Direct and indirect fuel injection in gasoline engines:

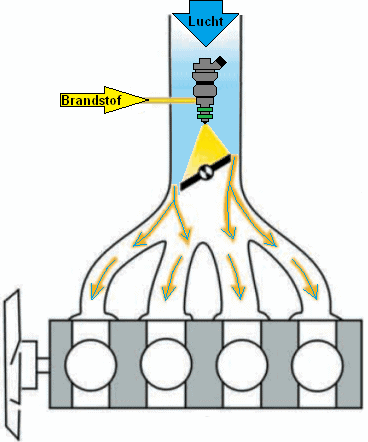

Direct Injection:

In direct injection (DI), the gasoline is injected directly into the combustion chamber instead of the intake. This technique allows the gasoline to be injected after the compression stroke has already started, resulting in better combustion.

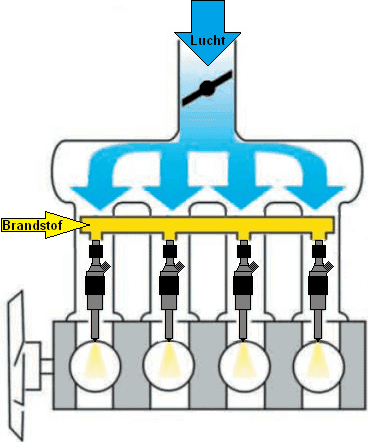

Indirect Injection:

In indirect injection (IDI), the gasoline is injected into the intake and drawn into the engine along with the air. This method can use one injector for all cylinders or provide an injector for each cylinder. In the latter case, the power and emissions reduction potential of the engine increase because the fuel injection can be optimally adjusted per cylinder.

Direct and indirect fuel injection in diesel engines:

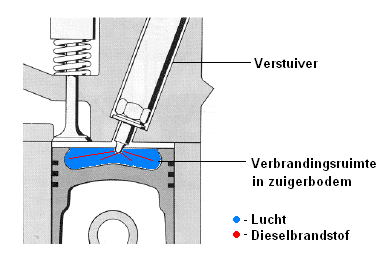

Direct Injection:

The injection pressure in direct injection is higher than in indirect injection. The fuel is injected directly into the cylinder (or the specially formed piston head) at the end of the compression stroke. The mixing thus takes place in the cylinder and not in the swirl chamber as with indirect injection. To improve mixture formation, the intake air is swirled. The swirl is created by the shape of the intake manifold and the shape of the piston head.

A diesel engine with direct injection has the advantage over an engine with indirect injection of having less combustion chamber wall area. As a result, a direct-injected diesel engine will have less compression and combustion heat loss, leading to higher efficiency and cleaner exhaust gases.

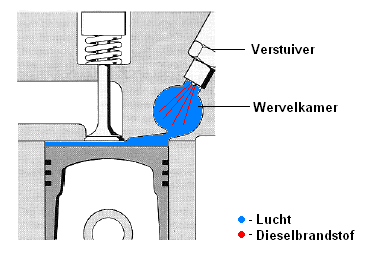

Indirect Injection:

Indirect injection was most commonly used in older diesel engines. Nowadays, it is rarely seen. The fuel is injected, mixed, and vaporized in the swirl chamber, unlike in direct-injected diesel engines where it occurs in the cylinder itself. The fuel is injected into the swirling air of the swirl chamber during the compression stroke. This method provides a good mix of fuel and air.