Introduction:

The moving parts in the engine must be constantly lubricated while running. If the lubrication is insufficient, for example due to a malfunction in the oil pump, severe internal contamination, or an excessively low oil level, friction occurs. Friction means that parts make direct contact with each other and there is no oil film present between them. The result is increased noise and wear, which can cause the engine to fail within a very short time. Thus, the lubrication system has one of the most important roles in the entire engine. The lubricating effect is achieved with engine oil.

Construction and operation of the lubrication system:

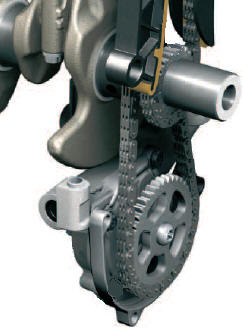

The oil pump supplies engine oil to the components in the engine block. The oil pump is mounted at the bottom of the engine block and, unless the engine is equipped with a dry sump system, often hangs partially or entirely in the oil pan. The oil pump is driven via a chain or gears that are directly connected to the crankshaft. The image shows how the oil pump (through the lower gear) is driven by the crankshaft.

When the crankshaft turns, the gear of the oil pump is driven by the chain. The pump will rotate internally and suck oil from the oil pan. Before the oil enters the oil pump, it first flows through a screen. This screen retains coarse dirt particles. This screen is also directly visible when the oil pan is removed.

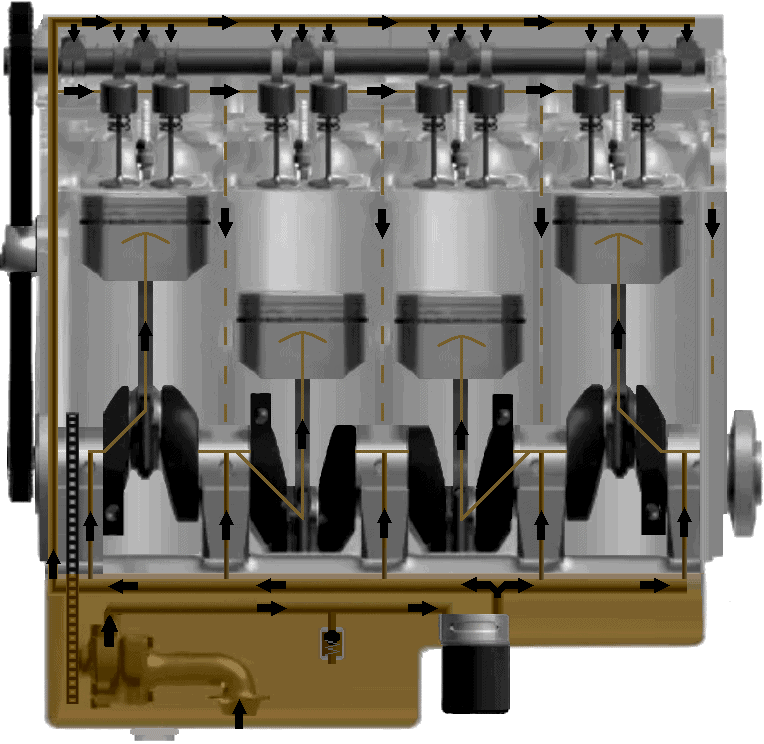

The oil is forced through the pump and then through the oil filter. From the oil filter, the oil is distributed through various oil channels. Several oil channels lead to the crankshaft to lubricate the connecting rod bearings. The oil is also delivered through the connecting rod to the piston. The oil impacts the bottom of the piston, facilitating heat dispersion from the piston. The warm oil then falls back down into the oil pan. This is shown in the image below.

One or more oil channels also lead to the cylinder head. There the oil is evenly distributed over parts such as the camshafts. Due to the holes in the line, each part of the camshaft receives enough oil to be lubricated.

From the cylinder head, multiple return channels run back to the oil pan. Oil also flows through these when the oil is topped up by a person. The oil slowly descends into the oil pan via these return channels.

In addition to the oil channels, various coolant channels are visible when the cylinder head is removed. The oil and coolant channels run closely alongside each other.

Cooling:

The image above shows that the piston is cooled by the oil delivered through the connecting rod. At the top of the connecting rod, holes are present to lubricate the piston pin in the “small end” or “top rod eye.” From this spot, oil is also sprayed on the underside of the piston.

There are also other ways to cool the piston, such as using a hole in the connecting rod foot or a separate oil spray nozzle. This nozzle is depicted in the image. Through this hole in the connecting rod or the oil spray nozzle, an oil jet is sprayed against the underside of the piston.

Dry sump system:

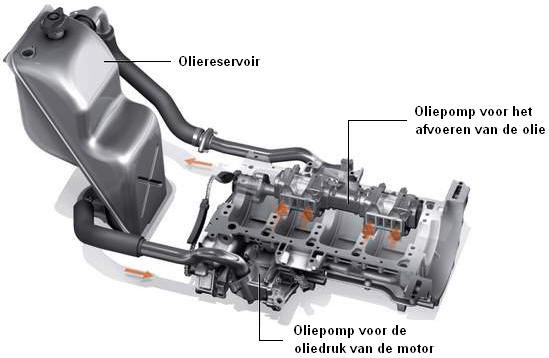

A dry sump system is a component of the lubrication system where the engine is not equipped with an oil pan. In motorcycles, race, and rally cars, the engine block is mounted as low as possible above the road surface to achieve an optimal center of gravity, which also positively affects the vehicle’s aerodynamics by removing the engine as an obstacle in body design. The oil pan limits possibilities due to its size. Other advantages include preventing oil sloshing in the oil pan caused by g-forces and offering better cooling opportunities for the oil.

An external oil reservoir is used to catch the oil. To pump the oil from the engine to the reservoir and back to the engine, two oil pumps are utilized.

The oil pump responsible for moving the oil from the engine to the reservoir needs to have a greater capacity, as there is often a significant amount of air being sucked from the engine as well.

The dry sump system also has disadvantages. It is quite costly due to the structural changes in the engine block and the system components. The biggest disadvantage is the increased risk of air being present in the engine oil. When the circulating oil contains air bubbles, this results in bearing damage to, among others, the crankshaft and connecting rod bearings.