Introduction:

An electric motor is used to drive a hybrid or fully electric vehicle. The electric motor converts electrical energy (from the battery or range extender) into motion to drive the wheels. Additionally, the electric motor can also convert kinetic energy back into electrical energy when braking on the motor: regenerative braking. In this case, the electric motor functions as a generator. Because of these two functions, we also call the electric motor an “electrical machine.”

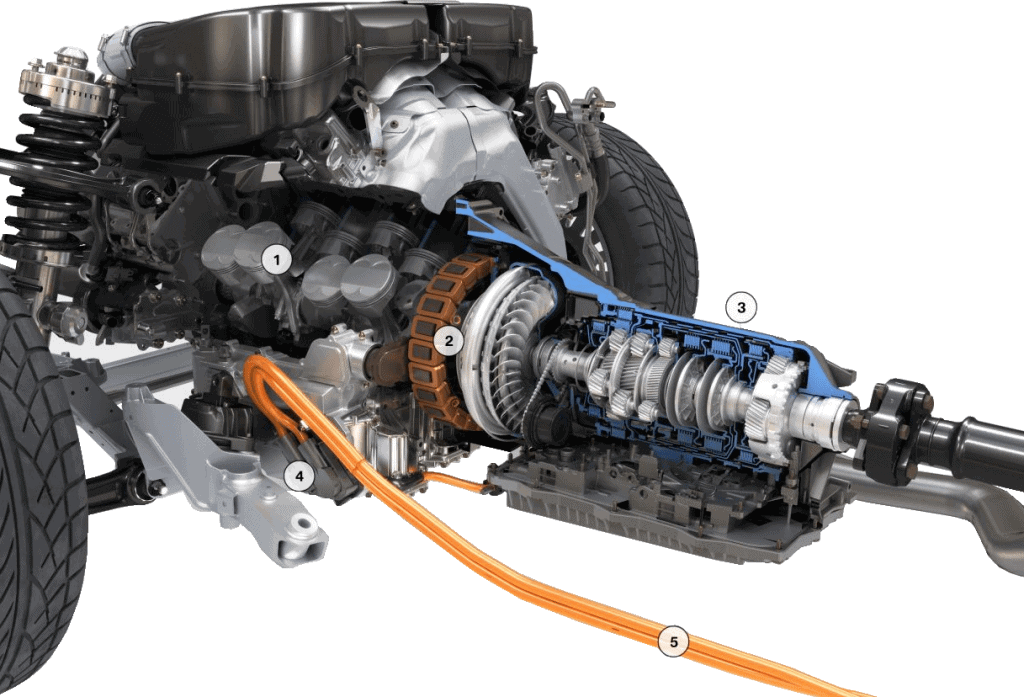

The placement possibilities of the electric motor in a hybrid vehicle are:

- On the internal combustion engine, where the transmission is established via a multi-belt or directly via the crankshaft;

- Between the engine and transmission: the input shaft of the transmission is driven by the electric motor;

- Integrated into the transmission;

- At the differential;

- At the wheel hubs (hub motor).

The electric motor of a fully electric car is often mounted at the rear axle. In the image below, the electric motor with the inverter in a cylindrical housing and the final drive of a Tesla can be seen.

AC Electric Motor (Synchronous, with Permanent Magnets):

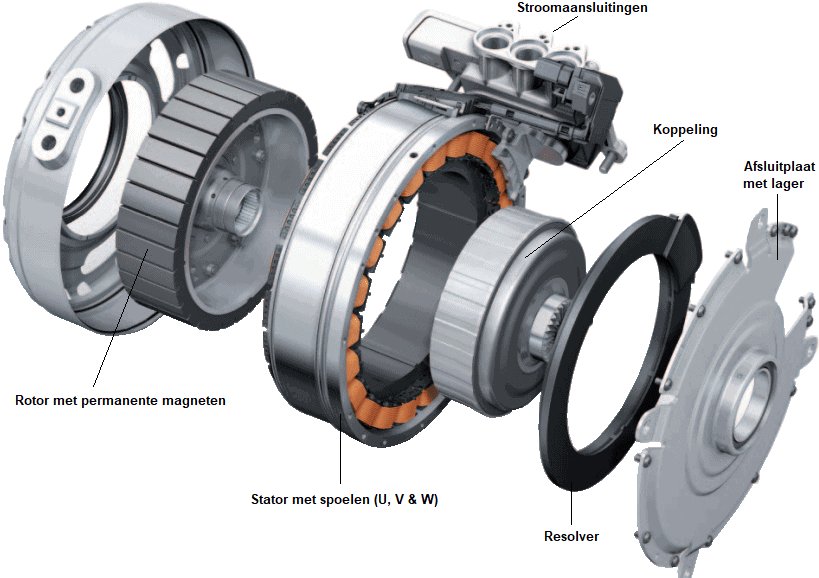

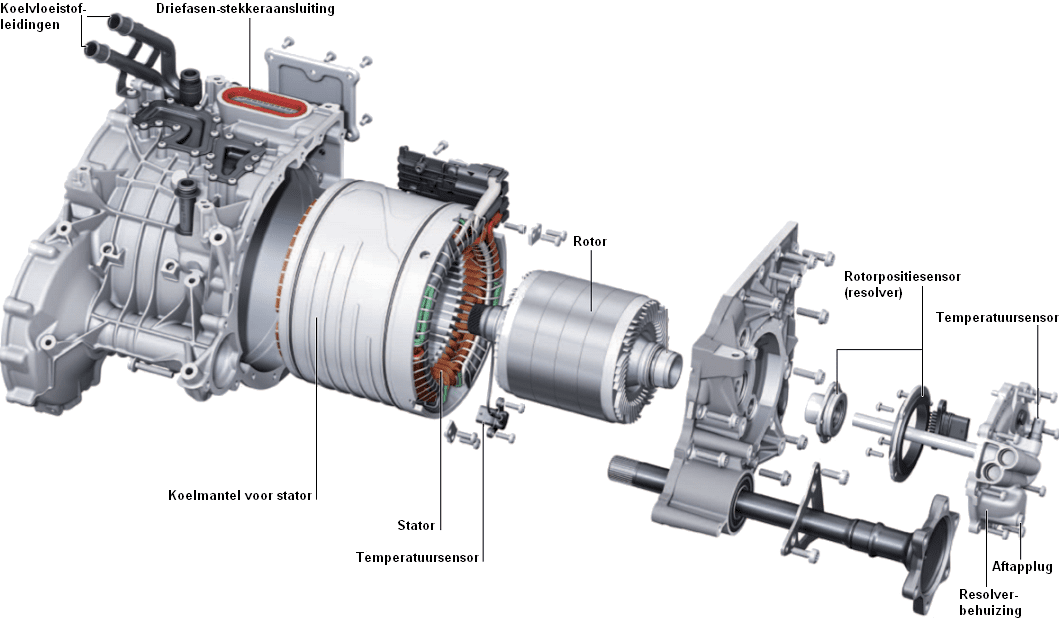

The next image shows the components of a (synchronous) electric motor from an Audi. This type is used in the hybrid variants of the A6 and A8. We will briefly list the components. In the following paragraphs, these components will be described in detail.

The rotor with permanent magnets will rotate as a result of a change in the magnetic field in the stator. The rotor is connected to the coupling, which can connect or disconnect the internal combustion engine and electric motor (in cooperation with an unshown clutch) under different operating conditions. The position of the rotor is measured by the resolver: this data is important for the IGBT drivers to control the stator coils at the right moment.

The electric motor with permanent magnets can be controlled by both a DC (direct current) as well as AC (alternating current).

The synchronous motor is one of the most used electric motors in hybrid or fully electric vehicles. This type of electric motor consists of a stator with windings and a rotor with multiple permanent magnets. The rotor rotates at the same speed as the magnetic field of the stator. The control of the synchronous motor can be realized as follows:

- AC: controlled by a sinusoidal signal (alternating current).

- DC: controlled by a square or trapezoidal signal (direct current)

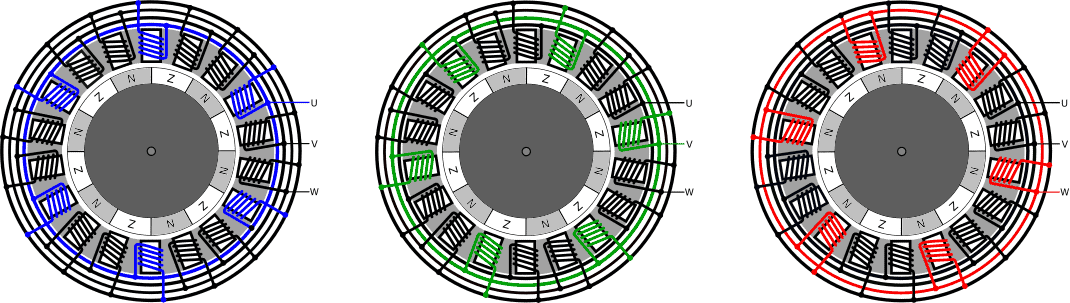

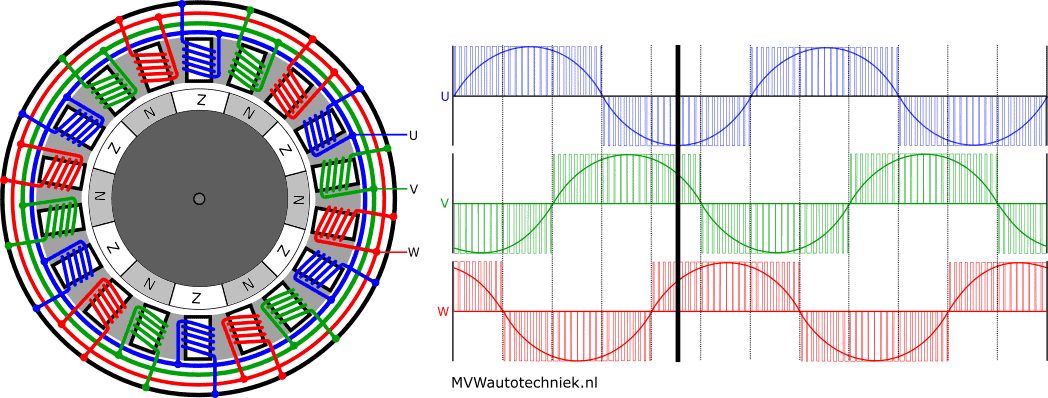

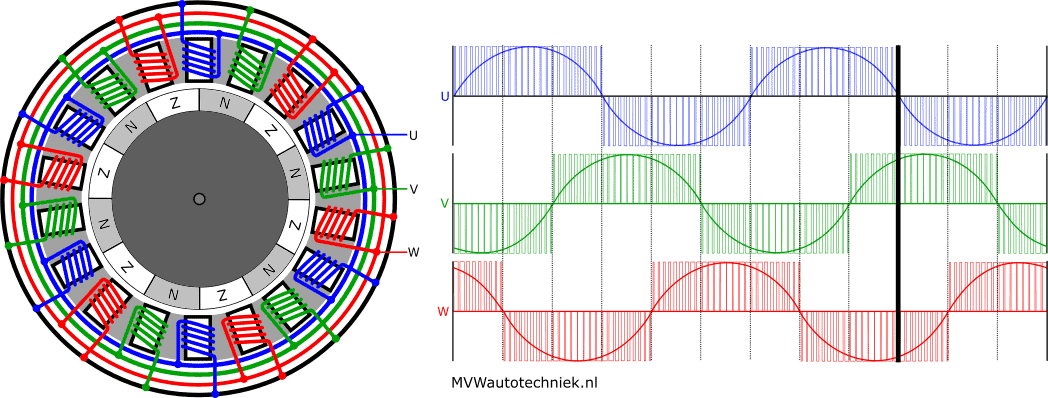

The stator of the synchronous motor is built up of three stator coil groups: U, V, and W. Each group contains three sets of six parallel-connected coils distributed over the entire circumference of the stator. Every third coil belongs to the same series.a0

- U-coils: blue

- V-coils: green

- W-coils: red

The rotor contains multiple permanent magnets. By alternately energizing coils in the stator, a rotating magnetic field is created. The rotor follows the rotating field and thus starts to rotate.

AC Control of the Synchronous Motor:

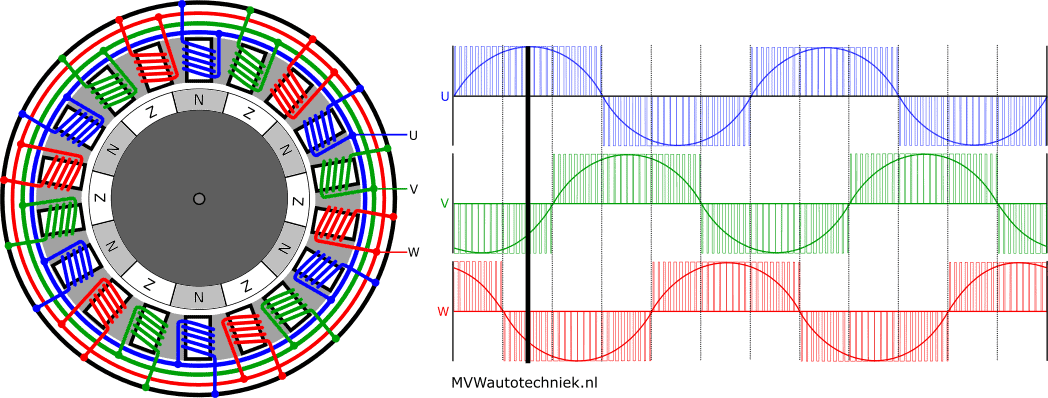

The AC control uses frequency-controlled control or sinusoidal commutation. The stator coils are supplied with a varying three-phase sinusoidal voltage to make the rotor rotate.

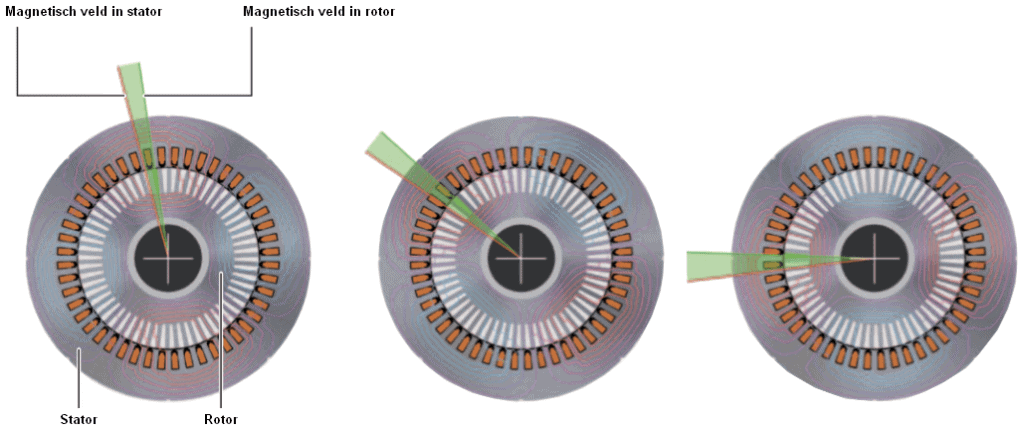

The image below shows the rotor position with a maximally energized U-coil. The north poles have ended up directly opposite the energized U-coils due to the magnetic field. The cursor in the graph next to the electric motor indicates the control of the coils at that moment.

For information: in the explanation, the rotor rotates clockwise when the stator coils are energized.

In the next image, the sine, i.e., the alternating current through the U-coil, is maximally negative. During this control, the south poles of the rotor are directly opposite the energized (U) stator coils.

In reality, there is a small air gap between the north and south poles of the rotor. During the transition from the south to the north pole, the current direction in the U-coil reverses. Further:

- The current through the V-coil (green) is almost maximally positive; the north pole is also almost opposite the coil.

- The current through the W-coil has been maximally negative and is rising. The south pole has rotated past the coil.

To give an impression of how the current flows, the rotor rotation as a result of the alternating current is shown in the animation below.

AC Electric Motor (Asynchronous, Induction Motor):

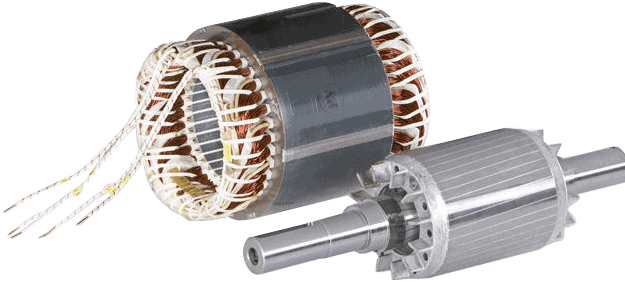

The induction or squirrel-cage motor is an asynchronous motor. The difference with the synchronous motor with permanent magnets and the asynchronous motor lies in the rotor: this is a soft iron drum with conductors in the longitudinal direction. The rotor runs asynchronously with the stator, meaning there is a speed difference between the rotor and the magnetic speed of the stator. The stator is exactly the same.

The rotor of the asynchronous electric motor consists of short-circuited coils; the U, V, and W coils are connected to each other on one side. When the rotor is located in the stator’s rotating field, an induction voltage is generated in the rotor coils. Because the rotor coils are short-circuited, a current will flow. This current causes the rotor to create a magnetic field, thus generating torque. Because the operation of the asynchronous electric motor is based on the induction law, we also call it an induction motor.

The delivered torque influences the slip between the rotating magnetic field in the stator and the rotor’s speed.

The asynchronous motor has several advantages and disadvantages compared to the synchronous motor.

Advantages:

- Relatively simple, robust, and inexpensive rotor;

- High torque at low speed.

Disadvantages:

- Lower power density (per mass) and efficiency. The currents in the short-circuited rotor coils lead to additional rotor losses;

- Speed is not accurately controllable as it depends on the load. This does not necessarily have to be a disadvantage: with a good control system, the speed of the asynchronous motor can also be set;

- High starting current.

The rotor position and speed of the asynchronous motor are measured by a rotor position sensor. Typically, Hall sensors provide a minimum of four pulses per revolution of the rotor to convey the rotor position and speed. We don’t call this type of rotor position sensor a resolver, as is the case with the synchronous motor.

In contrast to the synchronous motor, the rotor position sensor is not needed to know the rotor position when stationary. However, the rotor position is important while rotating: it is necessary to prevent the slip between the magnetic rotating field and the rotor from becoming too large. If the rotating field becomes too fast, a situation can arise where the rotor suddenly wants to rotate the other way. The forces arising from this can be disastrous for the mechanical and electrical components.

Some manufacturers choose to apply a resolver even with an asynchronous motor. The reason for this is unknown to me. The resolver is extremely accurate both when stationary and while rotating, which perhaps enhances precise control.

Efficiency Maps of the Synchronous and Asynchronous Electric Motors:

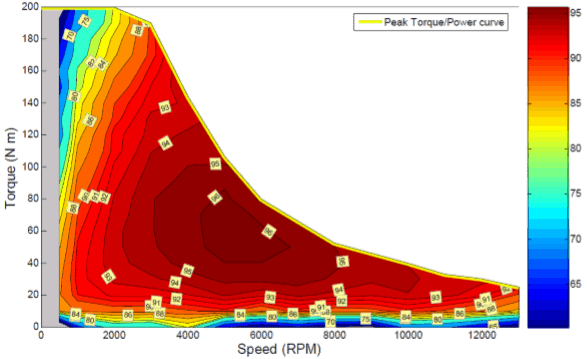

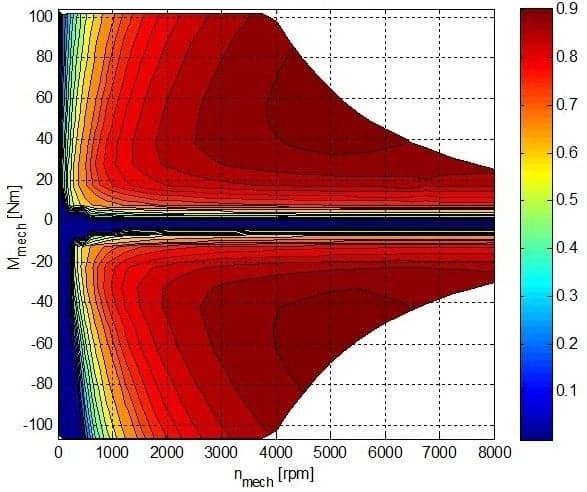

The images below show the efficiency of the synchronous electric motor (left) and the asynchronous electric motor (right).

- The synchronous electric motor is very efficient. The efficiency is above 90% in a large area, with peak values reaching up to 96%. Field weakening occurs from 2000 rpm, reducing the maximum torque.

- The asynchronous motor has a significantly lower efficiency at lower speeds compared to the synchronous motor.

Related Pages: