Introduction:

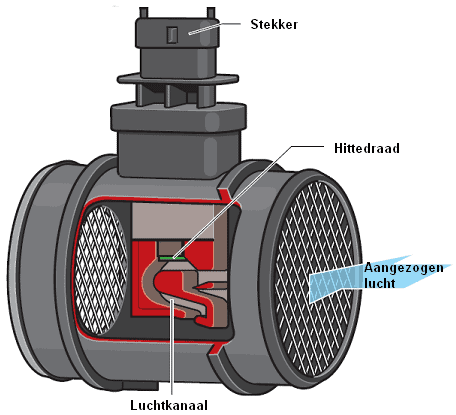

The mass air flow sensor is mounted between the air filter housing and the intake manifold.

All the intake air passes through the mass air flow sensor. In a naturally aspirated engine, the air is drawn in by the vacuum in the cylinders, and in an engine equipped with a turbo, the air is drawn in by the compressor wheel. The mass air flow sensor measures the amount of air flowing into the engine. Based on this data, the engine control unit can determine the amount of fuel to be injected using the mapped values in its control systems.

The mass air flow sensor is available in two versions:

- Analog output signal: the voltage level depends on the measured value, known as an AM signal (Amplitude Modulation);

- Digital output signal: the electronics within the sensor create a digital signal in the form of a frequency. This FM signal (Frequency Modulation) varies as the air volume increases.

The following paragraphs explain the difference between analog and digital mass air flow sensors with sample measurements. The final section explains the operation of the mass air flow sensor at the component level.

Analog Mass Air Flow Sensor:

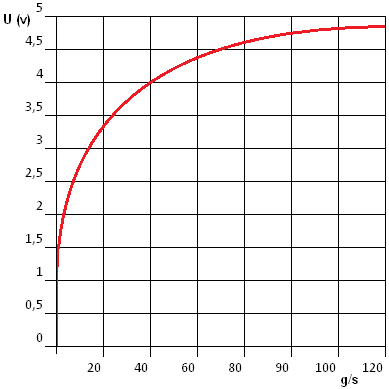

The supply voltage to this sensor is 12 volts. The analog voltage signal of this sensor generally (depending on the make and model) is:

- Ignition on, no airflow: 0.2 – 1.5 volts.

- Engine idling: 1.5 – 3.0 volts.

- Accelerating with a fully opened throttle: max. 4.5 volts.

The graph shows the voltage trend relative to the measured air mass in grams per second. The voltage can be measured with a multimeter.

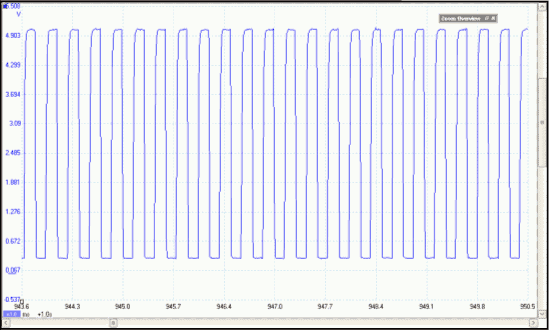

Digital Mass Air Flow Sensor:

The frequency of the signal indicates the amount of air that has passed the sensor. The signal voltage always ranges between 0 and 5 volts. The frequency shows how often the signal repeats within one second. If we measure two signals in one second using an oscilloscope, we refer to it as 2 Hz. In practice, the frequency is significantly higher. Manufacturers generally use the following frequencies:

- Idle: 2 – 2.5 kHz (2000 – 2500 Hz)

- High RPM: up to 6 – 6.5 kHz

The frequency increases proportionally with the increasing airflow. If you observe abnormal peaks in the signal, or if a low frequency is measured at high RPM, there may be a contaminated or defective mass air flow sensor. The images below show two measurements of the digital mass air flow sensor.

The voltage measurement shows the voltage trend over time. In this image, it is visible that the voltage constantly changes between 0.5 and 4.5 volts. With increasing airflow (when increasing RPM), the time between the rising and falling lines becomes shorter. The pulses become thinner and closer together. This oscilloscope image does not allow for a proper diagnosis.

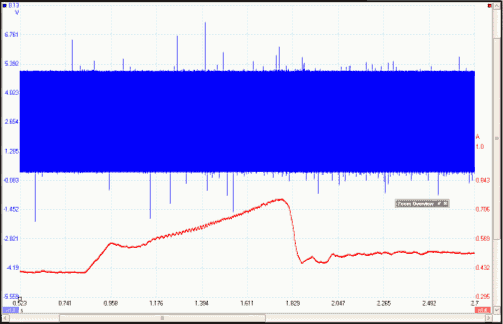

The measurement, which uses channel A to measure the voltage and channel B to measure the frequency, provides insight into the operation of the mass air flow sensor. Measurement is done over a longer time span, so it seems that the blue pulses of channel A are adjoining. However, due to zooming out, there is hardly any distinction between the rising and falling voltages.

The red line (channel B) indicates the frequency of the signal. The closer the voltage pulses are together, the more the red line rises. When accelerating the vehicle with a fully opened throttle to high RPM, the frequency continues to increase until the accelerator is released. The height of the red line indicates the maximum frequency of the signal. This data can be compared to factory data or a calculated value. We will delve more into this in the next section.

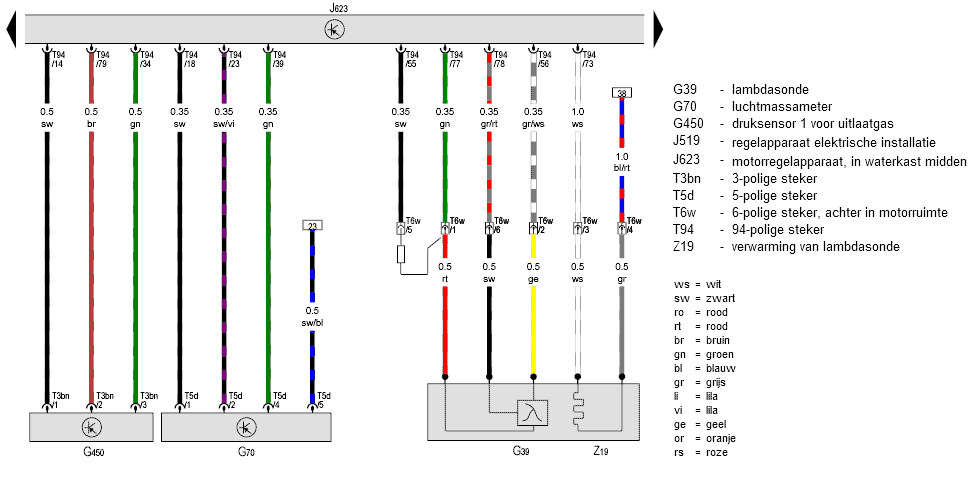

The diagram below of a Volkswagen Golf 6 2.0 TDI indicates the digital mass air flow sensor with component code G70.

- Pin 1 of the mass air flow sensor is connected to pin 18 of the engine ECU. This is the signal wire through which the mass air flow sensor sends the measured value to the ECU;

- Pin 2: signal wire of the intake air temperature sensor. This sensor is integrated into the mass air flow sensor housing;

- Pin 4: ground;

- Pin 5: is connected in the diagram via reference 23 to a fuse. The mass air flow sensor is powered with a voltage of 12 volts.

On pin 1 of the mass air flow sensor, we can measure the signal sent to the ECU. Also, if a breakout box is available, we can verify whether this signal is also correctly received at pin 18 of the ECU. If these signals differ, we can measure the voltage difference across this wire (pin 1 of the MAF relative to pin 18 of the ECU).

A low supply voltage to the sensor can affect the sensor signal. Therefore, we should also check the positive and ground connections. Connect the voltmeter or oscilloscope to pins 4 and 5 and check if we measure a voltage approximately equal to the battery voltage. In the case of a low voltage, there might be a transition resistance in the positive or ground wire, which can be tracked using the V4 measurement.

Reading Values Using Diagnostic Equipment:

The engine management system calculates the amount of air based on the sensor value. Using readout equipment, the current amount of intake air can be read out via live data (also known as parameters or measuring blocks). It does not matter whether the signal is analog or digital; when reading out, you see the value processed by the ECU from the incoming signal.

To check whether the measured value is correct, it can be compared to the factory data. However, these are not easily found in most cases. Therefore, calculators are available to calculate the air amount. A well-known program is the LMM-tool that you can download here.

The value you calculated and the readout value should reasonably match. A slight difference is naturally allowed. We always deal with engine characteristics that differ in each engine; think of valve timing, techniques for increasing filling rate such as variable valve timing, a variable intake manifold, etc. However, if these values differ by dozens of grams, a defect in the mass air flow sensor is not excluded.

The tables below show the calculated values of a naturally aspirated engine with a cylinder capacity of 2000 cc (2.0 liters). We start with an idle speed; this is approximately 800 RPM. A vacuum exists in the intake manifold because the throttle is almost fully closed. The pressure is 0.3 bar. The next two columns show the values at increased engine speed and a fully opened throttle (Wide Open Throttle). Here, the absolute ambient air pressure prevails in the intake manifold, thus 1000 mBar. The intake air temperature rises. The engine speed continues to rise to 6000 RPM.

Situation:

- RPM: 800 RPM;

- Intake manifold pressure: 300 mBar;

- Intake air temperature: 20°.

Calculated Values:

- 3.86 grams/sec;

- 13.88 kg/hour;

- 0.15 grams per stroke.

Situation:

- RPM: 3000 RPM (WOT);

- Intake manifold pressure: 1000 mBar;

- Intake air temperature: 22°.

Calculated Values:

- 47.86 grams/sec;

- 172.31 kg/hour;

- 0.48 grams per stroke.

Situation:

- RPM: 6000 RPM (WOT);

- Intake manifold pressure: 1000 mBar;

- Intake air temperature: 25°.

Calculated Values:

- 94.76 grams/sec;

- 341.14 kg/hour;

- 0.48 grams per stroke.

Consequences of a Defective Mass Air Flow Sensor:

- Reduced power (may not always be noticeable)

- Lower top speed

- Increased fuel consumption

- More soot emissions (diesel engine)

- Engine struggles to reach high RPM under full load

Operation of the Mass Air Flow Sensor:

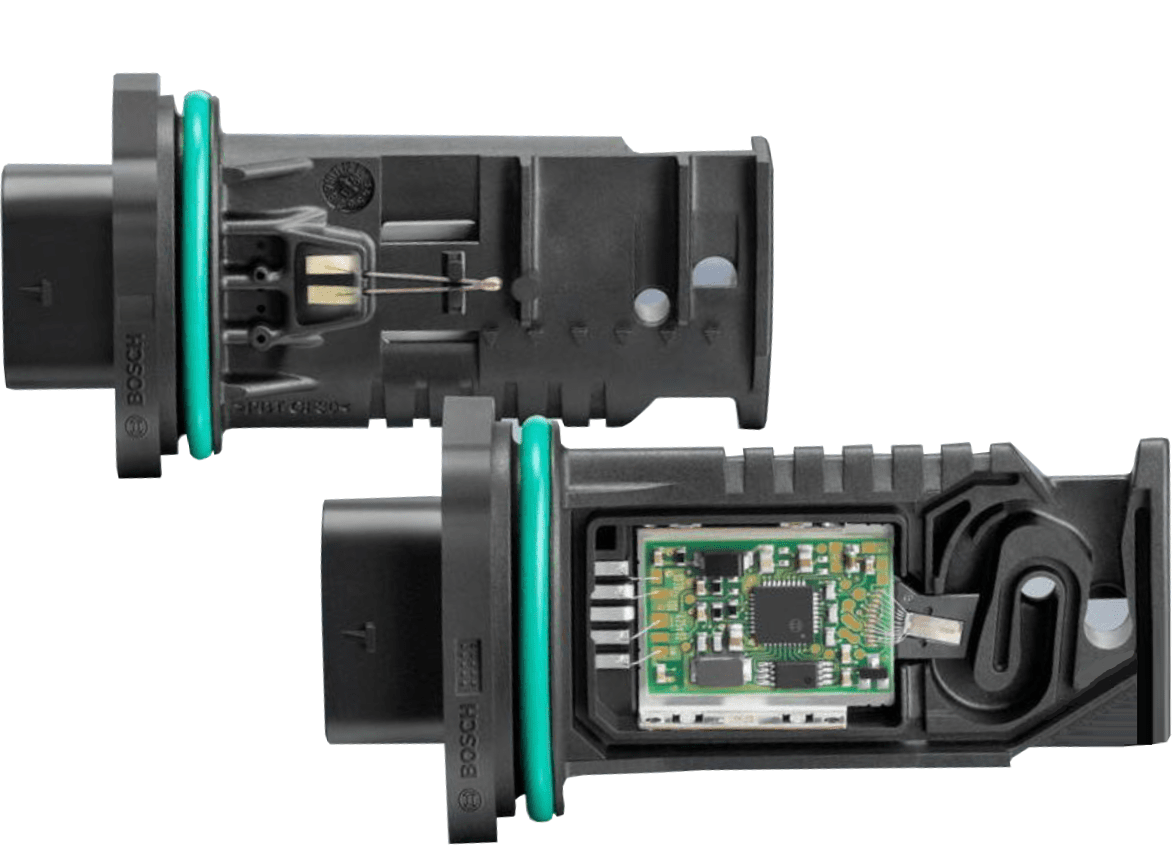

The housing of a mass air flow sensor includes the connector for the wiring harness to the ECU, the electronics on a circuit board, and the measuring element.

The rubber O-ring prevents air from being sucked in around the housing. The measuring element of the mass air flow sensor consists of, among other things, two temperature-dependent resistors (PTC and NTC thermistors).

When the engine is running, the resistors cool down due to the intake air flowing past. The electronic circuit keeps the temperature of the PTC heating element constant. The resulting voltage difference is translated by an amplifier circuit into a usable output signal to be sent to the ECU.

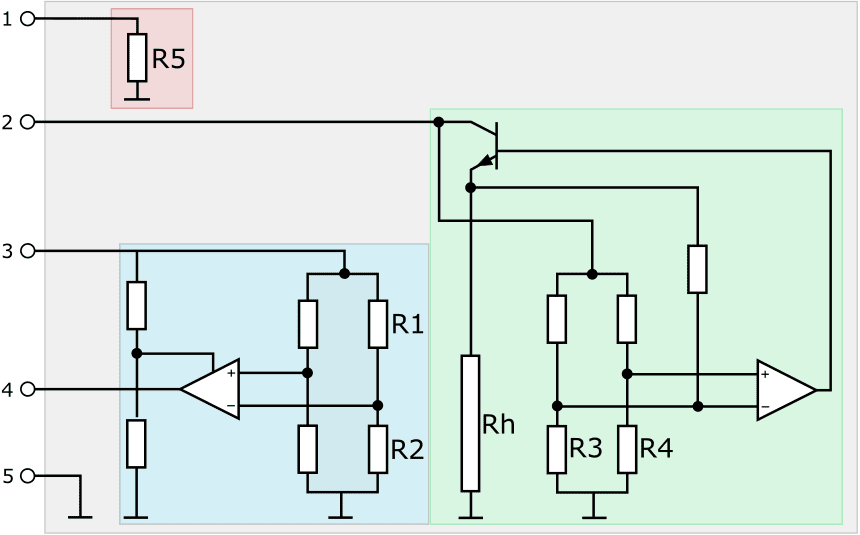

In the following image, the components within the mass air flow sensor are shown in three sub-areas:

- Red: intake air temperature sensor (NTC);

- Green: components for the heating wire;

- Blue: components for the measuring element.

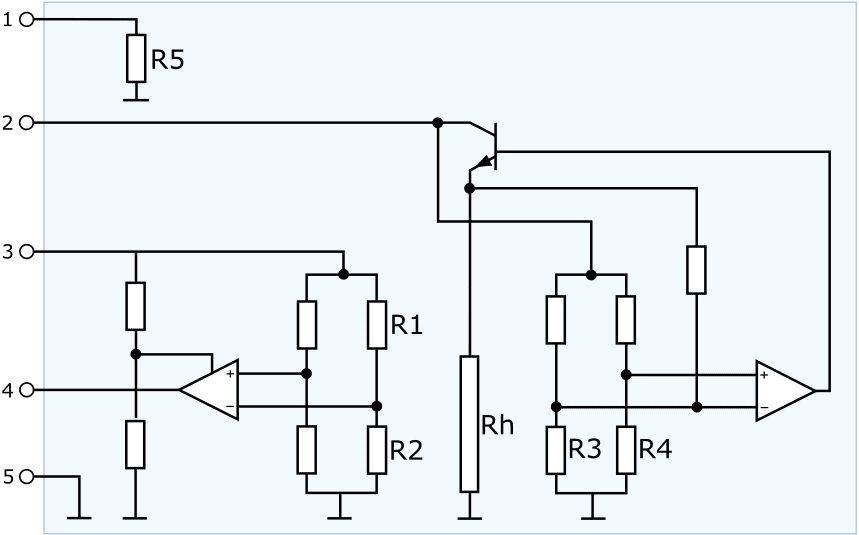

The mass air flow sensor has a 5-pin connector:

- signal of intake air temperature sensor;

- power supply (12 volts) for the heating wire;

- power supply (5 volts) for the measuring element;

- signal (0.5 – 4.5 volts);

- sensor ground. All internal grounds are connected to this output pin.

In the following images, the three sub-areas are shown separately with the corresponding explanation.

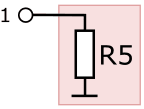

Intake Air Temperature Sensor: as mentioned, this sensor is of the NTC type.

The sensor resistance depends on the air temperature flowing from the air filter, through the mass air flow sensor, to the turbo or intake manifold.

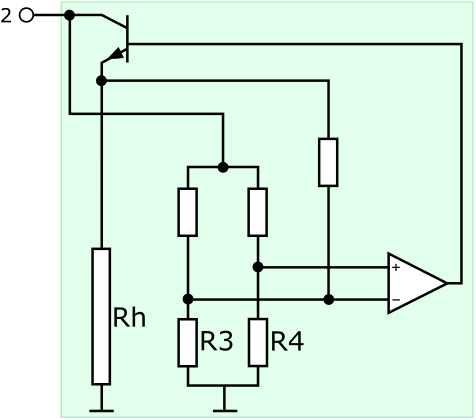

The heated film mass air flow sensor contains a heating resistor that is kept at a constant temperature. In this diagram, the heating resistor is Rh. The heating resistor, also known as the heating wire, is switched on and off by a transistor (at the top).

In the middle, we see a Wheatstone bridge with resistors R3 and R4 at the bottom. These are temperature-dependent resistors (PTC and NTC). Resistors R3 and R4 ensure a constant temperature of heating resistor Rh:

- With an increasing airflow, the resistors cool, and a different voltage drop occurs across all resistors in the bridge. The Wheatstone bridge can convert resistance change into a signal voltage for the ECU. See the “Wheatstone bridge” page for a comprehensive explanation of this circuit.

- Due to the voltage difference on the op-amp, the output voltage to the transistor changes;

- The transistor is activated and switches the power supply to the heating resistor Rh on or off;

- The heating resistor will be kept at the same temperature as much as possible by the power supply.

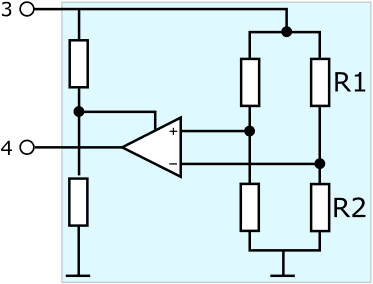

- On both sides of heating resistor Rh, temperature-dependent resistors R1 and R2 are placed;

- If no air flows through the sensor, resistors R1 and R2 have the same value, and there is no output signal;

- If air does flow through the sensor, resistor R1 cools, and R2 is heated;

- As a result, the resistance value of R1 decreases and that of R2 increases;

- As the resistance value increases, the output voltage also rises;

- If the air flows back over the sensor (backflow), R2 cools, and R1 is heated, causing the output voltage to drop. The average output voltage is, therefore, an accurate measure of the amount of air mass flowing towards the engine.

Backflow is the backward flow of air (pulsations) towards the air filter due to the closing of the intake valves or the throttle valve. The backflow is measured as additional air mass, causing a significant deviation in the signal. Modern mass air flow sensors have backflow compensation, as illustrated with resistors R1 and R2 in this example.