Introduction:

Injectors spray diesel fuel into the diesel engine; this can be into the swirl chamber in indirect injection engines, or directly into the cylinder in direct injection engines. The injector is mounted in the cylinder head. There are different types of injectors. This page describes the various injectors.

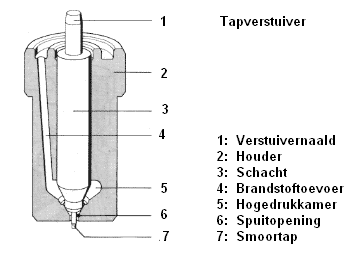

Single-hole injector:

Single-hole injectors are used in diesel engines with indirect fuel injection. The fuel is sprayed into a separate space; namely the pre- or swirl chamber. In this space, the fuel is mixed with the air, resulting in a combustible mixture. The single-hole injector has one injection opening. The injector needle is lifted at a certain fuel pressure, creating a fuel atomization from the injection opening. The opening pressure of single-hole injectors ranges from 100 to 135 bar.

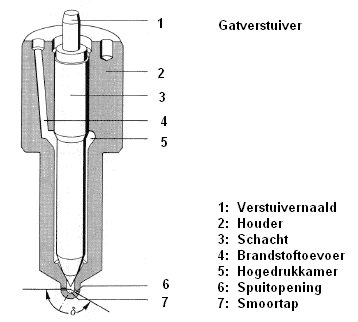

Multi-hole injector:

Multi-hole injectors are used in diesel engines with direct fuel injection. The injector has multiple injection openings that spray the fuel directly into the cylinder. The combustion chamber of these engines is located in the piston crown. The placement of the injection openings is precisely matched to the shape of the combustion chamber. Due to this construction, the injector can only be mounted in one way in the cylinder head. The opening pressure of this injector ranges from 180 to 250 bar.

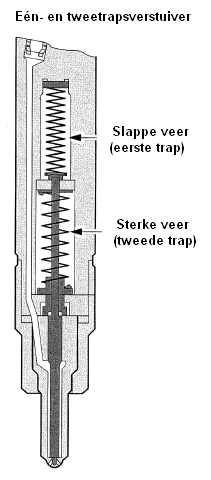

Two-stage injector:

Diesel engines with direct fuel injection have a relatively hard diesel knock. This is due to the rapid pressure increase in the cylinder caused by the large amount of fuel injected at once.

By using the so-called pre-injection, combustion is initiated gently. As a result, the diesel knock is significantly reduced.

Some manufacturers equip their engines with these so-called two-stage injectors. These are multi-hole injectors, but with two springs; namely a stronger spring and a weaker spring. The weaker spring allows the needle to lift slightly at a lower pressure. This results in a small amount of fuel being sprayed into the cylinder at low pressure; the pre-injection. This initiates the combustion. The injector needle hits a stop that is backed by the strong spring. The pressure will further increase to the normal opening pressure. The needle will then open maximally: the main injection.

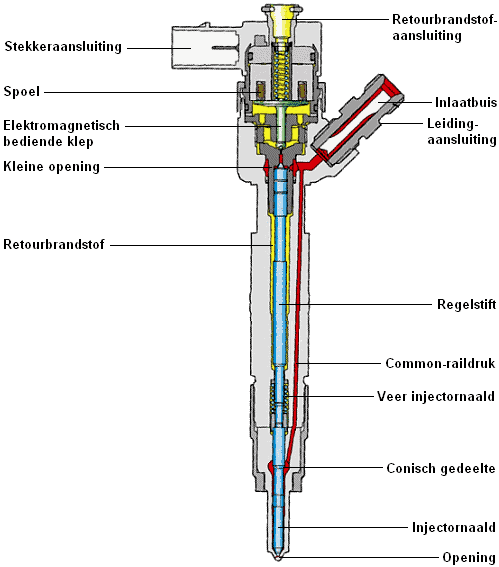

Electromagnetically actuated injector:

Electromagnetically actuated injectors are used in common rail diesel engines. The injector is actuated by an electromagnet. The engine management determines when the injector should open and close and how long it should remain open based on the engine speed, the throttle position, the temperature, the load, and the engine position. In the rest position, the injector is not actuated. The common rail pressure, which can reach up to 1300 to 2000 bar (depending on the diesel engine generation), continuously prevails on the inlet pipe of the injector.

When the engine management sends a signal to the injector, the coil is energized, and the electromagnetically controlled valve is pulled upward. The fuel pressure above the control rod is diverted via a small opening back into the other return fuel line. This causes the fuel pressure above the control rod to drop very quickly. The control rod will move upwards, aided by the conical section located at the bottom of the control rod. The control rod, and thus the injector needle, is raised. At that moment, the opening at the bottom of the injector is cleared, allowing the fuel at the common rail pressure, up to 1300 bar, to be injected into the combustion chamber.

With electromagnetically actuated injectors, there is no need for two springs for the pre- and main injection. The electromagnetically actuated injector can be actuated multiple times in a row. The duration of the pre- and main injection can also vary depending on the operating conditions of the engine. It is also possible for this injector to perform two main injections. The advantage of multiple injections is a smoother combustion process.

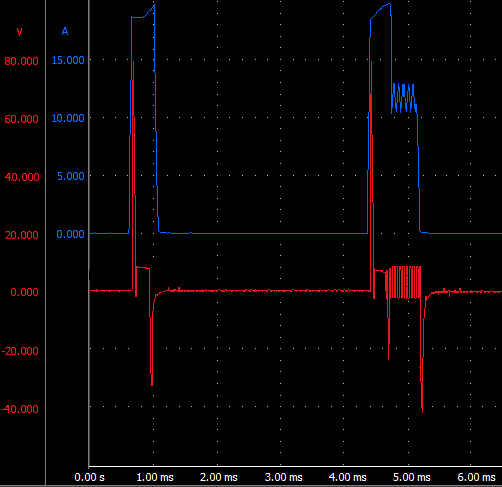

Peak and hold:

The electromagnetically actuated injector is energized with the electromagnetic coil. When the current through the coil is high enough, the electromagnet overcomes the spring force on the valve. To move the injector needle, a short current and voltage peak are required. The onboard voltage of 14 volts is insufficient to lift the needle from its seat. Within a time frame of only 0.3 nanoseconds (10^-9 seconds), the coil is energized with 20 Amperes at 80 volts (peak). After the injector needle has opened, it is held open with 12 Amperes at 14 volts (hold), until the actuation stops and the needle is pressed back onto its seat by the spring force.

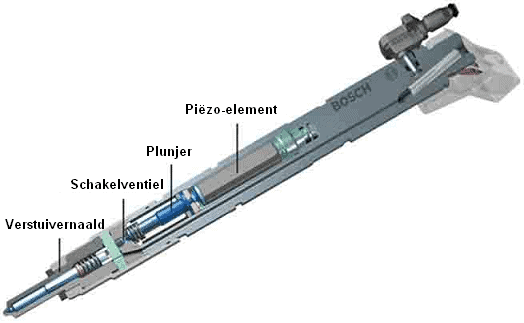

Piezo injector:

Piezo injectors are used in both gasoline and diesel engines.

The element in a piezo injector becomes longer or shorter as the applied voltage changes. The length change is only thousands of millimeters, which is too little to sufficiently open the injector needle. Therefore, multiple piezo crystals are connected in series, allowing the injector needle to make a larger stroke.

The image shows what happens to the piezo element when the applied voltage is increased.

The actuation voltage of a piezo injector ranges between 100 and 160 volts. This voltage is achieved using capacitors in the engine control unit. The current is only a few milliamperes. With this voltage and current, the total length change of the piezo element is about 0.08 millimeters. The closing of the injector needle occurs by briefly reversing the current direction.

The advantage of the piezo injector compared to an electromagnetic injector is that it switches approximately five times faster. As a result, the system can be controlled more precisely, has a faster response time, and can inject more frequently per working cycle.

Unit injector:

Volkswagen has used unit injectors for some time. The operation is complex and is therefore described on a separate page. Click here to go to the page about the unit injector.