Subject:

- Crumple zone and cage construction

- Body materials

- Crash Test

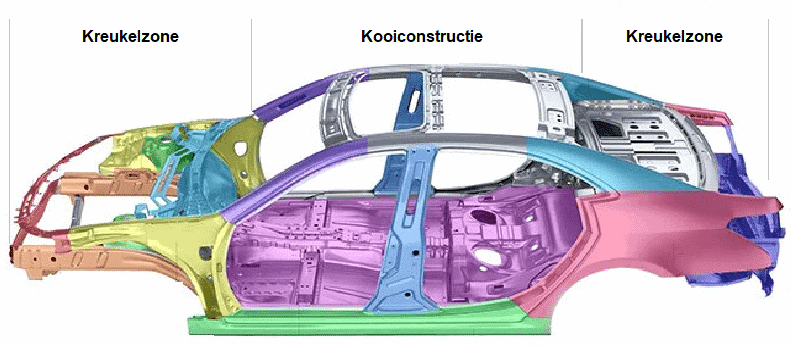

Crumple zone and cage construction:

Crumple zones are parts of a self-supporting body that has been deliberately weakened for forces in one direction, due to the use of more easily deformable materials than in other parts of the body. Crumple zones include, for example, the trunk or the front around the engine compartment. In the event of a collision, the area in the crumple zone will dent in a pre-calculated manner.

The force exerted on the entire bodywork will then be partly absorbed by the deformed materials. The delay will also be less, because the time that the crumple zone is dented, as it were, slows down the vehicle. The collision is thus absorbed as much as possible, which protects the occupants.

A so-called cage construction has been installed around the interior where the occupants are located. The materials in this part of the body are so strong that the cage construction will not or hardly deform in the event of a severe collision. The occupants will be protected as much as possible against entrapment in the event of collisions and rolling over.

The following image shows a crash test of a VW Touran, showing how the crumple zone absorbs the frontal impact and the material around the occupants is barely deformed.

In vehicles that did not yet have a cage construction, the bodywork around the interior will deform too easily. An example can be seen in the following image, where a VW Transporter T3 undergoes a crash test.

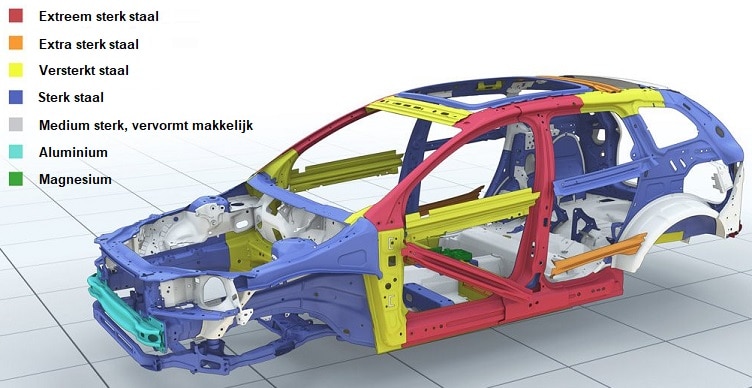

Body Materials:

In order to obtain a crumple zone and cage construction, a mix of materials has been used in the making of the car that can be easily or very difficult to deform. The image below shows the cohesion of different types of materials.

- The steel parts of the cage construction are marked in red. These parts must be as strong as possible to protect the occupants in the event of a collision;

- In addition, we also find extra strong steel in the rear doors;

- A mix of high-strength steel and medium-strength steel has been used around the engine compartment and trunk. These parts will easily deform in a collision giving us the crumple zone;

- Finally, we see an aluminum bumper beam, which is most easily deformed in a collision and possibly offers protection to a pedestrian or cyclist;

- In the interior we see a magnesium part. This can be a mounting bracket for the center console. This body part has nothing to suffer, so is as light as possible.

Crash test:

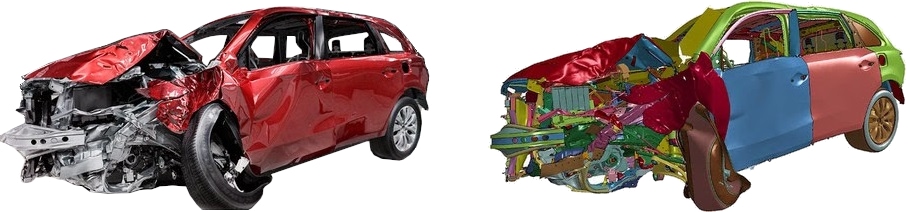

Manufacturers are obliged to have new vehicles tested for safety by means of a crash test. The vehicle is tested in all conceivable scenarios.

The data obtained from this indicates that the body and restraint systems are able to protect the vehicle occupants and pedestrians from injury during a collision. Important results are the deformations of the body, the steering column, the protection around the child seat, etc. So-called crash test dummies are placed in the car, which are used to make comparisons with the human body.

Crash tests are recorded by cameras to analyze the images. In addition to the human eye, the computer also analyzes the images. A crash simulation is then made with the computer: the deformation of the materials can be analyzed in even more detail.

Related pages: