Measuring Piston Diameter:

We can determine the diameter of a piston using a micrometer. The micrometer is applied perpendicular to the piston pin; at this point, the greatest forces occur due to the guide force. When wear occurs on the piston, the diameter will reduce most at this point.

The piston size is specified in the manufacturer’s technical data.

Measuring Cylinder Diameter:

The cylinder diameter can increase due to wear, also as a result of the guide force. With the cylinder measurement, we can determine whether there is wear and the extent to which any wear is within tolerances.

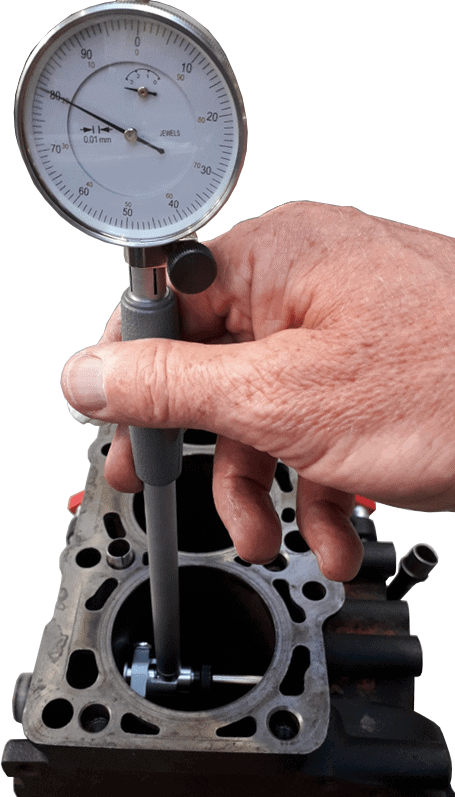

A cylinder measurement is carried out with a dial gauge attached to an inside micrometer.�

With a bore gauge, we can measure differences in diameter at various points in the cylinder space. This provides a wear pattern of the respective cylinder. The diameter can be measured accurately to 0.01 mm.

The bore gauge consists of a dial gauge, a connecting rod with a probe at the bottom, and an interchangeable rod. Depending on the cylinder diameter (bore), this rod should be chosen with the correct length. The case usually contains about ten different sizes. If the desired size falls precisely between two measurement calibers, a shim can be applied to the smaller caliber to achieve the desired length.

Example:

The cylinder diameter is 87.00 mm. We choose the rod with a length of 85.00 mm and mount a 3 mm shim to get a length of 88.00 mm. The length is now 1 mm greater than the cylinder diameter, which is important for this measurement because, in the event of wear, the cylinder diameter has increased. The length of the rod is determined with a micrometer.

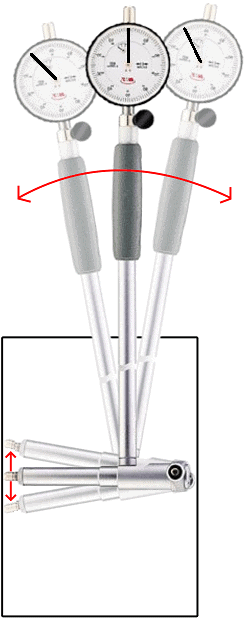

To begin the measurement, we insert the lower part of the bore gauge into the cylinder space. The following text concerns the measurement in the image:

- The right part has a non-adjustable wheel;

- The left part is the adjustable measuring pin, where a rod of the correct length has been mounted during setup;

To determine the smallest diameter, the bore gauge must be moved back and forth. The needle in the micrometer moves from left to right. In the image, three positions are shown: left, center, and right. The middle position is shown as dark gray, the other positions are light-colored.

- Move to the left position: measuring pin springs out of the bore gauge. The needle indicates 0.1 mm movement;

- Move to the right position: measuring pin springs out of the bore gauge again, and the needle also indicates 0.1 mm;

- Gauge in the middle: the cylinder diameter is smallest here. The measuring pin is therefore fully pressed in. The needle now reads 0 mm.

The needle does not have to indicate 0 mm if the bore gauge is centered. If one considers that the zero point is at 50 on the dial (the needle is rotated 180 degrees compared to the current situation), then the 0.1 mm deflection will cause movement between 50 and 60 on the dial; again 0.1 mm.

The above steps must be repeated in several places. When the gauge reads 0 mm in the center at all positions, there is no wear. However, if the needle moves past 0, the space has increased. The stroke of the needle has then increased: for example, a total of 1.1 mm instead of 1.0 mm. That means there is wear of 0.1 mm.

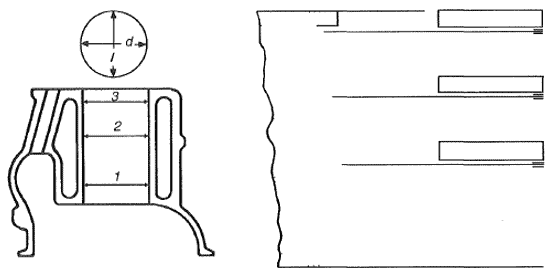

The following image shows a cylinder space with three possible measurement heights: 1, 2, and 3. The measurement should be performed in both the longitudinal and transverse directions.

The diameter at the top of the cylinder (3) will be the largest: the forces of the piston against the cylinder wall are minimal here. Halfway down the cylinder, the force is greatest. In the event of wear, this diameter will be the largest.

A tip is to sketch the measurement and note the measured values on it. When the diameter is larger than the manufacturer’s specified value, the respective cylinder is rejected.

Piston Clearance:

The clearance between the piston and cylinder depends on both the piston diameter and the cylinder diameter:

- piston wear: diameter becomes smaller;

- cylinder wear: diameter becomes larger.

Wear is a result of, among other things, the guide force generated when the piston is pushed downward by combustion pressure and the crank-connecting rod mechanism. More wear results in a greater distance between the piston and cylinder. The result is that the piston gains more freedom of movement and starts to “tilt.” This produces ticking noises, causes higher oil consumption (the lubricating oil can now easily enter the combustion chamber along the piston), and can only be rectified through extensive repair.

There must always be a certain piston clearance to:

- allow for expansion of parts during heating;

- maintain space for a lubricating oil film.

The maximum clearance between piston and cylinder is specified in the factory data. Therefore always read the values provided by the manufacturer. Generally, it is stated: the average piston clearance is maintained at 0.01 mm per cm of piston diameter. For turbo engines, this is slightly more, namely 0.015 mm per cm diameter. If we have a piston in this case with a diameter of 80.00 mm, the bore of the cylinder should be (80.00 + (8 * 0.01 mm) = 80.08 mm).

If the piston clearance is too large, one should check the factory specifications for possible next steps:

- Boring and honing cylinders, as well as installing oversized pistons due to the larger cylinder diameter, is not allowed by all manufacturers. One must also check whether such an adjustment has already been made in the past. Some manufacturers prescribe that a maximum of 3x an oversize may be installed;

- If installing oversized pistons is not allowed, or if the costs are too high, it may be better to replace the rotating assembly.