resolver functions both at a standstill and when the electric motor is running: in both cases, the ECU must know the position of the rotor.

The image below shows the theoretical signals. In reality, the frequency is much higher, making the variation in the amplitude of the sine and cosine signals clearly visible.

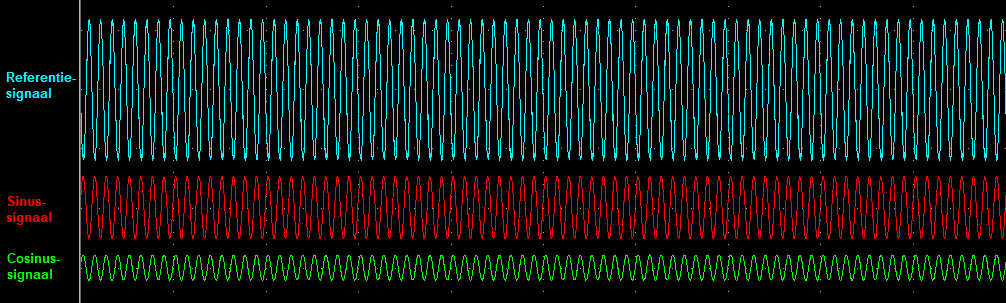

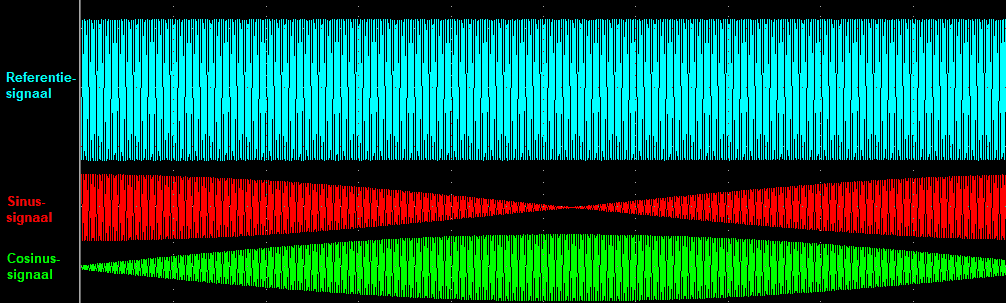

The two images below show an actual measurement on a resolver. Here, we also see the reference signal at the top, followed by the sine and cosine signals. The first image is at a standstill: the electric motor is not running. The height of the sine signal and the cosine signal remains constant. Based on the height of this alternating voltage, the ECU knows the rotor’s position at a standstill.

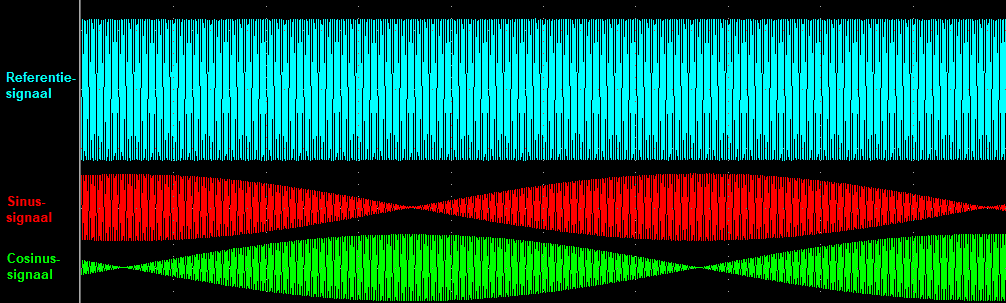

In the following two images, the time per division is reduced. The frequency of the reference signal on the resolver remains unchanged, but the measurement is taken over a longer time span. This clearly shows the changes in the amplitudes of the sine and cosine signals. The first image is measured at a low rotor speed and the second at an increased speed. With an increasing speed, the frequency of the sine and cosine signals becomes higher (more signals per time unit) while the amplitude (the height of the alternating voltage) remains constant.

Components of the resolver:

In the resolver of the VW E-Golf, there are 30 series-connected coils. Each coil in the resolver consists of a soft iron core with three different windings: primary, secondary 1, and secondary 2.

The primary coil (blue) is supplied with a high-frequency alternating voltage.

The number of secondary windings (1 red, 2 green) differs for each coil.

As the cam of the eccentric plate moves along the coil, the induction in the secondary windings is enhanced. Due to the number of windings in the secondary 1 and 2 windings in each coil, this also results in different voltages in the secondary windings. The ECU in the inverter can calculate the rotor’s position based on the voltages of the secondary windings 1 and 2.

The adjustment of the resolver on the rotor requires precise accuracy: many manufacturers specify that if there are problems with the resolver, the entire electric motor must be replaced. Once the resolver is accidentally disassembled, or the bolts on the outside of the electric motor housing are loosened, it cannot be reassembled correctly. In such cases, many manufacturers specify replacing the electric motor.

The exact rotor position of a synchronous motor must be known at standstill and while driving. When the sensor is defective, the vehicle can no longer drive.

For the asynchronous motor, monitoring the rotor position is not necessary. The rotor position sensor provides four pulses per rotor revolution. This measurement monitors the maximum amount of slip between the rotating magnetic field between the stator and the rotor. The Hall sensor is often used as a sensor. The Hall sensor sends pulses to the ECU when the rotor turns but cannot perform a measurement at a standstill, unlike the resolver of the synchronous motor. Manufacturers sometimes choose to use the resolver of the synchronous motor as a rotor position sensor.

Related pages: