Introduction:

The brake system of a truck has three main functions: reducing speed, bringing to a stop, and holding stationary when parked. It differs from a passenger car because it uses pneumatic systems instead of hydraulics. The brakes are controlled through air from the pedal and the parking brake handle.

Heavy commercial vehicles and mobile machinery have air brakes, where the subsystems consist of:

- service brake

- emergency brake (auxiliary brake)

- parking brake

- continuous brake.

The first three subsystems are legally required.

The service brake allows you to reduce the speed of the vehicle or bring it to a stop. Operated with the foot, you should be able to control the braking force. Service brakes are friction brakes, which not only decelerate but also cause wear on brake linings, brake discs, and brake drums.a0Wheel brakes convert part of the kinetic energy into heat (frictional heat) and thus slow the vehicle down.

The emergency brake must ensure braking is still possible if the service brake fails. The parking brake locks a stationary vehicle to prevent it from rolling away and operates mechanically, as legally required.a0It is operated with the parking brake handle on the dashboard, which can also act as a parking brake. The parking brake is used to keep the parked truck in place and operates mechanically by venting the spring brake cylinders completely.a0

Commercial vehicles usually have a continuous brake system in addition to an air brake system. Continuous brake systems, such as the retarder (engine brake), hydrodynamic retarder (driveshaft brake), and electromagnetic retarder (also a driveshaft brake), are additional braking systems that reduce speed without bringing the vehicle to a stop, without thermally (over)loading the mechanical brake parts, during descending a hill.

Air vs. fluid:

For passenger cars and light commercial vehicles, it is common to have brake systems powered by brake fluid. However, in the case of heavy commercial vehicles, a different approach is required due to the need for more braking power and the resulting heat development during braking actions.

For trucks, brake components, especially drums, need to be larger to meet the required specifications. This includes not only a larger diameter but also a wider structure to provide room for more extensive brake linings. To prevent overheating of the brake linings, a substantial amount of lining material is needed to reduce thermal stress.

The larger surface area of the lining material is necessary to create sufficient friction between the drum and the lining. This leads to the need for a large wheel brake cylinder, which creates issues due to limited space for the brake lining. Enlarging the diameter of the master cylinder is also not an ideal solution, as this can affect the desired braking force.

These limitations result in an increase in fluid flow and a greater stroke of the piston in the master cylinder. This in turn leads to a larger pedal stroke, a reduced pedal feel, and a longer response time of the brake system. To overcome these challenges and meet legal requirements for braking deceleration in heavy commercial vehicles, a full air brake system is often chosen.

The advantages of a full air brake system include minimal effect of temperature rise on brake torque development, fast reaction time due to compressed air, and the possibility to easily influence brake force development by adjustments to lever ratios or surfaces of diaphragm cylinders.

Air supply, air consumption, parking brake, and components:

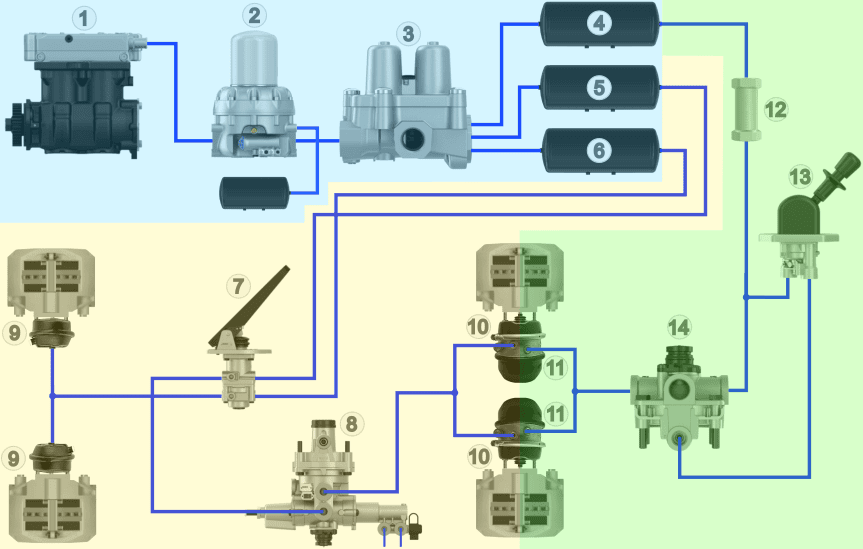

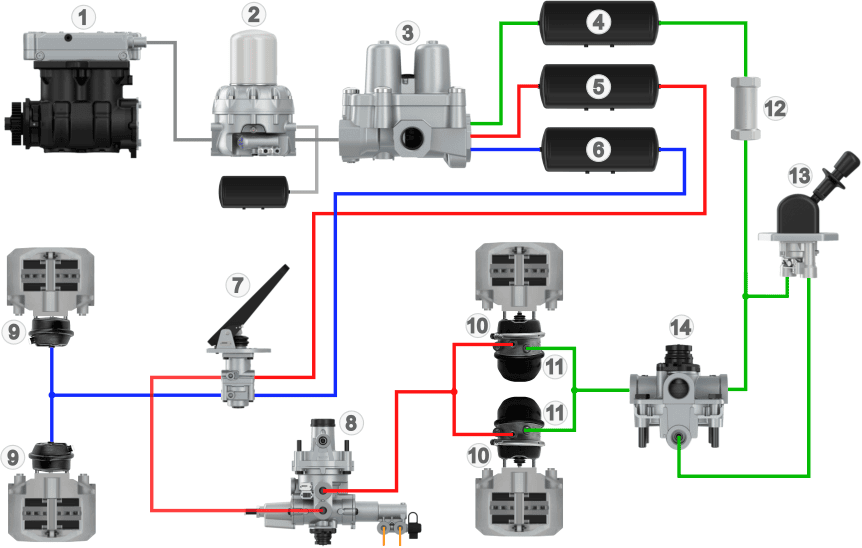

The service brake of a truck is composed of an air-supplying and an air-consuming section. In the image, the components belonging to these sections are color-coded in blue and yellow.

Air-supplying section:

The air-supplying section ensures that air is delivered at the correct pressure. In this section, the air is also cleaned and dried. The components that belong to the air-supplying section and are marked in blue in the image below are:

1. Air compressor: the air compressor contains two cylinders where air is drawn in and pressurized to the next component;

2. Air dryer: here, the moisture is removed from the compressed air. The filter has pellets that absorb the moisture. The wet tank is underneath the dryer;

3. Four-circuit protection valve: when a leak occurs in one of the three circuits, the air pressure in the other two circuits is maintained;

4 through 6. Air tanks: the air supply is stored in the air tanks.

Air-consuming section:

In the air-consuming section, the air from the air-supplying section is used. This section involves the operation, as well as regulations that adjust brake pressure based on load, and of course the brakes themselves. The air-consuming section is marked in yellow.

7. Foot brake valve: the position of the foot brake valve determines how much air is admitted to the brake cylinders. The driver operates the foot brake valve;

8. Load-dependent valve: the weight (load) on the rear axle is registered (mechanically or pneumatically). The ALR controls the relay valve;

9. Front diaphragm cylinders: the brake calipers of the front wheels are controlled with diaphragm cylinders.

10. Rear diaphragm cylinders: the calipers or drum brakes of the rear wheels are controlled with the diaphragm cylinder, which is located in a combined spring brake cylinder.a0

Legend:

1. Air compressor

2. Dryer with wet tank

3. Four-circuit protection valve

4. Air tank circuit 3

5. Air tank circuit 1

6. Air tank circuit 2

7. Foot brake valve

8. Load-dependent valve (ALR)

9.a0Diaphragm cylinders (front)

10. Diaphragm cylinders (rear)

11. Spring brake cylinders (rear)

12. Check valve

13. Parking brake valve

14. Relay valve

- Blue: air-supplying

- Yellow: air-consuming

- Green: parking brake / emergency brake

Parking brake and emergency brake:

In addition to the air-supplying and air-consuming section, we also see the parking and emergency brake section marked in green. When the truck is parked, the driver can operate the parking brake. In case of emergency, the emergency brake can be activated to bring the vehicle to a stop. The following components are in the parking and emergency brake section:

11: Spring brake cylinder: at rest, without air pressure, the spring in this combined spring brake cylinder keeps the vehicle braked;

12: Check valve: this ensures the brakes do not drag if a leak occurs in circuit 1, 2, or 4;

13. Parking brake valve: this handle is located within reach on the dashboard. With this handle, the parking brake can be activated or deactivated;

14. Relay valve: the amount of air from the parking brake valve determines the passage from tank 4 to the spring brake cylinders 11.

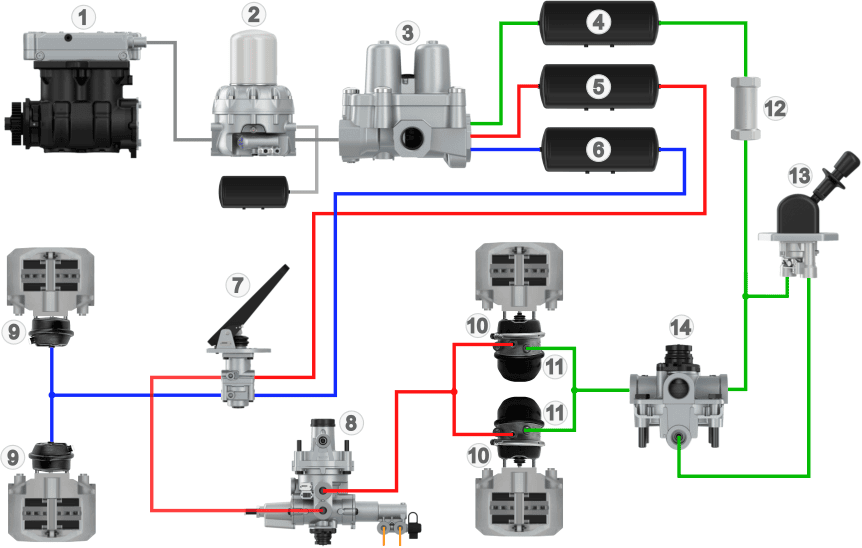

Circuits in the air brake system:

In the air brake system of a truck, there are three circuits:

- circuit 1: rear brakes

- circuit 2: front brakes

- circuit 3: parking brake / emergency brake

- circuit 4: accessories such as engine brake, air horn, and cab suspension

- circuit 5: air suspension. Previously, the air suspension was connected to circuit 4. In new vehicles, this circuit is tapped before the valve due to a higher pressure and fast response time.

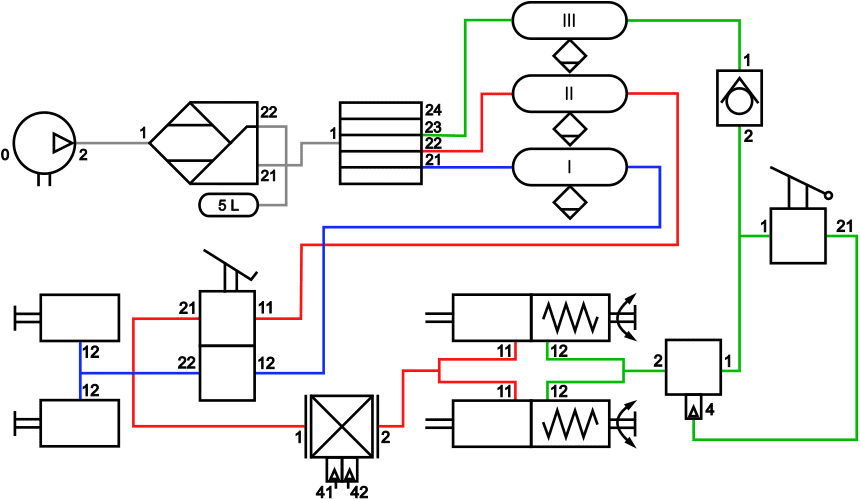

The image below shows the three circuits of the brake system, which are separated in the four-circuit protection valve. The service brake consists of circuit 1 (blue for the front axle) and circuit 2 (red for the rear axle). Both circuits have their own air tanks (5 and 6 in the image), with the air pressure at approximately 10 bar. The parking brake / emergency brake (green) has its own air tank (4). The air pressure is approximately 8 bar.

Legend:

Circuit 1: Red

Circuit 2: Blue

Circuit 3: Green

This overview does not yet include a trailer brake valve, as we are focusing on the basics of the air brake system of the motor vehicle on this page. On the page: trailer brake the above diagram is expanded with the trailer brake valve and the associated components and additional air pipes.

Codes for air brakes:

The air brake system of a truck consists of multiple circuits, such as the service brake, parking brake, accessories, and air suspension. When coupling a trailer, one circuit of the brake system is extended. When maintaining, repairing, or diagnosing, it is important to identify the correct components and lines. To keep it organized, all inlets and outlets of the valves are coded. These codes indicate where the line comes from and where it goes. In line diagrams and functional diagrams, the codes can be found.

0: Air compressor suction connection

1: Air supply (inlet) to a component

2: Air discharge (outlet) from a component to another component

3: Ventilation / blow-off opening to the outside air

4: Control connection for a relay function of a valve

5: Free (often used from an air spring in trailer EBS)

6: Free

7: Frost protection

8: Lubricant (81: supply, 82: discharge)

9: Coolant (91: supply, 92: discharge)

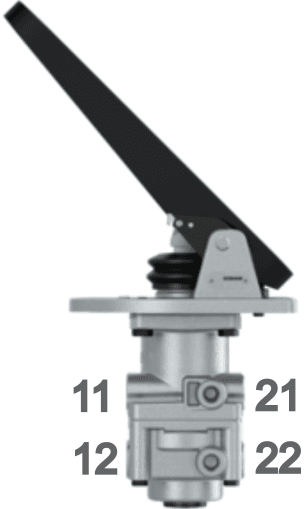

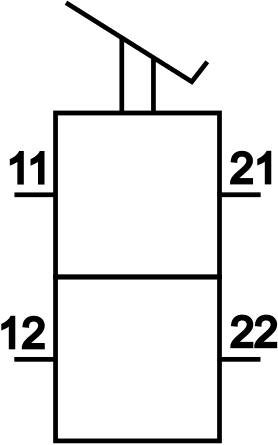

A component can have multiple inlets and outlets. The coding then consists of two digits, with the first indicating what type of connection it is and the second the sequence number. The foot brake valve, for example, has two inlets and two outlets for circuit 1 (front axle) and 2 (rear axle).

- inlet circuit 1: 11

- inlet circuit 2: 12

- outlet circuit 1: 21

- outlet circuit 2: 22

The following images show an illustration of a foot brake valve (drawing: Wabco) and the symbol of a foot brake valve, both with the codes.

In the images below, we see the diagram of the air brake system with all components (above) and the diagram with the same setup in which the separated circuits with all symbols and codes of this brake system are shown (below).

Legend:

1. Air compressor

2. Dryer with wet tank

3. Four-circuit protection valve

4. Air tank circuit 3

5. Air tank circuit 1

6. Air tank circuit 2

7. Foot brake valve

8. Load-dependent valve (ALR)

9. Diaphragm cylinders (front)

10. Diaphragm cylinders (rear)

11. Spring brake cylinders (rear)

12. Check valve

13. Parking brake valve

14. Relay valve

Legend:

Circuit 1 (rear brakes): Red

Circuit 2 (front brakes): Blue

Circuit 3 (emergency brake / parking brake): Green

Related page: