Subjects:

- General

- Construction and function of the lubrication system

- Cooling

- Dry sump system

General:

The moving parts in the engine must be constantly lubricated while running. If the lubrication is insufficient, for example due to a defect in the oil pump, serious internal contamination or an oil level that is much too low, friction occurs. Friction means that parts make direct contact with each other and there is no oil film between them. The result is that extra noise and wear are created, causing the engine to malfunction within a very short time. The lubrication system therefore has one of the most important tasks in the entire engine. The lubricating effect is obtained with engine oil.

Construction and function of the lubrication system:

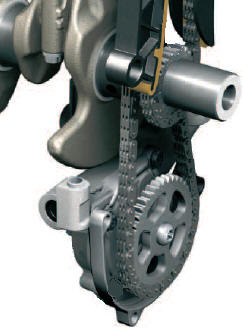

The oil pump supplies engine oil to the components in the engine block. The oil pump is mounted at the bottom of the engine block and, if the engine is not equipped with a dry sump system, often hangs partly or completely in the sump. The oil pump is driven by a chain or gears that are directly connected to the crankshaft. The picture shows how the oil pump (by means of the lower gear) is driven by the crankshaft.

The moment the crankshaft turns, the gear of the oil pump is driven by the chain. The pump will rotate internally and suck the oil out of the sump. Before the oil enters the oil pump, it first flows through a sieve. This sieve stops the coarse dirt particles. This strainer is also immediately visible when the oil sump is disassembled.

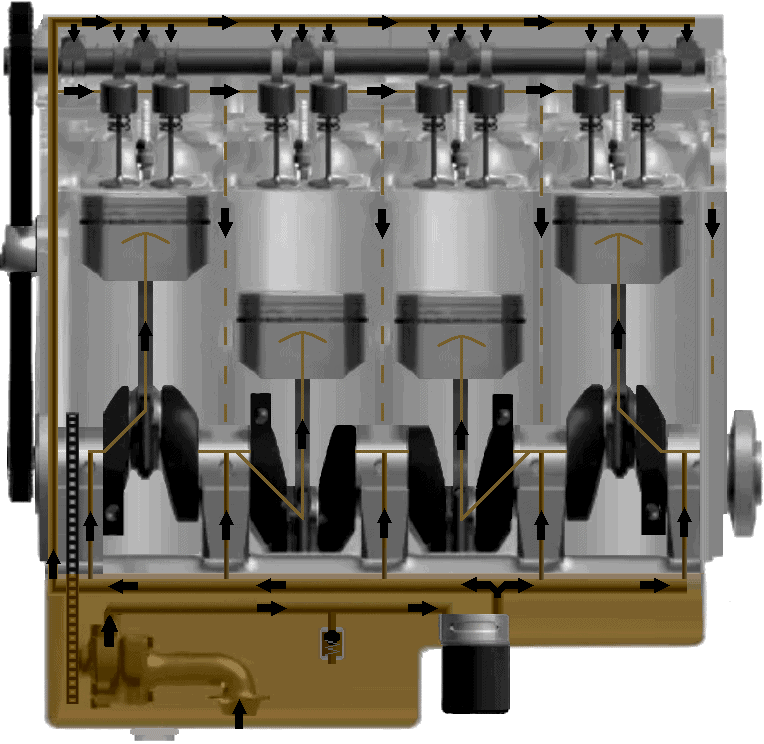

The oil is pumped through the oil filter squeezed out. The oil spreads from the oil filter through various oil channels. A number of oil channels go to the crankshaft, so that the connecting rod bearings are lubricated. The oil is also fed to the piston through the connecting rod. The oil collides with the bottom of the piston. This ensures that the piston can dissipate its heat. The warm oil falls back down into the sump. This can be seen in the image below.

One or more oil channels also run to the cylinder head. There the oil is evenly distributed over, among other things, the camshafts. Because there are holes in the pipe, there is enough oil to be lubricated at all parts of the camshaft.

Several return channels run from the cylinder head to the sump. The oil also flows through this when the oil is topped up by a person. The oil slowly sinks to the sump pan via these return channels.

In addition to the oil channels, various coolant channels are also visible when the cylinder head is removed. The oil and coolant channels run close to each other.

Cooling:

In the picture above you can see that the piston is cooled by the oil supplied by the connecting rod. At the top of the connecting rod are holes to lubricate the gudgeon pin in the “small end” or the “upper connecting rod eye”. Oil is also sprayed on the underside of the piston from this spot.

There are also other ways to cool the piston, namely through a hole in the connecting rod base or a separate oil jet. This nozzle is shown in the picture. Through this hole in the connecting rod or oil nozzle, a jet of oil is sprayed against the underside of the piston.

Dry sump system:

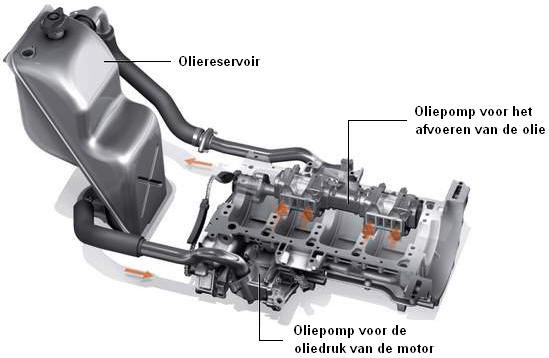

A dry sump system is a part of the lubrication system, where the engine is not equipped with a sump pan. For motorcycles, racing and rally cars, the engine block is hung as low as possible above the road surface to achieve an optimal center of gravity. It will also have a positive influence on the aerodynamics of the vehicle, because the engine will no longer get in the way when shaping the body. The oil pan limits the possibilities because of its size. Other advantages are that the oil can no longer slosh in the sump as a result of occurring g-forces and that there are better cooling options for the oil.

A separate oil reservoir is used to collect the oil. To pump the oil that has flowed down from the engine to the reservoir, and from the reservoir back to the engine, two oil pumps are used.

The oil pump that is responsible for moving the oil from the engine to the reservoir must have a larger capacity, because often a lot of air is drawn from the engine as well.

The dry sump system also has drawbacks. It is quite expensive due to the structural changes of the engine block and the system components. The main drawback is that there is more chance of air being in the engine oil. If the pumped oil contains air bubbles, this will cause bearing damage to, among other things, the crankshaft and connecting rod bearings.