Wheel Bearing:

A wheel bearing allows the wheel to rotate around its axis. The wheel bearing ensures smooth transmission of movement between the drive shaft and the steering knuckle. Properly functioning wheel bearings ensure that the wheels can turn with minimal resistance.

Wheel bearings are usually designed as angular contact bearings, deep groove ball bearings, or tapered roller bearings. The different types of bearings are described on the page Bearings.

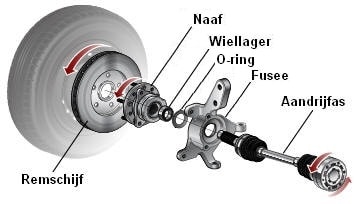

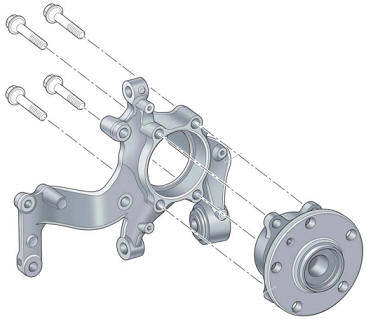

The wheel bearing in the image below is pressed into the steering knuckle. The hub is pressed into the inner ring of the wheel bearing. Thus, the wheel bearing connects the rotating hub with the steering knuckle. The drive shaft provides the power transmission from the transmission to the wheel. The outer splines of the constant velocity joint are inserted into the inner splines of the hub. This transmits the driving forces from the drive shaft to the hub, where the brake disc and wheel are mounted.

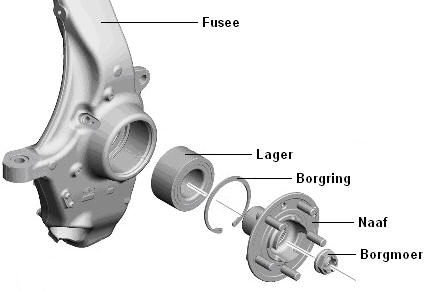

To replace the bearing, the hub must be pressed out from the inside of the bearing. A bearing puller or slide hammer can also be used to remove the hub. The bearing will always be damaged in the process, so it must always be replaced after disassembly. Once the hub is removed from the bearing, the bearing must be pressed out from the steering knuckle. The image below shows an overview of the bearing and hub assembly. The lock nut is screwed onto the axle and ensures the bearing is mounted under preload.

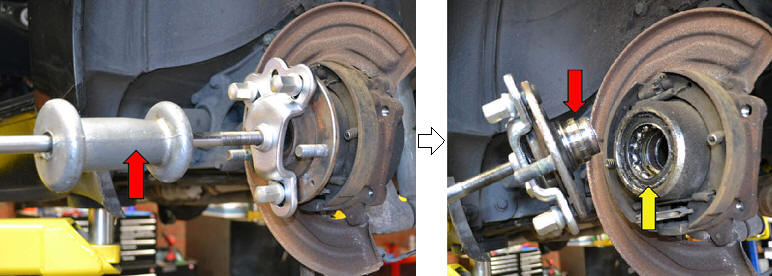

In the image below, the hub is pulled out of the bearing with a slide hammer.

The remaining bearing can be pressed out from the hub using pressing tools. In most cases, the inner ring of the old bearing is still on the hub. If the old hub is to be reinstalled, this ring must be ground or knocked off. There is a risk that the hub will be damaged if not handled expertly.

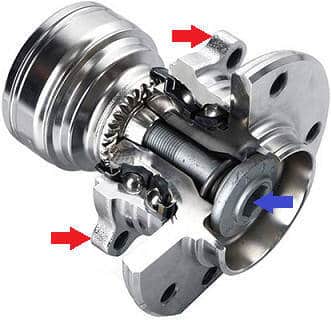

Not all wheel bearings need to or can be pressed. There are also so-called cassettes, which are bolted as a unit to the steering knuckle. Examples of these can be seen in the images below.

To replace this type of wheel bearing on a driven axle, the drive shaft must be removed (secured with the bolt indicated by the blue arrow in the lower left image), and the bolts of the steering knuckle must be removed (indicated with two red arrows). These are often four bolts.

Wheel Bearing with ABS Magnet Ring:

Nowadays, the magnet ring of the ABS is often integrated into the wheel bearing. In this case, there is no longer a toothed ring normally mounted against the hub. A magneto-resistive sensor (MRE sensor) or Hall sensor registers the wheel speed as the magnets in the magnet ring move past the sensor. This ABS sensor sends a square-wave signal to the ABS control unit based on the speed of the magnet ring.

Compared to the ABS system with an inductive sensor and toothed ring, this system offers the advantage that speed is measured from 0 km/h versus 5 km/h with the inductive sensor. Thus, this system works even at lower vehicle speeds.a0

Replacing such a wheel bearing is more complex than a bearing without an integrated magnet ring. The magnet ring must obviously not be damaged during installation, but the mounting direction must also be considered carefully. The bearing can often be installed in two ways. Sometimes the mistake is made to mount the bearing the other way around, placing the magnet ring on the brake disc side. In that case, the bearing will need to be removed again, resulting in its failure and requiring a new bearing.

To check whether the magnet ring is on the correct side, special magnetic cards can be held against the wheel bearing (see image).

Defects and Malfunctions:

Wheel bearings can become defective for various reasons:

- Age

- Hitting curbs

- Insufficient grease due to incorrect installation or a leaking seal

- Sporty driving behavior

- Driving through industrial areas where iron ore is present, allowing iron filings to enter the bearing

A defective wheel bearing is recognizable by a humming noise that increases at higher vehicle speeds. The humming noise should not be confused with cupped tires. The noise of a defective wheel bearing often changes when taking turns. For example, if a wheel bearing on the left side of the vehicle is defective, the noise will be louder when the left wheels are more loaded. This happens when steering to the right; more lateral forces and weights are applied to the left wheels. When steering left, the right wheels will be more loaded, reducing the noise. If the noise doesn’t change when steering left or right, the likelihood of tire cupping is greater.

The video clearly shows the sound of a defective wheel bearing.

Another defect that can occur in wheel bearings is play. The play can be felt by jacking up the wheel, gripping the tire at the sidewalls, and moving it back and forth (see image).