Introduction:

The body is the shell of the car, excluding loose components such as the chassis, drivetrain, and interior. Often we refer to a “self-supporting body” when the body and chassis are constructed as a single unit and are strong enough to have parts mounted directly onto them. It’s also possible for the body to be placed on the chassis, allowing for separation. On this page, various chassis and body construction methods are described.

Ladder Frame:

The ladder frame gets its name because the chassis indeed resembles a ladder. Between two thick longitudinal steel beams, several crossbeams are attached. All components of the suspension system are mounted to the longitudinal and crossbeams.

The ladder frame is mainly used in vehicles that need to carry significant weight, such as SUVs, pickups, off-road and commercial vehicles. Disadvantages include: high weight, taking up a lot of space, and not being flexible enough to absorb torsional forces during driving.

An example of a ladder frame is shown adjacent:

The body is attached to the ladder frame with screws. During repair work on the chassis or drivetrain, the ladder frame and body can be separated. This is shown in the image below:

The ladder frame enabled Ford in the early 20th century to mount different body shapes on one type of chassis on the assembly line. In the early days of the automobile, it was common to buy a chassis that defined the make of the vehicle, and then a coachbuilder would add the bodywork. This approach is still used similarly for trucks and buses.

Contemporary vehicles using a ladder frame include the BMW I3/I8, Chevrolet Silverado/Suburban/Tahoe, Ford Expedition, GMC Yukon, Jeep Wrangler, Mercedes-Benz G-Class, Toyota Hilux/Land Cruiser/Tundra.

Monocoque:

In a monocoque construction, there is no separate chassis and body. The supporting structure is formed by the shell, without internal reinforcements. An egg is a good example of this. The term “monocoque” is a combination of the Greek “mono” and the French “échelle coque,” meaning “hull shell.” The monocoque can be constructed from profiled steel sheets and carbon fiber. The latter offers the advantage of keeping the vehicle’s weight low. Since there is no separate chassis, this benefits cabin and engine bay space.

Vehicles that feature a monocoque body include a Formula 1 race car and the McLaren F1 (left and right in the image below).

Unibody:

In today’s vehicles, the unibody is often used. Unibody is derived from the phrase “unitized body.” The unibody consists of different box constructions, crossbars, and tubes. Not only the body constructions but also the bonded windows, roof structure, and floor panels contribute to the stiffness of the body. The body and chassis are considered a single unit. The drivetrain and chassis are mounted to this body using a subframe. We thus also refer to it as a “self-supporting body.”

The unibody is constructed from separate parts that are welded, glued, or screwed together. Because various parts are connected, not everything has to be made of one type of material, such as steel. An important advantage of this is that weight decreases. The use of lightweight materials like aluminum and carbon fiber doesn’t affect safety, as unibody vehicles usually have crumple zones and other structures specifically designed to absorb collision forces.

Tube Frame and Space Frame:

In the case of a tube frame, we also speak of a self-supporting body. A tube frame, also known as a space frame, is a complex three-dimensional structure of aluminum tubes that are connected. The tubes form the basis for the body and the chassis. The drivetrain, chassis, and sheet metal parts are attached to these aluminum tubes. An example of this is the Mercedes-Benz 300SL:

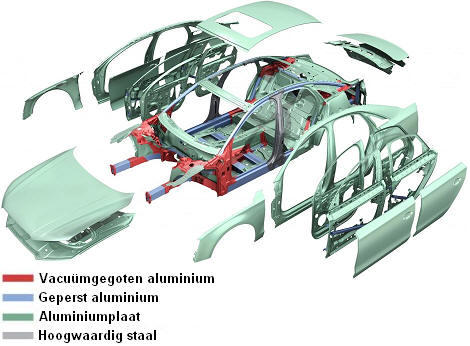

Audi also uses the term “space frame.” In the aluminum frame structure, all panels and plates contribute to body rigidity. Due to the very sturdy aluminum panels, the aluminum body is extremely strong and highly crash-resistant, while lowering vehicle weight. The construction of an Audi space frame is shown in the image below.

Backbone Chassis:

The backbone chassis is made from one or more steel profiles connecting the front and rear axles. The backbone chassis is strong relative to its weight. The disadvantage is that this type of chassis offers no protection in side collisions.

A car using the backbone chassis is the DeLorean DMC-12.

Self-supporting Body:

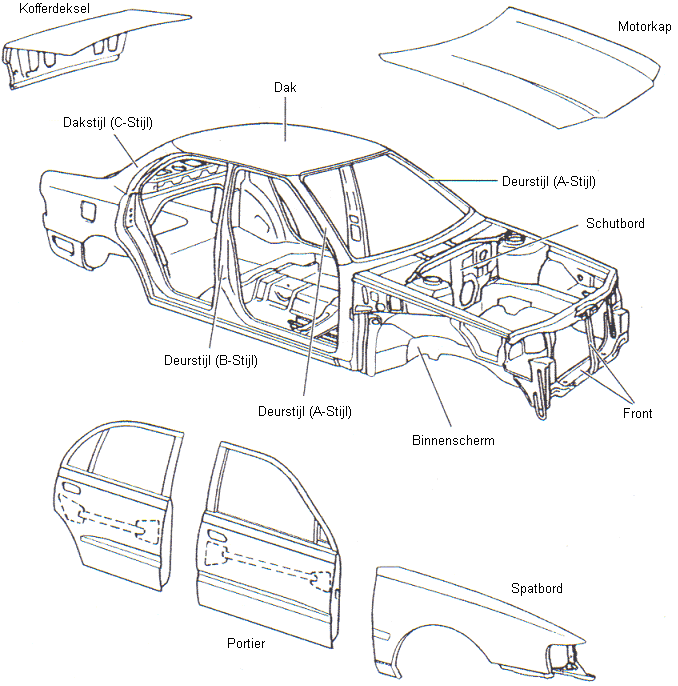

In the paragraphs above, the various body constructions are described. A unibody is an example of a self-supporting body. The floor pan, firewall, roof panel, door pillars, and even the bonded windows form the supporting elements of the self-supporting body.

Non-supporting parts include the doors, hood, trunk lid, fenders, and side windows. These parts are often bolted to the body and don’t contribute to body rigidity.

Window and Door Pillars:

Window and door pillars are often designated with a letter. The pillars from front to rear are called the A-pillar, B-pillar, etc. (see body image)

Related page: