Introduction:

The relay is widely used in automotive electrical circuits within the circuit for consumers that draw large amounts of current. The higher the current, the thicker the wiring should be. The wire diameter determines the maximum allowable current. We want to avoid using thick wires as much as possible, as this makes the wiring harness bulkier and more prone to faults. Another, even more important reason for using relays is control by the Electronic Control Unit (ECU). As the current increases, so does the amount of heat generated. We want to keep this heat away from the ECU as much as possible. Examples of electrical components controlled by a relay include:

- Engine cooling fan;

- Horn;

- Rear window defroster;

- Electronic Control Units (ECUs);

- Injectors and ignition coil (petrol engine);

- Fuel supply pump;

- Low/high beam and/or fog lights.

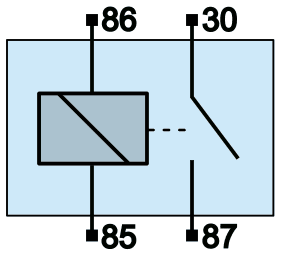

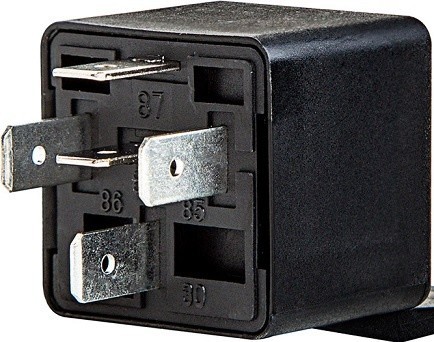

The following two images show a relay diagram and a real relay. The relay has four connection points with standard DIN symbols:

- Control current input (86)

- Control current output (85)

- Load current input (30)

- Load current output (87)

The relay switches a small control current into a large load current. This is a standard phrase known by many students and technicians. However, when it comes to measuring in relay circuits, confusion often arises about the codes: where does the control current flow and where the load current? How should you measure to confirm the relay works properly? The following sections explain how a relay works, which voltages should be measured on a healthy relay, and how to trace faults.

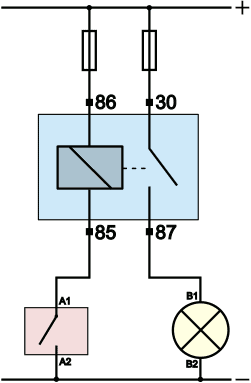

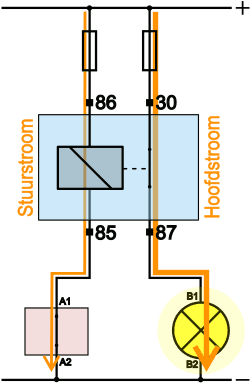

The image below shows a relay in the deactivated and activated state.

- Relay deactivated:

The switch (red frame) in the diagram is between the relay output (terminal 85) and battery ground (car chassis). In reality, this switch can be located in the dashboard, like the fog light switch.

- Relay activated:

When the driver operates the switch, the contacts close and the control current circuit is closed. Current flows from the positive battery terminal through 86, then through the relay coil, from 85 through the switch to ground. As the current passes through the relay coil, it becomes magnetic and pulls the contact switch between terminals 30 and 87, also closing the circuit there. Load current flows from the positive battery terminal, then through the fuse to relay terminal 30, and then through terminal 87 to the electrical load being controlled.

In the diagrams, the lamp is usually used as a load, but of course, it can also be other electrical loads/actuators. The type of load controlled by the relay does not affect the relay circuit.

Typically, the control current through the relay is between 150 and 200 mA (0.15 – 0.2 A). The load current can be up to 20 or 50 A. The maximum allowable load current is usually written on the relay housing.

Relay circuits:

The relay is activated via a low current control circuit, operated either by a manual switch or by an Electronic Control Unit (ECU). The latter type is found in most modern vehicles.

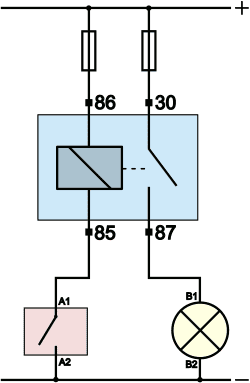

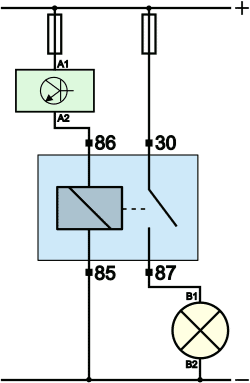

The relay can be controlled via the positive supply or via ground. This does not affect the relay’s operation: as long as the relay receives both positive and ground, current will flow through its coil. The three images below show a ground-side control circuit with a switch and ECU, as well as a positive-side control circuit.

Relay installations controlled by the ECU offer several advantages:

- The driver can send a command to the control unit to operate the load, either via a dashboard switch or the main computer (sometimes via the multimedia display);

- The ECU itself can activate or deactivate the relay based on a sensor signal (for example: engine temperature rises and the fan is switched on), or shut down the fuel pump after a crash event detected by the airbag ECU. Regulation via the ECU provides greater convenience and a higher level of safety.

In the diagrams in this image, terminal 86 is the input and 85 is the output of the control current circuit. In practice, manufacturers may swap these two terminals: 85 may receive 12 V and 86 be connected to ground. Thus, the relay can be activated by either the positive or the ground side. This is usually specified in the diagram or can be measured on the vehicle.

Measurements with relay deactivated and activated:

The composition of the control current and load current was explained in the introduction. When an electrical load fails, you usually start by reading the fault codes and measuring the voltage at the load. By measuring V4 you can detect if there is contact resistance or an open circuit in the supply or ground lines. If there is a broken wire, a blown fuse, or the switch remains “open”, you will measure a non-zero value at V3 and/or V4: this means there is a problem. This section explains the ideal measurements needed to verify voltages at the relay. We assume terminal 86 is the input and 85 is the output for the control current side. As mentioned previously, manufacturers may swap these connections.

Relay deactivated:

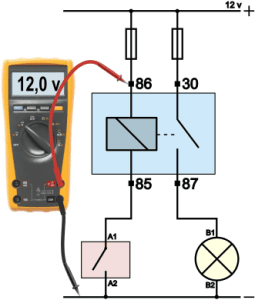

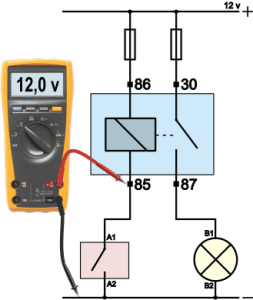

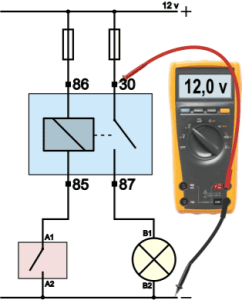

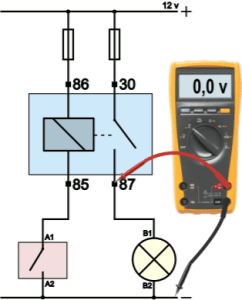

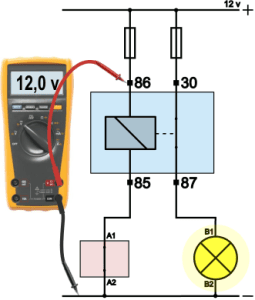

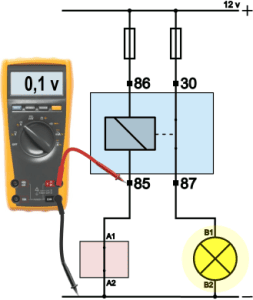

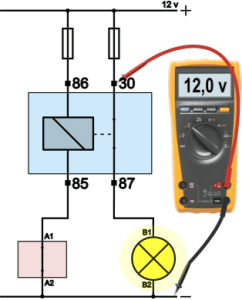

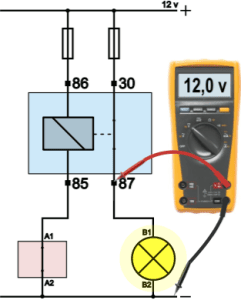

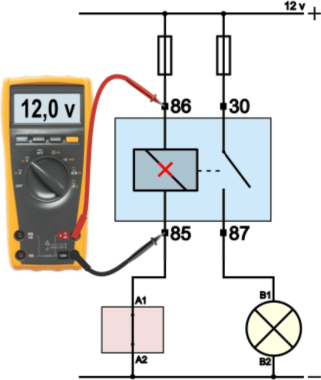

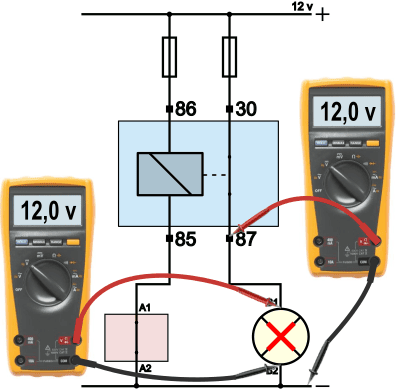

This text relates to the measurements shown in the four images below. When the relay is deactivated, use the voltmeter to measure voltage at all four terminals (86, 85, 30, and 87) relative to ground (car chassis or an alligator clip on the negative battery terminal).

- Measurement 1: Control circuit input (terminal 86) shows 12 V (or 24 V in trucks);

- Measurement 2: No voltage is consumed with the relay deactivated, so there is 12 V at terminal 85;

- Measurement 3: Load circuit input (terminal 30) shows 12 V;

- Measurement 4: Since the relay is deactivated, the internal switch is open and terminal 87 shows 0 V.

| Terminal 86: | 12 V |

| Terminal 85: | 12 V |

| Terminal 30: | 12 V |

| Terminal 87: | 0 V |

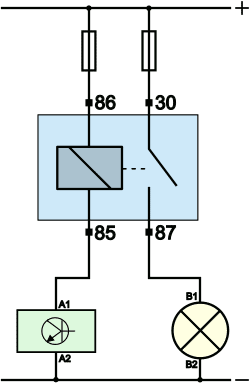

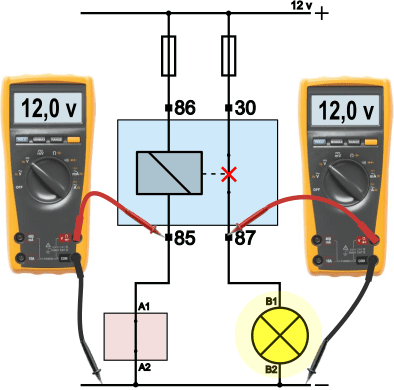

Relay activated:

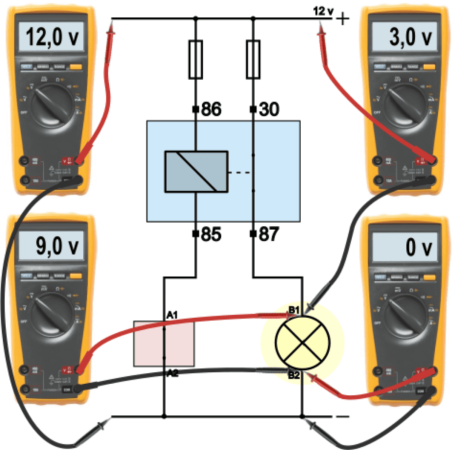

The switch is closed. Connection points A1 and A2 are connected. The control current circuit is closed and current starts to flow. With the relay activated, repeat the voltage measurements at all four terminals (86, 85, 30, and 87) relative to ground.

- Measurement 1: Control current input (terminal 86) shows 12 V;

- Measurement 2: The voltage is consumed and converted into magnetism in the activated relay, so terminal 85 has 0.1 V;

- Measurement 3: Load circuit input (terminal 30) shows 12 V;

- Measurement 4: With the relay activated, the switch inside the relay is closed and terminal 87 shows 12 V.

| Terminal 86: | 12 V |

| Terminal 85: | 0.1 V |

| Terminal 30: | 12 V |

| Terminal 87: | 12 V |

Troubleshooting:

When an electrical load or actuator does not work properly, we can measure the voltage at the relay terminals to determine the cause. If the relay does not operate when triggered, it could be a faulty relay, but if the fuse is blown and input voltage does not reach the relay, it cannot switch any current. By taking four measurements at the relay (always relative to ground), we can eliminate many possibilities and pinpoint where the open circuit is. In the examples below for possible faults, the red X marks the fault location, and the voltmeter reading shows the voltage difference between measurement points.

Fault 1: Relay does not work

The relay is connected to ground via the switch but no control current flows, so no load current flows either, and the voltage at terminal 87 remains at 0 V. This prompts us to measure the other terminals. After switching on the system, if you measure a voltage difference of 12 V between terminals 86 and 85, this indicates a broken coil.

The voltage drop across a healthy relay is usually 12 V, as the voltage is consumed. The same 12 V difference will also be measured if the coil is broken: the red probe will have 12 V while the black is connected to ground (via a closed switch), and will read 0 V.

If you suspect an open relay coil, measure resistance. The relay must be removed and disconnected from the circuit. Then you can measure the resistance between terminals 86 and 85 on the relay.

- Coil resistance: between 60 and 80 Ω = good

- Coil resistance: very high (1. or OL): coil open

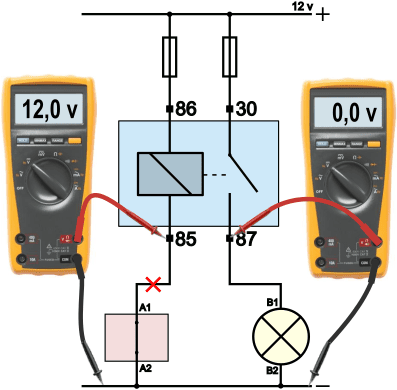

Fault 2: Relay does not work

When the switch (red frame) is operated or after ECU activation, the load does not work. When measuring at terminal 85 we find 12 V relative to ground. This means the voltage is not consumed in the coil and therefore the coil has not become magnetic.

The differential measurement between terminals 85 and A1 on the switch will indicate whether the wire is broken or if the problem is with the switch itself:

- Voltage difference between 85 and A1: 12 V = wire is broken

- Voltage difference between 85 and A1: 0 V = problem is not the wire.

If the wire is intact, there will be 12 V on both sides of the wire, so the difference is 0. If you measure a 12 V drop across the switch (A1 relative to A2), the break is in the switch; it remains open. This can be measured when the switch is not pressed.

Fault 3: Load stays on constantly.

The customer may complain that the cooling fan keeps running, even with the vehicle stopped and switched off. Or there may be a complaint about battery drain: the battery discharges quickly even though the battery and charging system are good. In this case we are dealing with a parasitic drain.

Measurements show that the control current is not flowing (12 V at terminal 85), but the load current still flows.

The cause here is sticking relay contacts (plakkend relay): the switch between terminals 30 and 87 remains closed even with no magnetism in the coil. The reason is usually wear or burned/oxidized contacts.

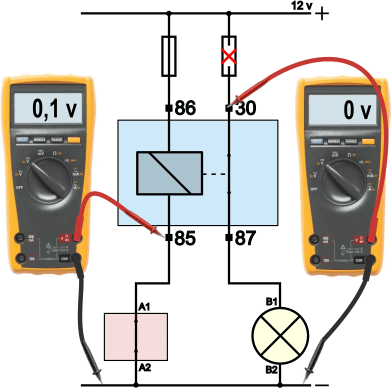

Fault 4: Relay works but load does not

When the relay is activated you often hear the click between terminals 30 and 87. There is 12 V at terminal 86 and 0.1 V at terminal 85 relative to ground, meaning the control current flows and the voltage is consumed in the coil. If you then find 0 V at terminal 30 relative to ground, this means the relay closes the load circuit but no supply voltage reaches it; the reason here is a blown fuse.

The fuse only blows if a current above the permitted maximum flows through it. It is important to search for the cause of this. There may be too many loads connected to the same fuse (e.g. several 12 V outlets), or an incorrect fuse may have been installed previously.

Fault 5: Relay works but load does not

If all voltages at the relay’s four terminals are normal, this means the relay is being switched correctly, the voltage is good and operation is fine. The voltage at terminal 87 switches from 0 V to 12 V when the relay is activated, then back to 0 V when deactivated.

If the load still does not function in this case, the likelihood of a fault in the load is very high, or there is an open circuit between the relay and the load, or between the load and ground. The V4 measurement across the load will identify the fault location.

If the voltage across the load is equal to the battery voltage (12 V), the load itself is faulty. In this example, the lamp wire is broken.

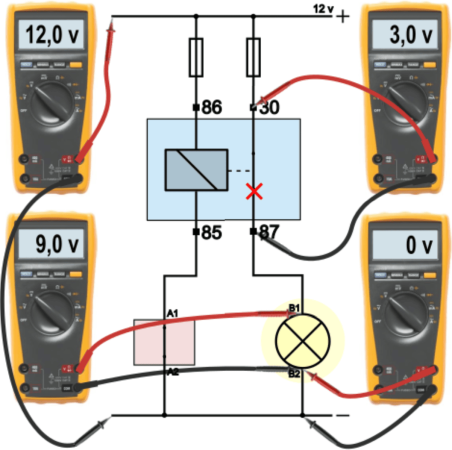

Fault 6: Relay works, load works but not efficient enough

The load works but at reduced performance. For a lamp this may be visible as dim lighting while other lamps work normally. Or the load may be an electric motor running slowly or a horn sounding weak. In these situations we take a V4 measurement on the load circuit; there is no need to check the control circuit.

In the left bottom image, V4 measures that the lamp operates at 9 V while battery voltage is 12 V. In V3 (from positive to lamp positive) we find a voltage difference of 3 V. This loss occurs in the positive circuit. Further measurements determine the source of the voltage drop: before, in, or after the relay (between terminals 87 and B1). In the lower right image, it is seen that the voltage drop across the relay (30 to 87) is 3 V, indicating the loss is within the relay itself, usually due to dirty or burned contacts causing contact resistance.

Summary:

Because of the detailed explanation of faults and large images, the causes of the different faults are summarized here:

- Fault 1: Relay does not work because its coil is open, so current does not flow through it and it is no longer magnetic. An open coil can be detected by measuring resistance: 60 to 80 Ω is good, very high means open;

- Fault 2: Relay does not work due to an open wire between terminal 85 (control current output) and the switch. Voltage at terminal 85 stays at 12 V even after relay activation;

- Fault 3: Relay sticks and the circuit remains closed; voltage at terminal 87 remains at 12 V even without a control command. This can be noticed audibly or visually, and in the case of parasitic drain the battery keeps discharging for no obvious reason;

- Fault 4: Relay works, but because of a blown fuse the load does not work;

- Fault 5: The load is faulty and does not work. Control issues have been excluded by the four relay terminal measurements;

- Fault 6: Contact resistance causes poor performance of the load/actuator. V4 determines the location of the resistance. In the example, a voltage drop between 30 and 87 inside the relay indicates the loss is caused by contact resistance at the relay contacts.

Conclusion:

From these six possible faults that can occur in vehicles, the importance of knowledge and skill in measuring voltages at the relay is clear. Measuring all four terminals can quickly guide you to the problem source: whether it is at the control current input or output, load current input or output, or within the relay itself.

Relay locations:

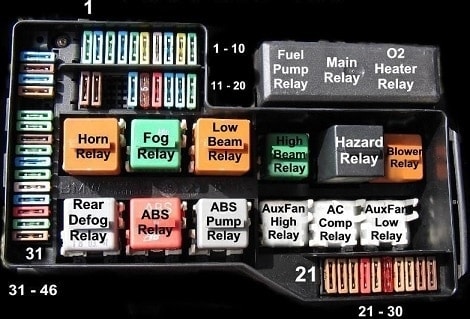

Relays are usually mounted together in one specific area within the car, such as in the fuse box (as shown in the image) or on a separate relay board, but there may also be relays in the engine compartment, such as the cooling fan relay. Relay locations can be found in the vehicle handbook or the vehicle’s workshop manual.