Introduction:

The differential, also known as the cardan, allows for a speed difference in the drive system. On this page, only the term differential is used.

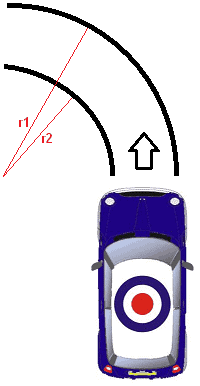

When taking corners, one wheel makes more revolutions than the other wheel. When a car turns left (as shown in the image below), the right wheels will therefore make more revolutions than the left wheels (r1 > r2). A speed difference thus arises. A differential makes this possible.

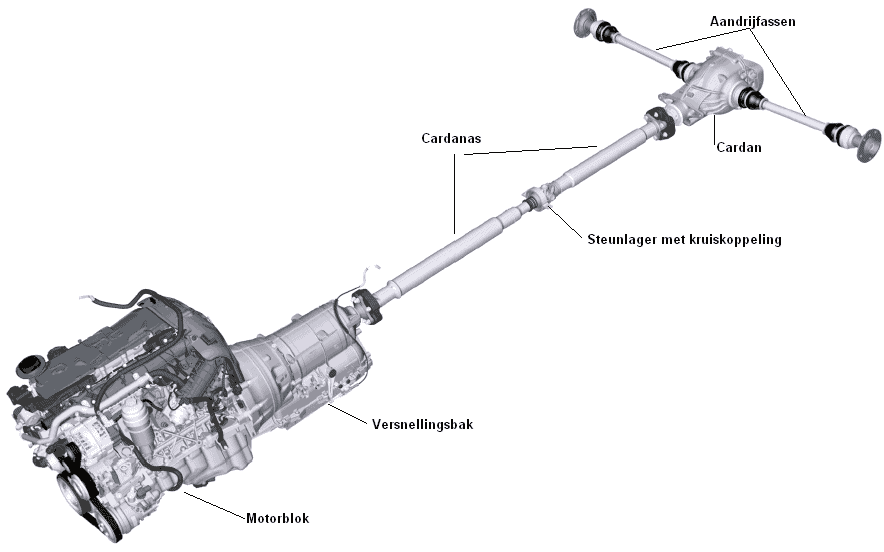

In front-wheel drive cars, the differential is located in the transmission. In rear-wheel drive cars, it is located at the rear axle, between the rear wheels. There is a driveshaft from the transmission leading back to the differential.

The image below is of a rear-wheel drive car. The shaft between the transmission and the differential (cardan) is called the driveshaft or intermediate shaft. This is described separately on the page driveshaft. The differential has two drive shafts attached to it that drive the rear wheels.

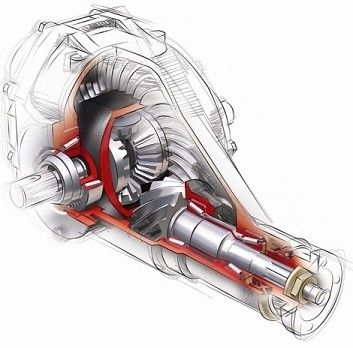

Crown- pinion gear:

The crown- pinion gear in the differential is mentioned separately because these parts must be very precisely adjusted after work. The pinion gear is attached to the driveshaft. The engine and transmission drive the driveshaft, and the pinion gear drives the crown gear. Adjusting the crown- pinion gear is a highly specialized task. Using factory specifications and measurement/adjustment equipment, the gears must be set together. A good adjustment results in the least noise and the longest lifespan.

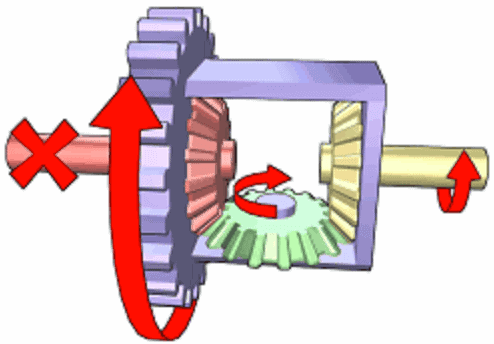

How the differential works:

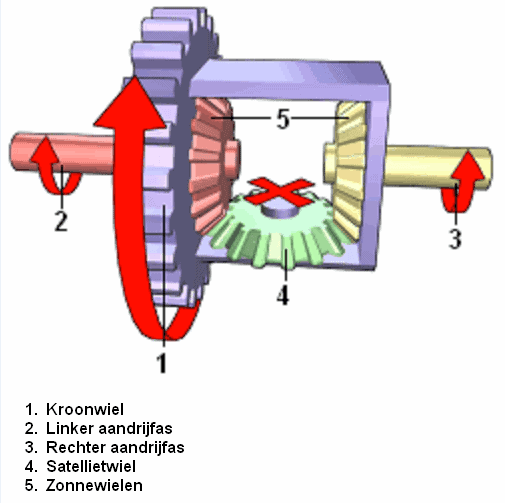

Crown gear 1 is driven by the pinion gear from the engine/transmission. When driving straight, drive shafts 2 and 3 will rotate at the same speed, and satellite gear 4 will not rotate on its axis.

In the situation shown in this image, the left drive shaft is stationary. This can occur if the left wheel is on asphalt and the right wheel is on an unpaved road. The wheel on the unpaved road will be slipping in this case.

The satellite gear now rotates on its axis, and all the drive force is applied to the right drive shaft. The left is now stationary. A similar situation also arises when driving through a corner, when tire pressure on one side is lower, when tire treads vary significantly, and when the road surface is not completely flat.

Drawbacks of a differential:

The differential’s ability to allow different wheel speeds can be a major drawback under certain conditions. When one of the driven wheels loses traction, the total drive is lost. If a car is on asphalt with one wheel and in mud with the other, the wheel in the mud will be driven 100%, and the wheel on the asphalt (with the most traction) will remain stationary. This occurs because the satellite gear spins rapidly, causing the wheel with the least resistance to be driven more.

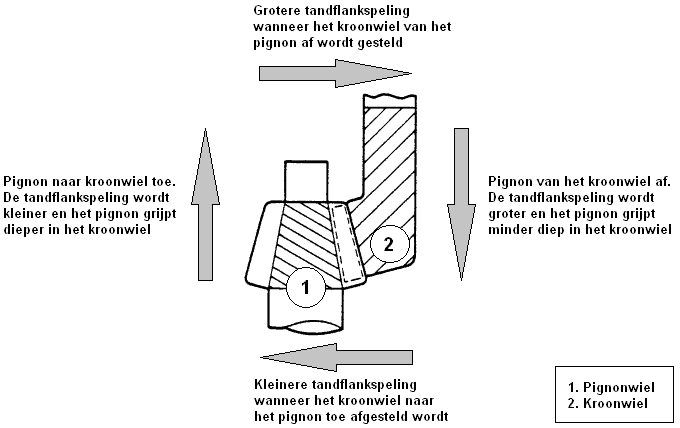

Adjusting the crown- pinion gear:

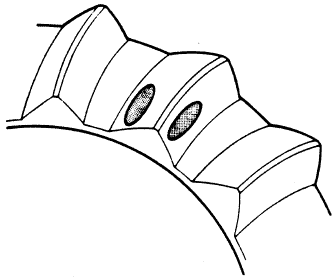

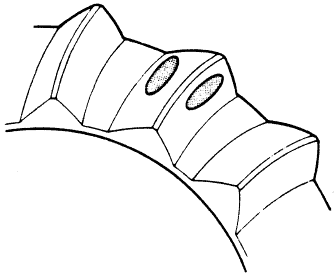

The height and the distance of the contact surfaces of the crown and pinion gear can be adjusted. The images show the consequences of incorrect adjustment.

By smearing the crown gear with special grease (which dissolves in oil) and turning it a quarter turn, the contact surface between the crown and pinion gear can be determined. By turning the pinion gear back and forth a few times, the contact surface becomes clear (see images). By adjusting and turning several times, it can be set to the ideal contact surface.

Consider that the load on the drive also causes the contact surface to shift. If the load increases, the contact surface moves more towards the outer edge of the crown gear (the top right image above). Under light load, the contact surface moves more inward. When adjusting, the contact surface should be centered. Always consult factory specifications for measurements.

Incorrect adjustment can cause (sometimes extreme) noise in the drive system, such as a whistling or howling sound. Wear will also increase. The differential can become defective after a few thousand miles due to careless (or no) adjustment. Of course, a loud noise will have preceded it.

LSD (Limited Slip Differential)

To prevent the above situation, it can be useful to (partially) disable the differential’s operation in some cases. This is called locking. When a differential is locked, the drive is equal on both axles. The satellite gear is immobilized, or both sun gears are coupled together. There are various developments with clutch packs, viscous couplings, and dog clutches.

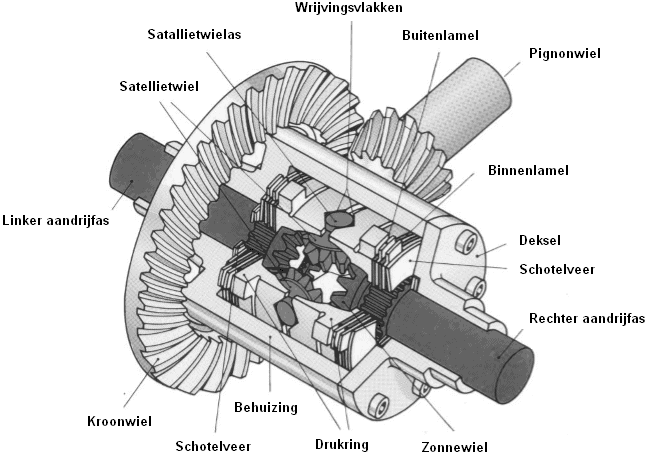

In the image below, an LSD (Limited Slip Differential) is shown. This is a differential with increased internal friction. Clutch packs are placed between the outer straight planes of the cone-shaped sun gears of the axle shafts and the differential housing.

The pressure rings in the LSD are partly connected to the differential housing and are also axially displaceable. The pressure rings are internally wedge-shaped due to the curved shape of the satellite gears. The inner clutch discs (dark-colored in the image above) engage with the internal teeth of the axle shafts. The external teeth of the outer clutch discs engage with the longitudinal grooves of the differential housing. As a result, the outer clutch discs cannot rotate.

When driving straight, the crown gear and the drive shaft rotate at the same speed, so there is no friction. If one of the wheels has insufficient traction and spins faster than the other wheel, a speed difference arises between the conical surfaces of the pressure ring. The pressure ring is pressed against the clutch discs, creating a load-dependent friction moment between the outer clutch discs (blocked by the differential housing) and the fast-spinning inner clutch discs connected to the drive shaft.

The more modern electronically controlled systems are developments based on the self-locking systems. The previously described pressure rings present in the self-locking systems are then replaced by hydraulically operated ring cylinders. Electronics control the clutch packs.

Torsen differential

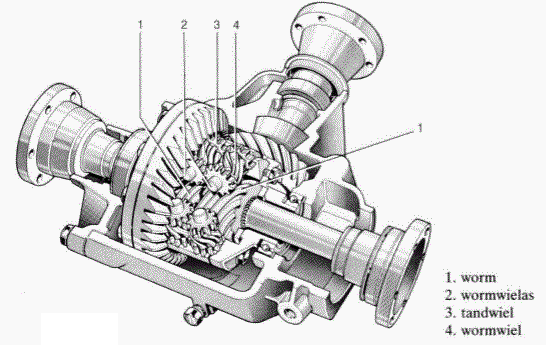

The Torsen differential (‘torsen’ is a contraction of ‘torque sensing’) is essentially a symmetrical differential. When both output shafts rotate at the same rotational frequency, the drive torques in these shafts are equal. If, for any reason, a differential effect occurs, the drive torque to the faster-rotating output shaft decreases, while it increases to the slower-rotating shaft. Here, too, an internal friction moment arises, which, on one hand, reduces the output torque and, on the other hand, increases it. The operation is based on the self-locking behavior of the worm gear drive achieved by selecting the appropriate lead angle for these gears.

The axle differential in the image below is bolted to the crown gear. Worm gear shafts are mounted in the differential housing. The worm gears, connected in pairs by cylindrical gears, can freely rotate on their axes.

Three sets of two worm gears each are installed. One worm gear from each set engages with the worm on the axle shaft to the right wheel; the other worm gear engages with the worm on the axle shaft to the left wheel.

When driving straight (forward or backward), with no differential effect, both shafts rotate at the same speed. The differential housing takes the worm gears along, which, in turn, drive the worms with the axle shafts. The worm gears, due to their leading direction, want to rotate in the same direction, which is not possible due to their coupling with cylindrical gears. Thus, the differential rotates as one unit, ensuring symmetrical torque distribution (50% – 50%).

If a differential effect occurs, for example, when driving through a corner, or if one wheel slips, one worm will rotate faster and the other slower than the differential housing. Now, a greater torque is transferred to the slower-rotating wheel than to the faster-rotating wheel. The faster-spinning worm drives its corresponding worm gear, and consequently the worm gear that drives the worm to the slower-spinning wheel. The torque to the slower-rotating wheel is further increased by the partially self-braking effect during the drive by the worm gear in the direction of the worm. By selecting the appropriate lead angle on the worm, the desired torque distribution, known as the lock value, can be achieved.

The Torsen differential has no effect on a potential ABS function, as the locking effect only occurs under load, therefore, when throttle is applied.

Especially in racing, with drifting, the differential is locked. When this is technically not possible in certain cars, the satellite gear is welded to the sun gears. In this cheap way, the differential is always locked. The downside is that it can hardly be driven on public roads, because the wheel with the least rotations in corners will slip. There is also an increased chance of damage to the drive shafts and CV joints.

Another method is to engage ESP (Electronic Stability Program). This system brakes the slipping wheel by briefly applying the brake caliper. By braking the slipping wheel, the differential’s action automatically transfers more power to the other wheel. This is sometimes also referred to as an electronic differential lock function.

Maintenance and faults in a differential:

Nowadays, differentials often contain “lifetime oil.” The manufacturer indicates that the oil does not need to be changed periodically. Some manufacturers do provide a replacement interval based on a set number of miles. This interval should not be exceeded. Even with differentials that have lifetime oil, it’s a good idea to occasionally change the oil. Every oil comes into contact with oxygen and undergoes an oxidation process, reducing its lubricating properties. Therefore, it is advisable to change the oil at a certain mileage (e.g., at 150,000km).

Faulty differentials, where the bearings are defective or the crown-pinion gear spacing is incorrect, cause a lot of noise in the drive system. Usually, differentials can be refurbished. During refurbishment, the tooth surfaces of the crown and pinion gear are measured, and the bearings are replaced. If the tooth surfaces are too worn, the parts will need replacement. Replacing the crown gear is often very costly.

Adjusting differential bearing preload:

The bearings in the differential must be mounted under a specific preload. This value is determined by the differential manufacturer. With either too low or too high a preload, the bearing can fail over time. Consider too high axial load that can cause the bearing to overheat. When overhauling the differential or replacing the bearings, the preload should always be checked and adjusted if necessary. Measurements are carried out to determine the thickness the shim should be (between the bearing and the seal holder).

Examples are provided below regarding the measurements to be carried out.

A depth gauge is used to measure the distance between the outside of the transmission housing and the bearing. The measured value in the picture is 12 mm.

This depth gauge can also measure the height of the shoulder of the seal holder. The measured value in the picture is 10.0mm.

During installation, the shoulder of the seal holder is mounted in the differential housing. By subtracting the two just-measured values, the distance between the differential bearing and the shoulder of the seal holder is determined: Depth – height = 12.0 mm – 10.00 mm = 2 mm.

When a 2 mm shim is placed between the differential bearing and the seal holder, the bearing would be installed stress-free.

Of course, that is not desirable; a thicker shim will need to be placed to mount the bearing under tension. The preload is prescribed by the manufacturer. This might be, for example, 0.25 mm.

The shim that should be placed in this case is the measured distance plus the preload, so; 2 mm + 0.25 mm = 2.25 mm. When the shim with a thickness of 2.25 mm is placed, the preload is correctly set. The suitable shim must be found in a box with different sizes of shims. With a caliper, the correct shim can be found.

The image below shows that the shim has a thickness of 2.25 mm. This is the correct shim. More information about measuring with a caliper can be found on the “Mechanical measuring tools” page.

The depth gauge measurements of the bearing and the height of the shoulder of the seal holder are carried out with the depth gauge shown above. These measurements can also be performed with a dial gauge. Instructions on measuring with a dial gauge are also provided on the “Mechanical measuring tools” page.

The measurement values in the images below do not match the measurements above. The photos are also quite blurry. They will soon be replaced with new images where the measurements are correctly depicted.

The values from the dial gauge and the depth gauge should align. It generally doesn’t matter what tool is used for the measurement, provided both measuring tools are available. In a practical exam, for example, it might be the case that only one type of measuring tool is provided. Thus, it’s important to be familiar with all measuring tools: the caliper, the micrometer, and the dial gauge.