Introduction:

When fossil fuels are burned, carbon dioxide (CO2) is released. This CO2 accumulates in the atmosphere. When sunlight hits the earth, the accumulation of CO2 prevents the heat radiation from escaping, creating the ‘greenhouse effect’. 120g CO2/km is equivalent to:

- 5.2 liters of gasoline/100 km

- 4.5 liters of diesel/100 km

- 4.4 kg of natural gas/100 km

- 1.0 kg of hydrogen/100 km

- 20 kWh electricity/100 km

Hybrid technology reduces CO2 emissions. Manufacturers are currently busy developing more and more technologies to achieve an energy transition to CO2-neutral driving.

Vehicles with hybrid drive use both the internal combustion engine and an electric motor. The goal of hybridization is primarily to reduce fuel consumption and exhaust emissions. Additional benefits thanks to the electric motor(s) include higher torque and more comfort.

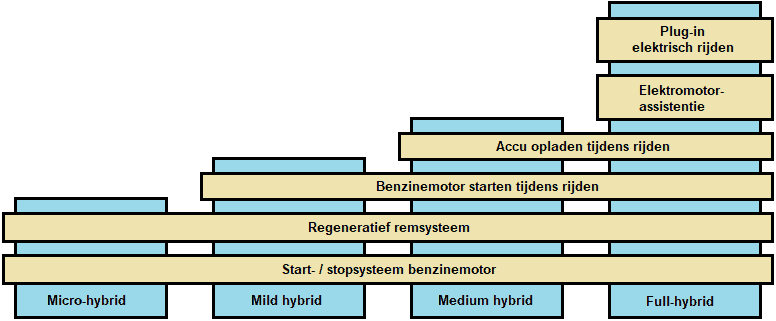

In hybrid drives, a distinction is made between Micro-hybrid, Mild-hybrid, and Full-hybrid vehicles.

A vehicle with full electric drive does not fall under the “hybrid” category. A vehicle equipped with a range extender can be classified under the “series hybrid” category.

The diagram below shows the different hybrid forms from a low to a high degree of electrical support or drive.

Micro Hybrid:

A micro-hybrid vehicle does not have an electric motor to support the internal combustion engine while driving, but is equipped with various fuel-saving technologies. Therefore, there is no HV (High Voltage) system. Fuel savings are achieved through the start/stop system, which automatically shuts off and starts the engine when the vehicle is stationary, and an energy recovery system for the battery. This recovery system maximizes alternator charging when the vehicle decelerates. The energy that is usually lost in the brake pads is now partially used to charge the 12-volt battery. Therefore, when driving at a constant speed, no extra fuel injection is needed for the increased load on the alternator, resulting in fuel savings.

Mild Hybrid:

In Mild-hybrid vehicles, the combustion engine is supported by one or two 48-volt electric motors that provide extra power under different operating conditions. The electric motor assists the internal combustion engine during acceleration. When driving at a constant speed, the electric motor is automatically switched off again. The vehicle cannot drive entirely electrically.

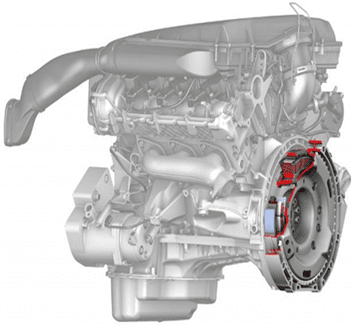

The electric motor is located near the flywheel, or there is a chain/belt drive between the electric motor and the end of the crankshaft. The relatively compact 48-volt battery is usually located in the trunk.

An image shows the electric motor in the flywheel housing of the internal combustion engine. Here too, there is no HV system. Therefore, a technician without NEN certification may perform work on the electric drivetrain.

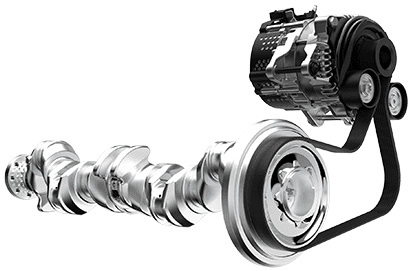

A micro-hybrid vehicle may also be equipped with a 48-volt starter-generator, which is essentially a combination of an alternator and a starter motor. Manufacturers give the following names to this type of starter-generator:

- Dynastart;

- Starter generator;

- Belt driven starter-alternator;

- Belt integrated starter-generator (BSG).

Using a mechanism, the multi-belt can be tightened on the appropriate side depending on charging or starting.

The following three images show the three possible positions during regenerative battery charging, starting the internal combustion engine, and the electric motor mode, where it supports the internal combustion engine. Support for turbo engines mainly occurs in the low RPM range, where the “boost” of the electric motor compensates for the so-called turbo lag.

A 48-volt starter-alternator replaces the “ordinary” 12-volt alternator. In addition to the 48-volt battery, there is also a 12-volt battery for the on-board network, which supplies energy to the lights, door locks, and accessories in the car. A DC-DC converter converts 48 volts to 12 volts to charge the battery.

Series Hybrid:

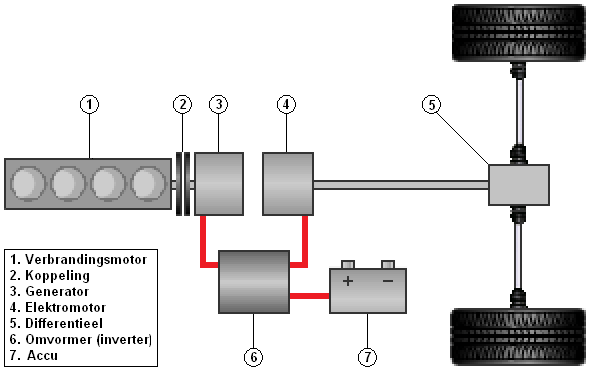

A vehicle with series hybrid drive is solely powered by the HV electric motor. There is no direct connection between the internal combustion engine and the wheels. The image below shows an example of a rear-wheel-drive series hybrid car.

A coupling (2) exists between the internal combustion engine (1) and the generator (3). When the engine runs and the coupling is closed, the HV battery (7) is charged by the generator (3) and the inverter (6). The inverter regulates the AC voltage supplied by the generator to a controlled DC voltage.

The electrical components in a series hybrid drivetrain operate at high voltage (HV). This is identified by orange cables and connectors. Only certified technicians may work on the HV system.

Advantages of the series hybrid system:

- Simple construction as the internal combustion engine does not directly drive.

- Suitable for full electric driving if the battery is large enough.

- No clutch needed for starting from a standstill; the electric motor does this.

- No reverse gear needed as the electric motor can rotate in two directions.

- Can be charged via the grid (plug-in).

Disadvantages:

- The electric motor must provide all drive power

- Heavier than a vehicle with parallel drive.

Parallel Hybrid:

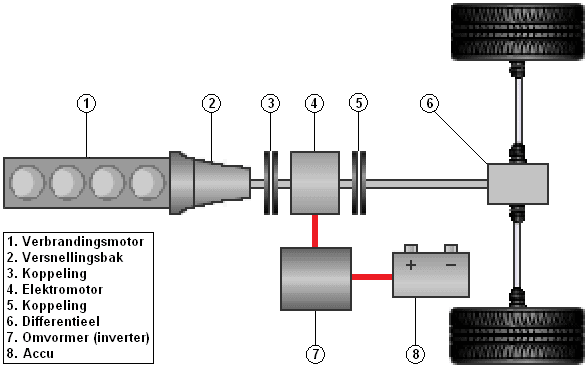

In a vehicle with parallel hybrid drive, there can be a direct connection between the internal combustion engine and the wheels. When the couplings (3 and 5) in the image below are closed, the vehicle can drive on the internal combustion engine. The electric motor (4) is used for both charging the battery and driving the wheels.

A parallel hybrid can also drive using only the electric motor. By opening coupling 3, the connection with the internal combustion engine is broken; it can be switched off, allowing pure electric driving. Clutch 5 is coupled when pulling away from a standstill.

Like the series hybrid, the parallel hybrid has an HV installation with orange cables and connectors.

Advantages of the parallel hybrid system:

- Suitable for full electric driving, if the battery is large enough and there is a coupling between the internal combustion engine and electric motor.

- No reverse gear needed as the electric motor can rotate in both directions.

- Can be charged via the grid (plug-in).

- Smaller internal combustion engine since the electric motor assists during acceleration.

- Smaller electric motor since the internal combustion engine can assist during acceleration.

- Lower mass than a vehicle with series drive.

Disadvantages:

- Mechanically complex.

- Clutch needed for electric take-off.

- Transmission needed.

Plug-in Hybrid:

The battery of a hybrid vehicle is normally charged through regenerative braking, or by letting the internal combustion engine drive the electric motor (then used as a generator). The latter is, of course, not efficient.

With a plug-in hybrid, the battery pack can be charged by connecting the vehicle with a plug at home using a socket or a public charging station and charging it with the power grid. When you leave with the car, the first kilometers can be covered electrically (thus emission-free). Ideal when driving from the city to the highway. When SOC (State Of Charge), or the battery state of charge, becomes low, the internal combustion engine will start and provide the main drive. During deceleration, the battery will be partially recharged using regenerative braking.

An additional advantage is that the electric auxiliary heater and/or air conditioning can be programmed for a preset time, allowing comfortable interior conditions without compromising battery capacity or fuel.

A plug-in hybrid typically has a limited electric range of 40 to 60 km. Examples include:

- BMW 225XXE Active Tourer (2021): 55 km;

- Hyundai Ioniq (2021): 52 km;

- Mitsubishi Outlander PHEV model year 2015: 43 km and model year 2021: 54 km;

- Volkswagen Passat GTE Business plug-in hybrid (2021): 55 km.

Note: these are manufacturer specifications. In unfavorable conditions, such as low temperatures or an unfavorable driving style, the range can drop by up to 30%.

Energy Recovery:

During acceleration, the battery supplies electrical energy to the electric motor. At the moment of deceleration (braking), the electric motor will operate in a generating mode; the electric motor will then charge the battery. This is also known as “regenerative braking” or “recuperative braking.” You can find more information on the inverter and the electric motor pages.

System Overview Toyota Prius:

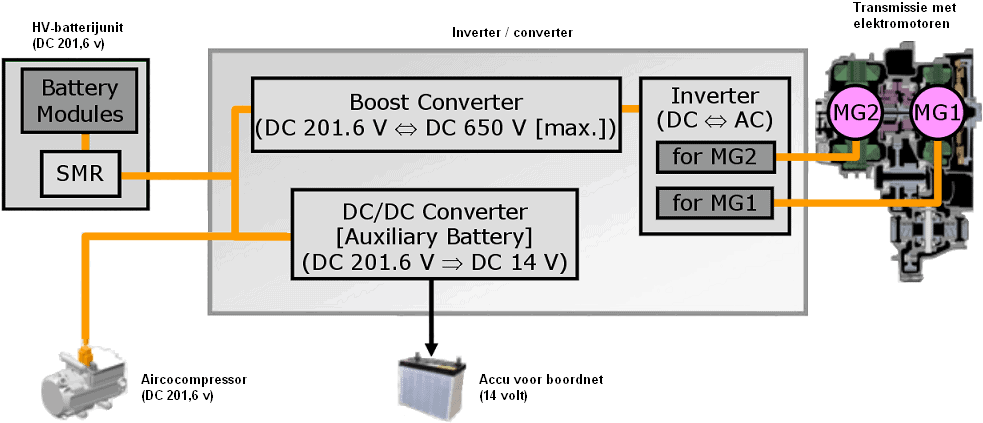

The battery of a Toyota Prius stores around 200 volts DC. The boost converter converts the battery voltage of 201.6 into a higher DC voltage of 650 volts. The boost converter is a DC/DC converter; it remains direct current, only the voltage is increased. The 650-volt direct current reaches the inverter. The inverter converts direct current (DC) to alternating current (AC) and vice versa. Hence, we call this converter an AC/DC rectifier or DC/AC converter. In addition to converting DC to AC, the inverter also controls the electric motors using IGBTs. The two electric motors (MG1 and MG2) operate with three-phase alternating current of approximately 600 volts.

The battery voltage not only goes to the boost converter and the AC compressor but also to the DC/DC converter for the on-board battery. The voltage of 201.6 volts is reduced to 14 volts to charge the lead-acid battery. The 14-volt battery is connected to the vehicle’s interior and exterior electrical components, such as the radio, lighting, door locks, etc.

System Overview Mitsubishi Outlander:

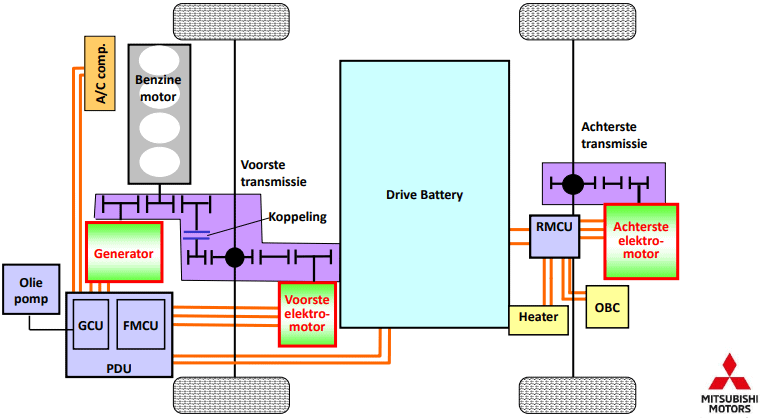

The following overview shows the components of a Mitsubishi Outlander (model year 2019 >).

This (plug-in) hybrid behaves, depending on driving conditions, as an EV, series hybrid, or parallel hybrid. The abbreviations are as follows:

- PDU: Power Drive Unit

- GCU: Generator Control Unit

- FMCU: Front Motor Control Unit

- RMCU: Rear Motor Control Unit

- GCU: Generator Control Unit

- OBC: On Board Charger

EV-mode: when driving fully electrically, the multiple wet plate clutch is disengaged, and the electric motors (each with a maximum power of 60 kW) provide the drive. The gasoline engine and the generator are switched off.

Series mode: when the battery charge is <30% and a power demand of >60% occurs, the gasoline engine and generator start. The clutch remains disengaged. The gasoline engine drives the generator, which charges the battery (and not the wheels). The system now behaves as a series hybrid. The gasoline engine’s RPM is around 1700 rpm while driving. During acceleration and braking, the RPM drops to 1100 rpm.

Parallel mode: when driving faster than 65 km/h, there is an increased power demand, or the SOC of the battery is <30 %, the transmission shifts accordingly, creating the parallel mode. The combustion engine and the front electric motor drive the wheels. Synchronization of the RPMs of the combustion engine and front electric motor occurs before the clutch is engaged. In parallel mode, the rear electric motor is controlled up to 5% to prevent magnetic field resistance when running unloaded at high RPM.

Transmission of a Hybrid Vehicle:

As of 2019, most manufacturers (Ford, Honda, GM) use CVT (Continuously Variable Transmission) technology for their hybrid models.

The CVT technology of the Toyota Prius (see image) is not achieved by a drive belt and adjustable diameter pulleys, but by an electronically controlled combination of an electric motor, generator, and planetary gear system. The advantage of this type of transmission compared to a mechanical CVT is that it is not prone to wear and is significantly lighter.

The Prius’s depicted drivetrain consists of:

- internal combustion engine (petrol engine);

- electric motor MG1 (functions as a generator/alternator during regenerative braking);

- electric motor MG2 (the motor for propulsion);

- planetary gear system (Power Split Device) that can connect and disconnect the internal combustion engine and electric motor from the drivetrain;

- chain drive on gears connected to the differential.