Topics:

- Tuning the engine management system

- VE table

- AFR table

- Ignition advance table and Cold Advance

- Dwell-battery correction

- Ignition and start, Cranking Pulse

- Idle

- Acceleration

- Priming pulse

- Additional enrichment

Tuning the engine management system:

The previous chapters described how the engine was prepared and the choices made to shape the engine management system. The implementation described how the obtained data was processed in the engine management system. Entering all the parameters is not yet sufficient to make the engine run. It needs to be “tuned”, where adjustments are made based on measurements and empirical results.

The software tuning of the engine greatly influences its operation. Incorrect tuning can cause irregular running, stalling, and even lead to engine failures. The latter can occur with a too lean mixture. The injection time and quantity depend on several factors:

- RPM;

- Load;

- Temperature.

To consistently achieve good mixture formation under varying operating conditions, the ECU must be properly set before the first engine start. The settings are accomplished through entering several tables, namely:

- The VE table for volumetric efficiency;

- The AFR table for the air/fuel ratio;

- The ignition table for ignition timing.

The tables are entered into the TunerStudio program. Entering incorrect values can result in engine malfunction; hence, system knowledge is essential here. The following paragraphs explain how the tables are determined. The base injection time, without enrichment, is established through several calculations.

The specific mass of the air (ρ) is calculated from the measured temperature of the intake air and the vacuum (the value of the MAP sensor). It is clear that well-filled tables are necessary for the proper functioning of the engine.

VE table:

The chapter injection system explains the purpose of the VE table. This section explains how the data for the VE table was established for the Land Rover engine.

In the VE table, each cell indicates the percentage associated with the vacuum relative to the RPM. This percentage will be highest at the RPM where the torque is highest. At this point, the engine is most efficient because it fills the best. The torque and power curve of the Land Rover engine is shown in the image below.

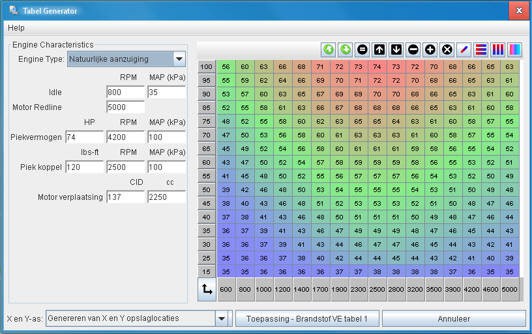

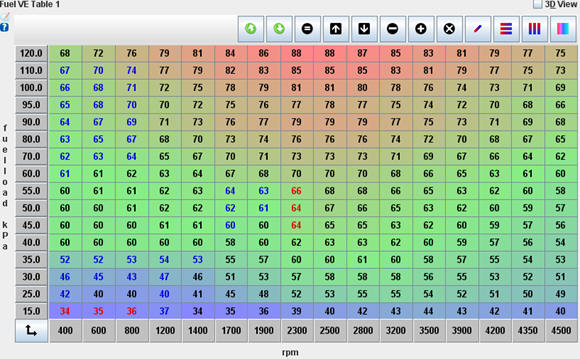

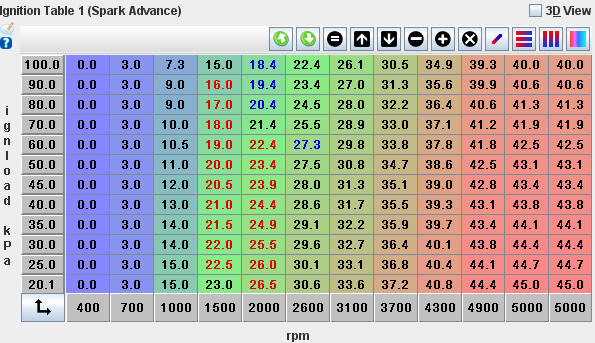

The image shows a VE table filled in with a generator. The Y-axis indicates the pressure in the intake manifold registered by the MAP sensor. 100kPa is equal to 1 bar (atmospheric pressure) and is the maximum pressure in the intake manifold of a naturally aspirated engine. The X-axis indicates the engine RPM.

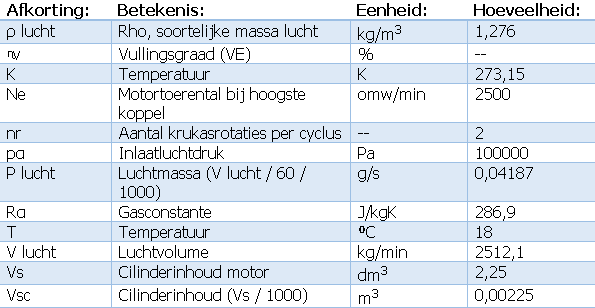

Before the engine is started for the first time, the VE table must be filled in by estimation. The final setting of the VE table should be performed on a test bench using a wideband O2 sensor and a disabled lambda control. The TunerStudio program, which provides the MegaSquirt with software and parameters, includes a utility for calculating the values in the VE table. However, the VE values can also be calculated using formulas. The data from the table is used to fill in the formulas.

V air is determined under the same conditions as in an earlier calculation; namely, at the engine RPM where the torque is highest. The result from an earlier calculation is therefore taken over in the following formula.

The (vacuum) pressure in the intake manifold and the intake air temperature affect the specific mass of the air, and therefore also the formula of the volumetric efficiency. With the known and calculated data from table 3 and this formula, the volumetric efficiency can be determined.

In the cell at 2500 RPM and 100kPa in the VE table, 70% can be entered. This is in the top row of the number series, where the throttle valve is fully open. Calculations can be repeated several times to fill in other numbers in the VE table. Intermediate cells can be generated using an interpolation function. The computer thereby determines the intermediate values through a linear progression. This ensures that the “hill” seen in the 3D view is as smooth as possible, with no dips or points in between. When the cells in the 100 kPa range between idle and maximum RPM are filled in, the torque curve can be deduced from this. When the torque, for example, is halved at maximum RPM, the VE value will also be half the maximum value; in this case, approximately 35%. If it’s decided to estimate the cells, the entire VE table can also be filled in this way. The VE table assembled with the previous calculations and reasoning will be good enough to run the engine, but certainly not correct. The final setting of the VE table must take place on a test bench using a wideband O2 sensor and disabled lambda control to prevent AFR corrections, where the engine can be loaded for an extended period. Since a test bench is not used for this project, the setting will be performed as well as possible in the idle area and with increased RPM at low load.

Getting it to idle smoothly is the hardest part and is done last. It is advisable to keep the engine at an increased RPM (about 2000 RPM) and let the engine warm up until it reaches operating temperature. Temperature changes then have minimal impact on the VE values. After the complete VE table is corrected, corrections for lower temperatures (e.g., during a cold start) can be entered. This is possible in separate setup programs such as cold start enrichment.

The maximum engine RPM is a factor that must be considered when filling in the table. With a table of 16 * 16 = 256 cells, it’s more accurate for intermediate RPMs to limit the maximum RPM as much as possible. There’s no point in filling the table up to 7000 RPM when the maximum RPM is 4500 RPM.

When adjusting the VE table filled in by approximation, the correct percentage for the correct intake manifold pressure (MAP) and RPM will be checked against the actual lambda value. This value must be obtained by adjusting the VE value to λ = 1. If, for example, a mixture ratio of 12.3 is measured while 14.7 is set in the AFR table, the VE value must be decreased until a mixture ratio of 14.7 is measured. By lowering the VE value, less fuel will be injected. The mixture becomes leaner.

The Innovate wideband O2 sensor with an external controller measures the mixture composition and communicates it to the MegaSquirt as a voltage between 0 and 5 volts. The software converts this voltage value into an AFR value (e.g., lambda = 1). After measuring and adjusting various cells in the VE table, intermediate cells can be automatically filled in by interpolation. Adjusting the VE value results in a different injection strategy. The control of the injector is derived from the value indicating how much air is present in the engine: namely, the value in the VE table.

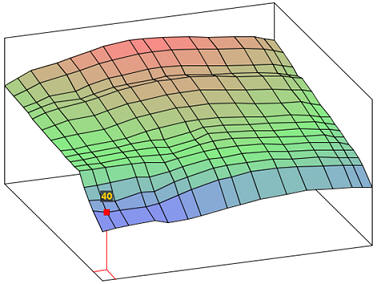

Unfortunately, we did not have access to a dynamometer, and it was not possible to test the engine under load on the road. Therefore, we are somewhat limited to running without load. However, there is a brake drum present that originally serves as a parking brake. This brake can be temporarily applied to load the engine. With a gear engaged (for example, the fourth) and a powered brake, the lambda value can be corrected at certain RPMs. We correct the intermediate values using the interpolation function. It is possible that detonation occurs during the test. In an earlier stage, the ignition table was filled in, where the ignition advance was entered. The desired advance may possibly deviate from the entered values in the table. If light detonation noises are heard, the ignition should be retarded a few degrees. A degree or three is often enough. This can, of course, be adjusted later once the VE table is completed. The values of the VE table can also be shown in a 3D view. This makes it clear whether there are no major deviations, such as differing points and dips.

Not only can it be verified if the values the generator calculated are logical, but the VE table could also be partially filled in without the use of the generator. The engine is most efficient around the RPM where the torque is the highest: at this point, the volumetric efficiency is highest and the value in the VE table is also highest. After all, the VE table indicates the volumetric efficiency of the engine as a percentage.

Once the VE table is completely filled, the lambda control can be reactivated.

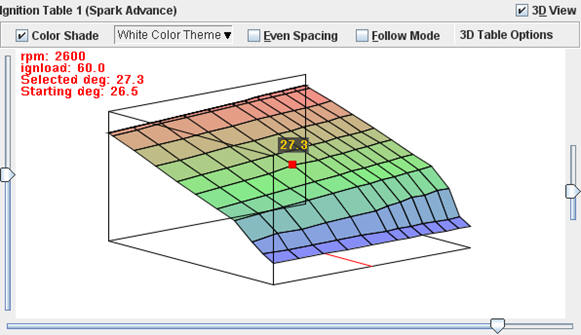

The images below show the filled VE table and the 3D view with which the Land Rover engine operates well.

AFR table:

The page on the injection system describes the function of the AFR table, and why leaning and enriching are necessary for power delivery and fuel efficiency. This page describes how the AFR table is set up for the Land Rover engine.

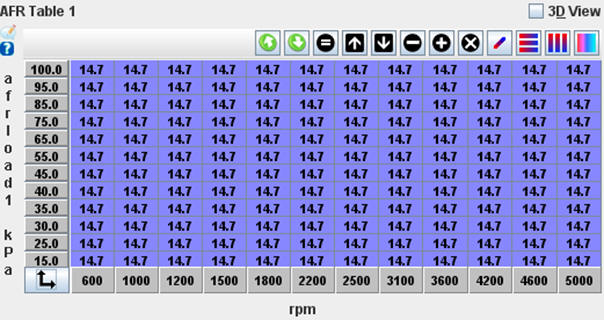

The VE table is set first, and only after that is the AFR table corrected. The AFR table must be initially set entirely to 14.7 so that the MegaSquirt does not make corrections when the VE table is filled in (see image). Initially, a stoichiometric mixture ratio is assumed. The lambda control is also disabled. Only after setting up the VE table is the AFR table filled in, and the lambda control is activated.

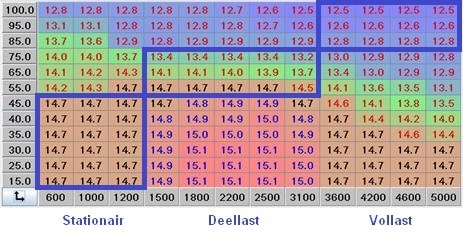

The image shows a filled AFR table, where the air/fuel ratio varies between 12.5 (rich) and 15.1 (lean). When filling in the AFR table, the mixture will be enriched in the full load area. The enrichment can be seen across the entire area between 75 and 100 kPa. Here the throttle is fully open. During partial load and around the torque RPM, the mixture is lean; the mixture ratio here is 15:1. This can be seen between 1500 and 3100 RPM at a vacuum of 15 to 40 mbar. Here the throttle is only partially open. In this area, the engine is most efficient.

Ignition Advance Table and Cold Advance:

The page ignition system describes what ignition advance entails.

The ignition advance table is set according to the factory data of centrifugal advance with vacuum regulation. The black line indicates the mechanical advance.

The blue line represents the map-controlled regulation. To avoid entering the part-load pinging area, a correction is applied; the actual advance follows the red line.

In the 3D view, it can be seen that there are no abnormal values, such as dips or humps. The table should be reasonably “smooth” and should not have too many bumps.

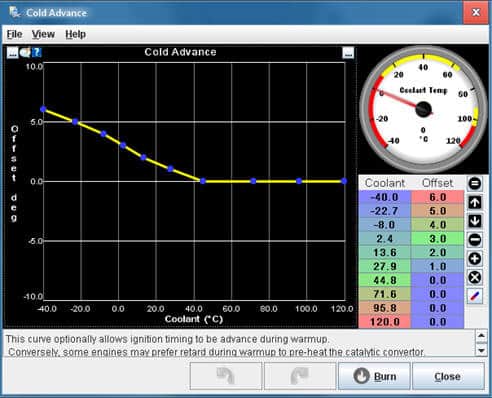

In addition to the standard settings in the ignition table, there is the possibility of additional advance with “Cold Advance” when the engine is cold.

When the engine is cold, more advance is needed because combustion occurs more slowly. To compensate for this delay, the advance is increased by up to 6 degrees. The image shows these settings.

Dwell-battery correction:

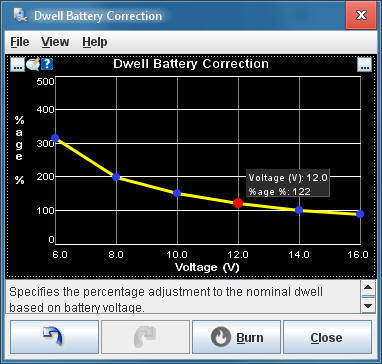

On the “Actuators” page, in the paragraph on the applied ignition system, the influence of the battery voltage on the charging time of the primary coil is described. The image shows the setting screen, where the already calculated corrections are entered.

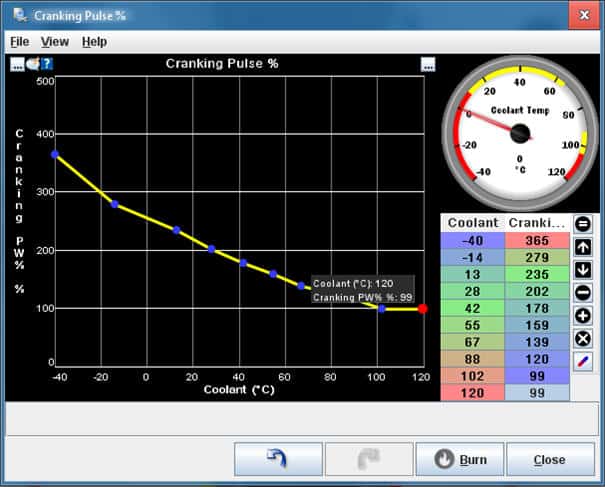

Ignition and start, Cranking Pulse:

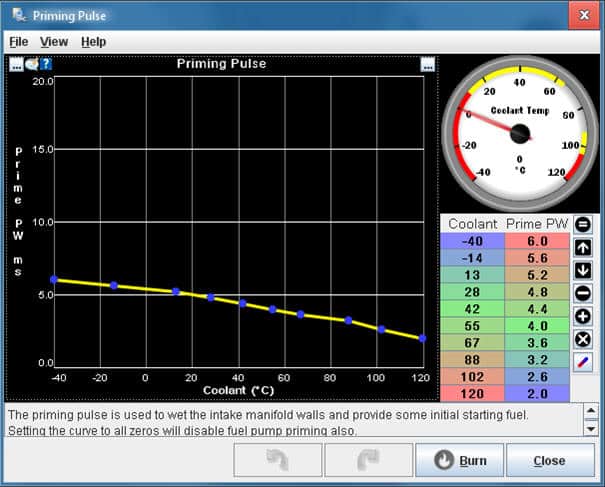

After the ignition is switched on, not only the fuel pump is energized, but the injectors are also activated once. This is called the “priming pulse.” The gasoline injected during the priming pulse settles on the – likely – cold walls of the intake manifold. The starting process will now proceed more easily because the gasoline injected during starting is not lost to the aforementioned situation. The amount of fuel injected during the priming pulse depends on the engine temperature. A warm engine requires a lower priming pulse. The desired quantity can be set in a graph in TunerStudio.

The starting RPM is often less than half of the idle RPM. The so-called “Cranking Pulse” must be set in the MegaSquirt. Since no throttle is given during starting and the throttle remains in a closed state, the required air must come through the idle control valve. It is possible to set a throttle position where injection is terminated. In this project, a stepper motor is used. This stepper motor is partially opened during starting. The position depends on the coolant temperature; more air if the engine is cold and less with a warm engine. Besides the air supply, the injection also needs to be adjusted to the conditions under which the engine is started. The amount of gasoline is adjusted by varying the injection time. At a coolant temperature of 25°C, the injection quantity is doubled compared to a situation where the engine is at operating temperature (around 90°C). The image shows the curve where the injection quantity can be set relative to the coolant temperature. A PWM of 100% is equal to the calculated amount of fuel; anything above that is additional enrichment.

Idle:

The throttle must be completely closed during idling. The air supply during idling is fully regulated by the applied stepper motor.

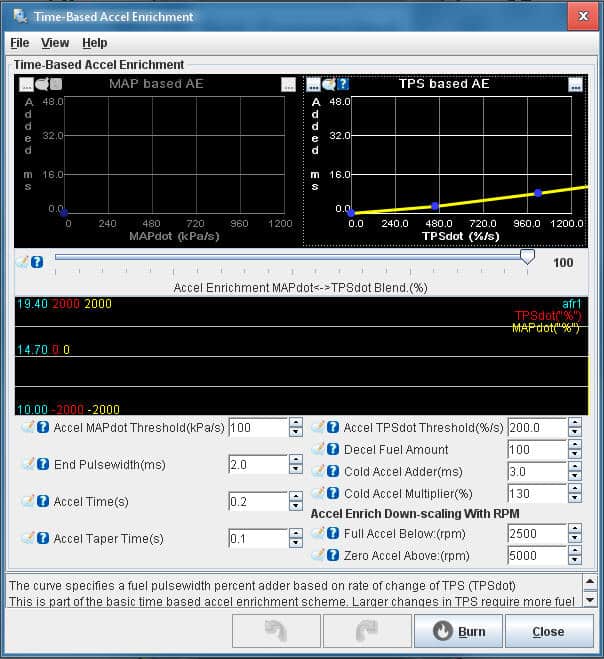

Acceleration:

Accelerating requires a richer mixture. The mixture ratio should be adjusted to the speed at which the accelerator pedal is pressed. In the TunerStudio program, the acceleration enrichment is set with the option “Acceleration Enrichment”, abbreviated as “AE”. The setting of the acceleration enrichment should only be done after the VE table is correctly filled in.

Since the engine in this project is equipped with both a throttle position sensor and a MAP sensor, both the throttle position and the vacuum in the intake manifold can be determined. TPS-dot is used for the change in throttle position. The “Dot” indicates the speed of the change and is expressed as a percentage. Depending on this percentage, more fuel is injected. The injection duration is extended by a few milliseconds. A TPS-Dot value of 100% indicates that the throttle has moved from closed to fully open in 1 second. If the opening occurs even faster, the percentage will increase. It is important to know from which value the throttle is opened; if the engine has been running at part-load for some time before accelerating, it cannot be assumed the throttle was fully closed. The position in which the throttle is located is indicated as a so-called acceleration threshold, or “threshold”. The threshold indicates from which throttle position one moves to a fully open throttle. The acceleration taper indicates the transition time from the acceleration injection time to the end of the injection enrichment. This prevents the acceleration from ending too quickly.

The setting of the acceleration enrichment can initially be checked with the simulator. A final adjustment must be determined empirically, with or without the help of the wideband O2 sensor.

Priming pulse:

The priming pulse is a function to spray a small amount of fuel onto the intake valves when the ignition is turned on. This facilitates the starting process. In the case of a warm engine, the injection quantity decreases. The priming pulse is adjusted with the blue dots in the curve (see image).

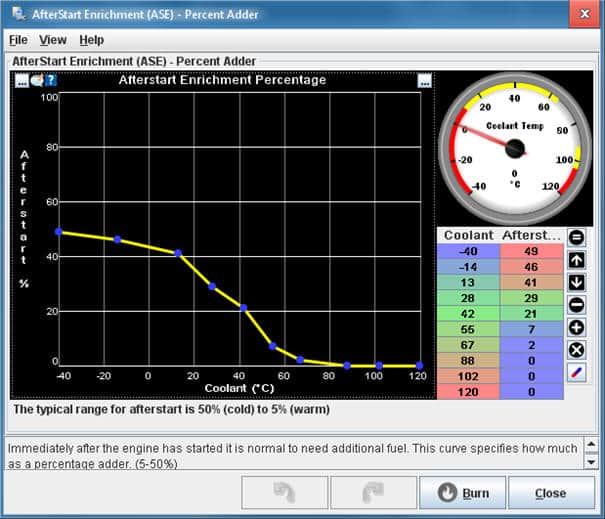

Additional enrichment:

Immediately after the engine starts, enrichment is applied. This is called “AfterStart Enrichment”. The MAP is still too high because the RPM is not yet high enough to provide sufficient vacuum. Especially with a cold engine, enrichment occurs for a certain period until the engine starts running according to the VE settings.

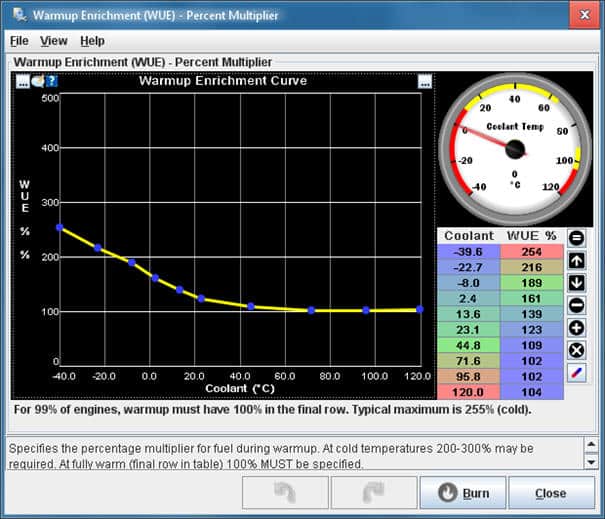

The “Warmup Enrichment” (WUE) provides enrichment during the engine’s warm-up phase. When the engine approaches operating temperature, the enrichment should be 0%.

Next: Testing.