Introduction:

The rear windshield wiper motor is mounted in the car’s tailgate. There is a hole in the window or paneling of the tailgate through which the shaft of the wiper motor protrudes. The wiper arm is mounted on this shaft with the wiper blade. Naturally, the shaft cannot make full rotations because not only the rear window but also the rest of the tailgate or bumper would be wiped by the wiper blade. Therefore, the motor contains a mechanism that ensures the shaft can make a movement of up to 180 degrees.

The rear windshield wiper motor always operates at one speed. The wiper switch can turn it on and off, and there is usually an interval; after switching on, the motor will be activated every few seconds.

The wiper always returns to the starting position after being switched off. If it did not, the wiper arm would stop halfway on the window when the switch is set to the “off” position. Instead of the power supply to the motor being cut off, it remains connected until the zero position is reached.

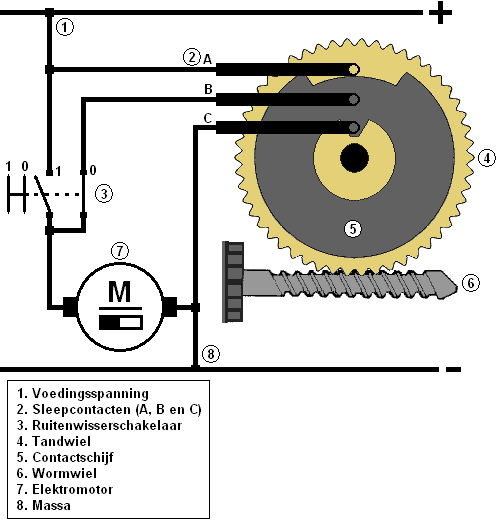

Components of the windshield wiper motor:

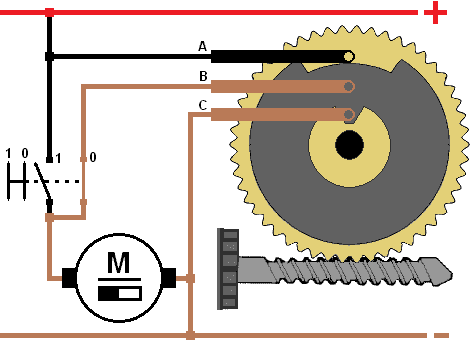

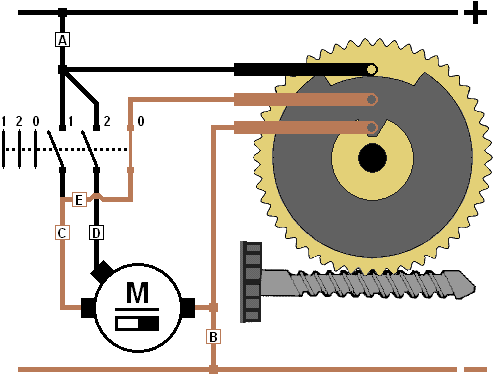

To return the wiper arm to the starting position, the motor contains an internal contact plate with slip contacts. The following images illustrate how the windshield wiper motor operates.

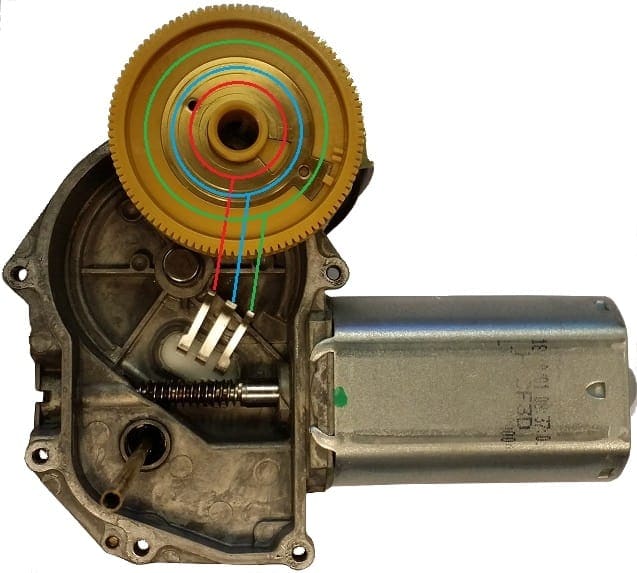

The rear plate of the windshield wiper motor is disassembled. The red arrow indicates where the round cam of the mechanism moves back and forth in the rear plate. The mechanism ensures that the rotating motion of the yellow plastic gear is converted into a back-and-forth motion of the output shaft. The output shaft is shown upright in the image. The wiper arm is mounted on this shaft.

The image on the right shows the disassembled windshield wiper motor with the worm gear and the plastic gear. Here, the mechanism is disassembled.

The text below corresponds to the image below. The yellow plastic gear is now turned over. The notches and recesses of the conductive contact disc are clearly visible here. The positions where the slip contacts touch the contact disc are indicated in red, blue, and green.

To visualize the positions where the slip contacts make contact with the conductive contact plate, they are marked in red, blue, and green. Below is an explanation of the function of each slip contact:

Red: This always carries 12 volts with the ignition on.

Blue: This slip contact is responsible for the park position.

Green: This is the ground. This is how the motor is connected in the park position.

The three slip contacts “slide” over the gold-colored contact plate as the motor turns. A notch and a recess are made in the contact plate. Therefore, the slip contacts never all touch the contact disc at the same time. The middle contact (marked in blue) is responsible for movement to the park position. The contact plate is conductive; if the motor is not in the starting position, the inner (red) and middle (blue) slip contacts have a connection with each other. Voltage is transferred from the red contact to the blue contact through the contact plate. Thus, the motor can continue rotating until the red slip contact reaches the notch. At that time, it can no longer transfer power to the blue contact. The motor’s operation is then halted.

At the same time, the outer slip contact connects via the recess (marked in green) to the blue slip contact through the contact plate. The green slip contact is connected to the vehicle’s ground. This contact functions as a sort of brake. This brings the wiper motor to a stop. The ground is transferred from green to blue. The motor is short-circuited to ground on both sides and thus remains in the park position.

Connecting the windshield wiper motor:

To connect the wiring of the windshield wiper motor, first study the operation of components such as the contact plate and slip contacts. Only after understanding which points carry voltage can you proceed with measuring and connecting the wiring.

The wiring harness in the tailgate for the rear windshield wiper motor often consists of three or four wires. A constant voltage, switched voltage, and a ground need to be measured on these wires. On the remaining wire, where nothing is measured, a supply voltage (for a ground-switched motor) or a positive voltage (for a positive-switched motor) will be present when the motor is in the rest position. This wire can only be measured when all wires are connected and the wiper motor is in the starting position. In all other cases, nothing is measured.

There are positive-switched and ground-switched windshield wiper motors. This means the switch is located on the positive or the ground side of the electric motor. It is very important to know this before measuring. The following chapters describe each step in detail. Pay close attention to the differences between the positive-switched and ground-switched variants!

Plus-connected windshield wiper motor:

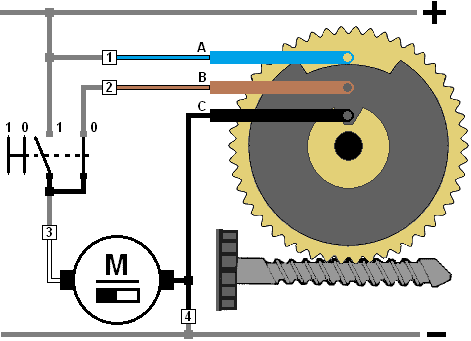

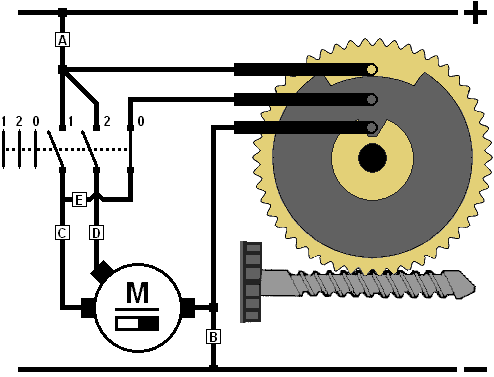

Based on the diagrams, it is also possible to determine how to connect this motor, for example, during the practical examination. Below is a diagram with a legend of the plus-connected rear windshield wiper motor. The wiper motor is stationary, and the switch “0” is closed.

The electric motor (7) receives direct battery voltage only at a constant speed. In that case, switch 1 is closed, and switch 0 is open. The electric motor (7) drives the worm gear (6), which in turn rotates the gear (4). The gray conductive contact disc is attached to the plastic gear and will therefore also rotate. When the wiper switch is set to the off position, the contact disc (5) and slip contacts A, B, and C (2) ensure that the motor stops in the correct position. This is clarified below.

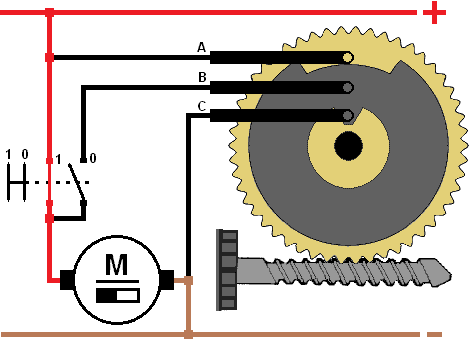

Windshield wiper motor activated:

In this situation, the windshield wiper motor is activated. Power is supplied via the red positive wire. Switch 1 is closed, which provides the motor with a constant power supply. The other side of the motor is grounded, so the motor will rotate at a constant speed. The worm gear is driven by the wiper motor and will therefore also rotate. In this case, it has no effect on the motor’s power supply.

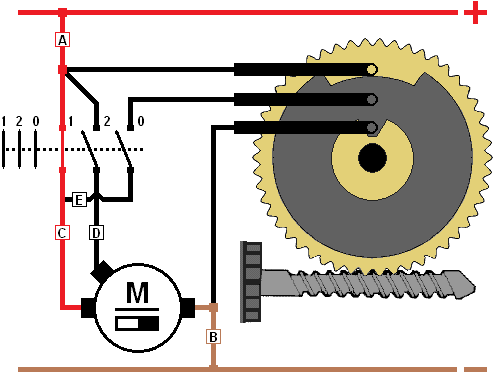

Switch in off position, wiper still moving:

In the image below, the wiper switch is set to the “off” position. This opens switch 1 and closes switch 0 (of the park position). At this moment, current flows from slip contact A, through the gray contact plate to slip contact B. The current then flows from slip contact B, through switch 0, to the wiper motor. Because the gear is driven by the worm gear through the wiper motor, the contact plate will also rotate. Until the notches of the contact plate return to the top position, the motor will keep turning.

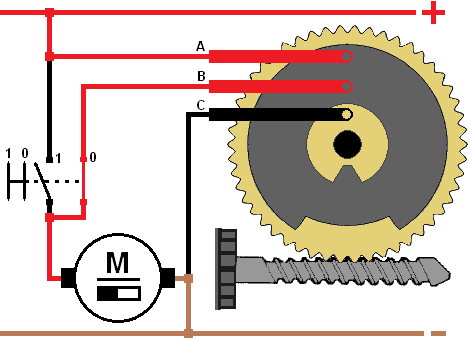

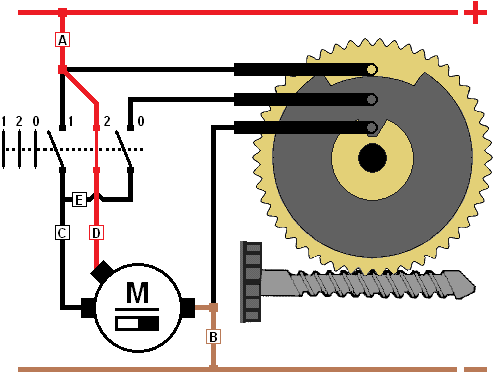

Switch in off position; wiper stops:

The gear continues to rotate until the notches of the contact plate reach the top position, breaking the contact between slip contacts A and B. Slip contact A is insulated by the (yellow) plastic gear, preventing current from flowing to slip contact B. No current will flow to the windshield wiper motor either. When the contact plate rotates far enough, slip contact C also makes contact with the small conductive part of the contact plate. At this moment, slip contacts B and C are connected, and since C is always connected to ground, B now also makes contact with ground via the contact plate. The windshield wiper motor is connected to ground on both sides at this point, stopping it immediately. This effectively works as a brake. The windshield wiper motor always stops in the same place this way.

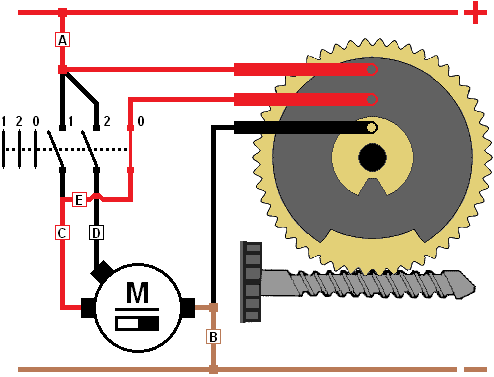

Animation:

In this animation, the different positions of the switch and contact plate are clearly visible. Here is a brief summary of the explanation given above.

- Disabled: the switch is in the park position, and the electric motor is short-circuited with both positive and ground.

- Enabled, constant speed: the switch is in position 1, and the contact plate makes two clockwise rotations. In this position, the contact plate is not used.

- Switch in position 0, moving to park position: the contact disc ensures power to the motor until the notches reach the slip contacts.

- A-B (positive interrupted), B-C make contact. This has a braking effect on the motor, which stops almost immediately.

When, for instance, during a practical exam, wiring needs to be connected, the correct positions of the switch must be sought. Using the windshield wiper motor’s diagram, it is possible to determine which pin in the connector is responsible for power, ground, or the park position. By measuring on which wire in the car’s wiring harness 12 volts is present, this can be connected in advance. Using a resistance measurement, it is possible to determine which connection is the ground. The ohmmeter will show a resistance value of less than 1 ohm at this connection. It is essential that the negative lead is held to a good grounding point on the chassis. Then, by moving the switch through several positions, it is possible to find which wire corresponds to which switch position. Subsequently, it is possible to determine, using the diagram, which wires need to be connected together.

From theory to manufacturer’s diagram:

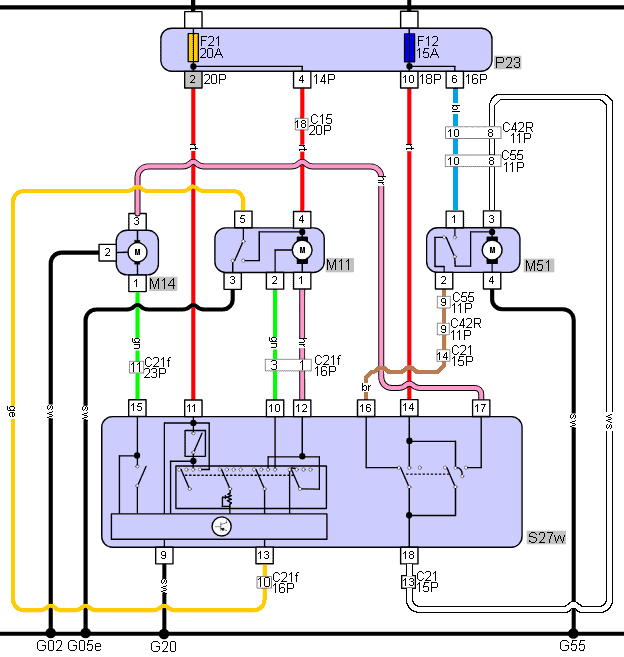

The theory of the rear windshield wiper motor was covered in the previous paragraph. In the diagrams, it can be clearly established how the contact plate in the disassembled windshield wiper motor ensures that the motor receives power to return to the starting position. This section explains how this diagram can be translated into a manufacturer’s schematic.

The following electrical diagram is based on the rear windshield wiper motor of a Hyundai Getz. The wire colors (blue, brown, white, and black) correspond to the colors of the car.

Numbers 1 to 4 in the diagram on the right and below show the pins of the connector that connects the windshield wiper motor to the car’s wiring harness. The numbers and wire colors in both diagrams match. The following diagram is sourced from HGS-data.com. The rear windshield wiper motor here is designated with the component code: M51.

In both diagrams, it can be seen that the blue wire (pin 1 in the connector) is the constant positive wire from the fuse. The brown wire (pin 2) is responsible for reversing to the park position. In the following diagram, the contact plate is depicted as a mechanical switch. The switched positive wire from the switch is connected to the white wire (pin 3). The black wire is the ground wire (pin 4) and is connected to a ground point on the chassis (G55).

In the rest position, the electric motor is short-circuited with ground; the white and brown wires make contact with each other via the contact disc.

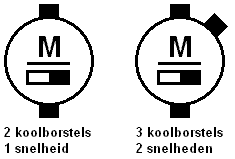

Windshield wiper motor with two speeds:

Thus far, only the single-speed windshield wiper motor has been discussed. This is suitable for the rear window. The windshield wiper motor for the front window can often operate at two different speeds, namely the normal speed used for both interval (first position of the switch) and continuous wiping (second position), and the high speed (third position). There is a speed difference in the electric motor between the second and third positions of the wiper switch. This is achieved by using multiple brushes. In the single-speed wiper motor, there are two brushes, while in the two-speed wiper motor, there are three. The image on the right shows the symbols of a wiper motor with one and with two speeds.

At the higher speed, fewer armature windings are engaged. The counter-electromotive force generated by the rotating armature is now smaller. Because less back EMF is generated, the armature, and thus the entire electric motor, has a higher speed.

The diagram of the two-speed wiper motor closely resembles the diagram discussed above. Here, the windshield wiper motor is again positively switched.

Three switch positions are visible:

– Position 1: low speed, continuous rotation.

– Position 2: high speed, continuous rotation.

– Position 0: off, return to start position (park position).

The first position is engaged in the diagram on the right. This is the low speed.

Position 2 is engaged here. Now the motor receives positive voltage through a different brush. There is now a lower back electromotive force in the electric motor, resulting in a higher speed compared to the connection of the other brush.

Position 0 is selected in this diagram. The motor is switched off but first returns to the start position. The contact plate connects slip contacts A and B with each other, so the wiper motor still has a power supply. When the contact plate rotates 180 degrees further, the contact between slip contacts A and B is broken, cutting off the power supply.a0

The operation with the contact plate and the slip contacts is the same as with the single-speed wiper motor.

In this situation, the contact plate has rotated again, allowing slip contacts B and C to make contact with each other. The motor is now grounded on both sides. The wiper motor remains in this position until it is reactivated.

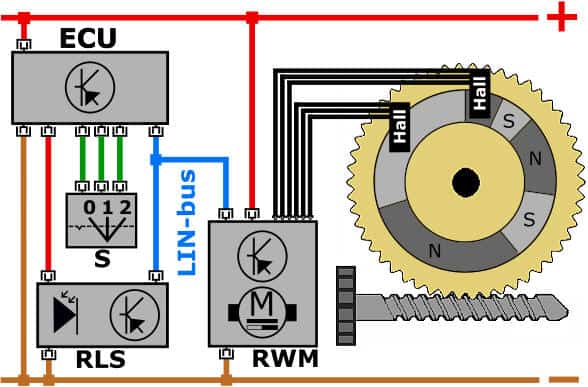

LIN-bus controlled windshield wiper motor:

The previously mentioned systems rely on voltage controls originating from the windshield wiper switch. In modern cars, control via LIN-bus is increasingly used. The control unit manages the windshield wiper motor. Multiple inputs, from both the switch (S) and the rain/light sensor (RLS), send a signal to the ECU to activate, change the wiping speed, or deactivate the wiper motor (RWM).

The diagram shows the components responsible for controlling the windshield wiper motor.

The switch (S) is connected to the ECU with the three green wires. These wires communicate the switch position.

The switch therefore has no direct connection to the RWM, as was the case with conventional control. The RLS receives its power from the ECU (12 volts), its ground through a grounding point, and transmits its signal via the LIN-bus wire to other connected components. The RWM is controlled by a signal on the LIN-bus. The control unit within the RWM (identified by the transistor symbol) is responsible for the actual control of the electric motor.

In conventional windshield wiper motors, the position of the conductive contact plate determined the movement to the park position. In a LIN-bus controlled windshield wiper motor, this contact plate is replaced by a position disc and Hall sensors. The position of the position disc depends on the position of the plastic gear and therefore the position of the wiper arm. The position disc is divided into a number of north and south poles (N for North and S for South). Because each north and south pole on the position disc has a different size, the control unit in the RWM, along with the Hall sensors, can determine the precise position of the gear. When the RLS or switch ends the activation of the windshield wiper motor, the control unit in the RWM controls the electric motor until the position disc reaches the “park position.”

Advantages of this control include:

- PWM control allows for different speeds.

- The rotation direction of the electric motor can be reversed; rotating clockwise moves the wiper arms up, and rotating counterclockwise moves them down. This allows for a smaller installation space for the wiper mechanism.

- The park position can vary; by slightly moving the wiper blades up occasionally, the rubber of the wiper blade bends in the opposite direction. The wiper blade does not always rest in the same position on the windshield, positively affecting the blade’s lifespan.

The LIN-bus signal can be measured with an oscilloscope. The displayed waveform shows the communication between the ECU (the master) and the rain/light sensor and the windshield wiper motor (the slaves).

On the page LIN-bus, the composition of a LIN-bus message is described. Additionally, communication of the windshield wiper system is extensively explained, and it is clarified how malfunctions in the LIN-bus signal can be recognized.

Related pages: