Introduction:

Vehicles with electrified drivetrains (hybrid, full EV, fuel cell) have the capability to brake electrically. When releasing the accelerator pedal or applying light braking, the electric motor operates as a generator. The kinetic energy of the vehicle is converted into electrical energy for the HV battery. The range increases when braking gently, allowing the braking system to utilize significant regenerative braking. More about this can be read on the page: inverter.

As of 2023, electric braking is still combined with the conventional hydraulic brake circuit. In case of an electrical failure, or in older vehicles during an emergency stop, the hydraulic brake circuit is (partially) activated. This serves as a backup. The following paragraphs demonstrate how manufacturers combine electric and hydraulic braking to ensure good comfort and maintain safety should the electrical system fail.

Drive by Wire:

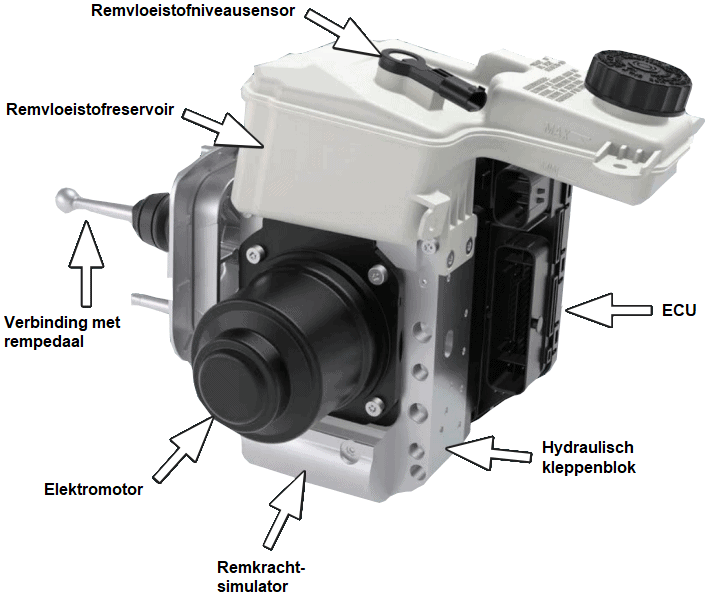

The “drive by wire” braking system aims to use electrical assistance for hydraulic braking. There is no direct hydraulic connection between the brake pedal and the brake pistons in the brake calipers. The brake pedal applies pressure to a so-called brake force simulator. The brake pressure is measured. An electric motor builds the desired pressure in the hydraulic brake circuit. The drive by wire braking system offers the following advantages compared to the conventional braking system:

- No vacuum brake booster is required since the electric motor provides the necessary fluid pressure;

- Fluid leakage can be recognized and isolated per brake. For this reason, no master cylinder is needed for two separate brake circuits;

- The driver does not notice a transition between electric and hydraulic braking when switching from regenerative braking with the electric motors to braking by pressing the brake pad against the disc;

- ABS system vibrations are no longer felt in the brake pedal;

- The (simulated) counterpressure in the brake pedal can be adjusted to settings (comfort / sport).

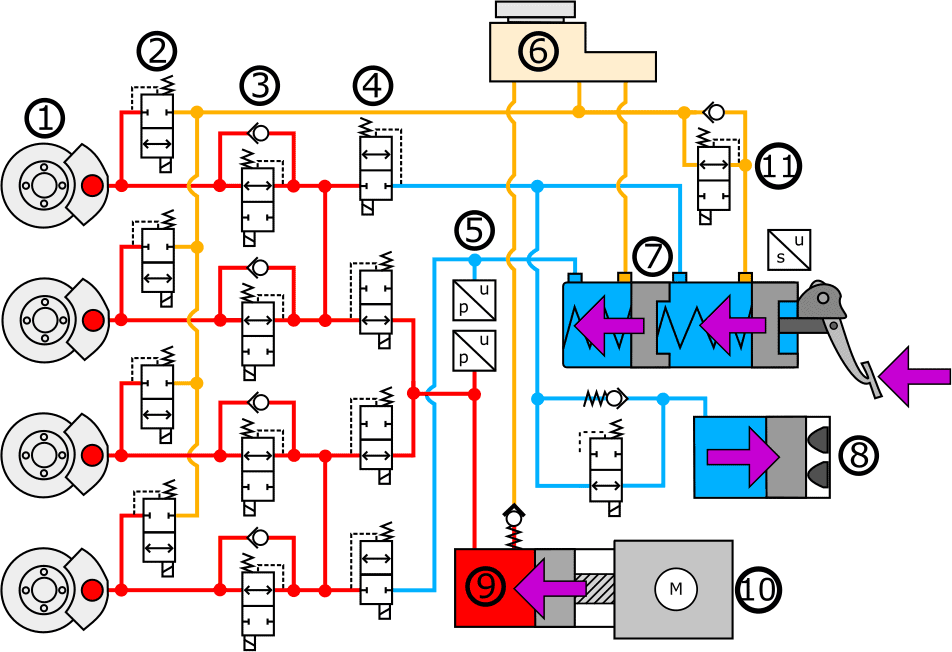

The schematic below shows the hydraulic system used by BMW (DSCi). The operation is as follows:

When the driver operates the brake pedal, force is applied to the master cylinder (7). This master cylinder has two outputs: to the brake pedal force simulator (8) and to a decoupling valve. The simulation pressure is transmitted to the brake pedal force simulator via the blue line. In this component, counterpressure is generated, which the driver recognizes as counterpressure in the brake cylinders. There is no physical connection from the master cylinder to the wheel brake cylinders. The simulation pressure is measured by a pressure sensor (5). The ECU controls, depending on the simulation pressure, the electric motor (10). This applies a working pressure in the brake pressure cylinder (9). A pressure sensor on the working pressure side feeds the built-up pressure back to the ECU. The red connections in the diagram show how the working pressure reaches the wheel brake cylinders (1) via the valves. The pressure retaining valves (3) are open at rest, allowing the brake pressure to be built up directly from the brake pressure cylinder. The pressure reducing valves (2) are closed at rest.

Legend:

- Brakes

- Pressure reducing valves

- Pressure retaining valves

- Decoupling valves

- Pressure sensors for brake pressure working circuit and simulator circuit

- Brake fluid reservoir

- Master cylinder

- Brake pedal force simulator

- Brake pressure cylinder

- Electric motor

- Diagnostic valve

- Yellow connections: supply and return of brake fluid reservoir;

- Blue connections: simulation pressure;

- Red connections: working pressure (brake pressure).

In the event of a leak near the brake pressure cylinder, or if there is an electrical failure that prevents the electric motor from building sufficient working pressure, the decoupling valves (4) are actuated to ensure safety. The connection between the master cylinder and the wheel brake cylinders is opened, and the connection to the brake pressure cylinder is closed. Because the brake booster is absent, one must apply more force to the brake pedal to brake.

Combination of Electric and Hydraulic Braking:

Fully electric and hybrid vehicles always have a combination of an electric and hydraulic braking system. The “brake by wire” braking system from the previous paragraph is not yet often applied. In that system, there is no direct connection between the brake pedal and the wheel brake cylinders. A powerful electric motor provides all the braking force, even in an emergency stop. In this case, a brake booster is not needed.

In most electric and hybrid vehicles, a combination of electric and hydraulic braking is achieved as follows: during gentle (controlled) braking, regenerative (electric) braking occurs because the electric motors function as dynamos. During hard braking and / or in case of malfunctions, the hydraulic system activates immediately. A brake booster is used here to enhance the brake pressure. Therefore, during braking, there is an interaction between the electric motor and the mechanical brakes. This system is sometimes also called “drive by wire,” although this term is more fitting for the system from the previous paragraph.

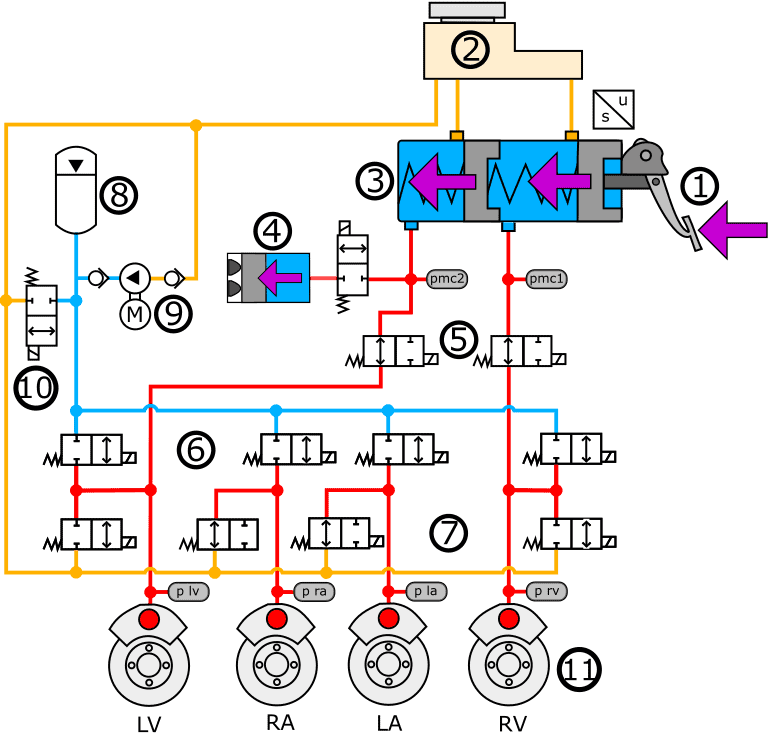

The schematic below is based on the Toyota Prius 3. With the brake pedal (1), brake pressure builds up in the master cylinder (3). During gentle braking, only the electric motors are used for braking. The brake pressure simulator (4) provides counterpressure while the brake pedal is pressed. The valve for the brake pressure simulator is opened in normal operating condition. During hard braking, the locking valves (5) open and the valve for the simulator closes. The front wheel brake calipers are provided with brake pressure. The opening and closing of the hydraulic valves (6) allow the brake pressure to also reach the rear wheels. The brake pressure sensors (from left to right: p lv to p rv) measure the pressure and transmit it to the ECU. Using a PWM signal, the hydraulic valves (5, 6, and 7) are regulated according to the desired brake pressure.

The system is designed so that in the event of a power failure, the brake pressure on the rear wheels is fully relieved, and the pressure on the front wheels is controlled by the driver with the brake pedal.

Legend:

- Brake pedal

- Brake fluid reservoir

- Tandem master cylinder

- Brake pressure simulator

- Locking valves

- Hydraulic valves (closed from left to right)

- Hydraulic valves, front closed, rear open

- Pressure accumulator

- Hydropump driven by electric motor

- Pressure relief valve

- Yellow connections: supply and return of brake fluid reservoir;

- Blue connections: brake pressure from hydropump;

- Red connections: brake pressure from master cylinder (when valves are open).

The hydraulic braking of the Toyota Prius 3 occurs via the front wheels. The rear wheels are not connected to the master cylinder. In modern vehicles, including the Kia Niro, this is the case: all four brake cylinders are actuated by the master cylinder through two circuits.

During the deceleration of vehicles with a similar braking system, there is a switch from electric to hydraulic braking under certain conditions. To ensure smooth brake deceleration and pedal feel, this braking system uses “brake blending.” This is described in the following paragraph.

Brake Blending:

When the accelerator pedal is released or during controlled braking, many electric vehicles rely solely on the electric motors to brake. The kinetic energy is converted into electrical energy, increasing the vehicle’s range. The hydraulic braking system is scarcely engaged. When significant braking deceleration is needed, the electric brake and hydraulic service brake work together. The collaboration of the two braking systems is known as “brake blending.” In earlier generations of hybrid and fully electric vehicles, this transition was not smooth, and the vehicle’s speed reduction changed as the hydraulic brake kicked in. With current technology, drivers no longer notice the transition between the two braking systems. Note: this is not the technique used in drive by wire.

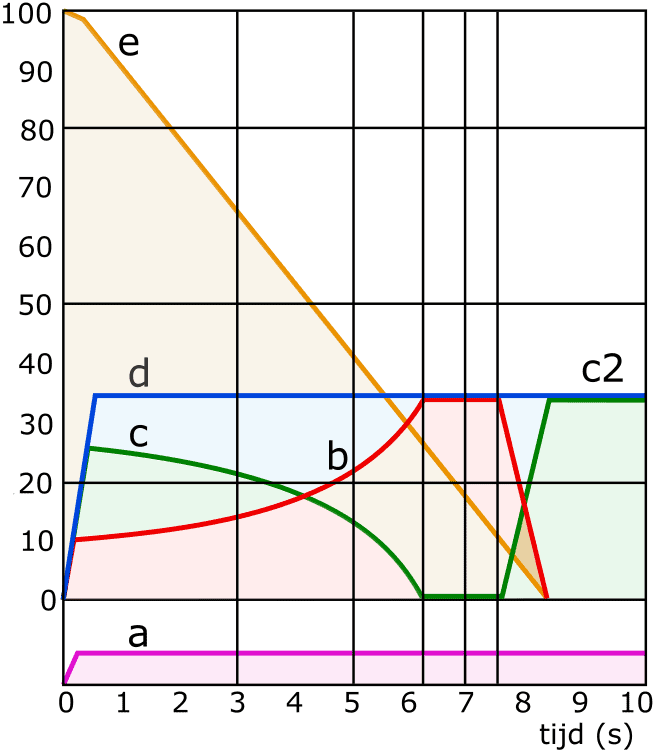

The graph shows the transition between the two braking systems where the braking deceleration remains constant. The driver’s pedal force (a) remains constant for 10 seconds. At the beginning of braking, the hydraulic service brake and regenerative braking on the electric motors work together. In the first six seconds, we see the deceleration from regenerative braking increasing. The electric motor functions as a generator supplying the HV battery with generated energy. The braking force of the hydraulic service brake progressively decreases until it is no longer active. After approximately 7.5 seconds, the vehicle approaches a standstill, and the electric braking force ceases. The hydraulic braking force increases again. After 8.5 seconds, the vehicle comes to a stop, and the driver briefly holds the brake pedal.

a: driver’s pedal force

b: deceleration from regenerative braking (with electric motor)

c: deceleration from hydraulic service brake

d: deceleration desired by the driver

e: reduction in speed

d = c + b

Related pages: