Introduction:

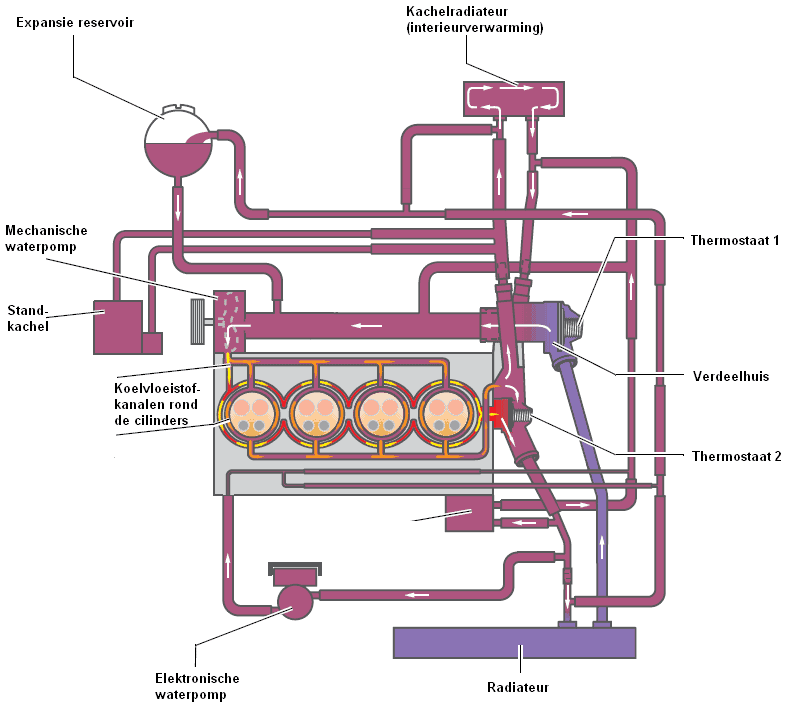

It is important to cool the engine because overheating can occur, lubrication can be compromised, and the risk of knocking (uncontrolled combustion) is highest. The thermal load on the engine also greatly affects its lifespan. Both the engine oil and coolant are responsible for internally cooling the engine. The cooling system of an engine contains several critical components listed below:

- Expansion tank; This stores a supply of coolant

- Heater core; for interior heating

- Thermostat; 2 pieces, distributed over 2 cooling circuits

- Radiator; Coolant is cooled here by passing air (ram air)

- Water pump; ensures the circulation of coolant. The water pump is usually driven by the timing or serpentine belt. Increasingly, the water pump is also driven electronically.

- Parking heater; preheats the coolant before the engine is started. This is often an option. Most cars are not equipped with a parking heater.

The cooling fan protects the cooling system from overheating.

Effects of Too Much or Too Little Cooling:

A lack of cooling can occur if the coolant does not circulate properly. This can be due to insufficient coolant (leakage), a blockage in the cooling system (e.g., the radiator), a defective water pump preventing proper circulation, or when the cooling fan / viscous fan does not activate. The following can occur as a result of insufficient cooling:

- Overheating;

- Seizure of engine components;

- Piston rings breaking;

- Thickening of engine oil. (Lighter components evaporate from the oil, making it thicker);

- Knocking.

Knocking can also occur due to gasoline with too low of an octane rating, an overly lean air/fuel mixture, ignition timing set too early, or carbon deposits in the combustion chambers. More information on this can be found on the knocking page.

- High fuel consumption (engine does not reach operating temperature).

- Internal contamination (at low temperatures, more combustion residues and dirt particles remain in the engine).

- Condensation of fuel particles (poorer combustion).

- Interior heater does not warm up.

Different Cooling Methods:

- Indirect cooling: Warm air is absorbed by coolant and then dissipated to the ram air in the radiator. This is why liquid cooling is called “indirect cooling.” Today, all passenger cars use indirect cooling.

- Direct cooling: The heat is eventually carried away by the ram air. Since heat in air cooling is dissipated to the outside air, it is referred to as direct cooling. Older cars were often air-cooled (e.g., the first VW Transporters and Beetles). By applying fins on the engine block, the parts were cooled by the ram air. Ram air cooling is a simple and cost-effective way of cooling. The ram air flows along the cylinder and directly absorbs the heat.

- Forced air cooling: A fan blows cool air past the cylinders and cylinder heads. Cylinders and cylinder heads are also equipped with cooling fins. By means of cladding around the fan and the parts to be cooled, the cooling air is distributed in such a way that uniform cooling is achieved.

The advantages of air cooling include that less maintenance is required. There can be no leaks as with liquid cooling, the liquid level does not need to be checked or replaced, etc. There is also a shorter warm-up period. The coolant does not need to be pre-heated at start-up, so an air-cooled engine reaches operating temperature faster. Wear during the warm-up period is therefore also reduced.

Pressure Test:

When the coolant level in the reservoir keeps dropping, there is likely a leak. Sometimes the leak is so minimal that it is not visible when looking at the engine block and surrounding components with a flashlight. The small amount of coolant that drops onto a warm part of the engine block, for example, can evaporate, leaving no trace of the leak.

Because the cooling system is pressure-free with the engine off (cold), no coolant will leak while standing still. In such cases, the car’s cooling system can be pressurized. Coolant can leak along seals that are dried out or cracked.

An example of the pressure test is shown in the image.

A pressure tester (often a hand pump with a gauge that shows pressure) is provided with a number of different adapter caps. Not every coolant reservoir connection or radiator cap is the same. After installing the correct pressure cap, the pressure tester can be connected to the cap with a quick coupling. By moving the piston rod of the pressure tester back and forth several times, overpressure is applied to the cooling system. The radiator hoses and coolant hoses on the engine will then become hard. It is sometimes necessary to keep the cooling system under pressure for at least an hour before a leak becomes visible. Drops can then form at the ends of hoses, thermostat housing gaskets, or other coolant cover plates.

The image shows leakage at the bottom radiator hose:

When a leak is discovered, it should be repaired with new parts. Sometimes a new gasket or O-ring costing a few euros is sufficient. Do not, under any circumstances, pour a sealant into the radiator. This so-called “radiator stop leak” can cause blockages in the cooling system. Not only is the opening where the leak resides sealed, but possibly also the coolant passages in the radiator or heater core.

Related page: