Introduction:

Variable valve lift height is a technique that allows the lift height of the valve to be adjustable when the camshaft opens the valve. This controls how far the valve opens, benefiting both fuel consumption and engine power. Variable valve lift height is only applied to the intake camshaft. Various techniques are utilized by different manufacturers, some of which are described on this page.

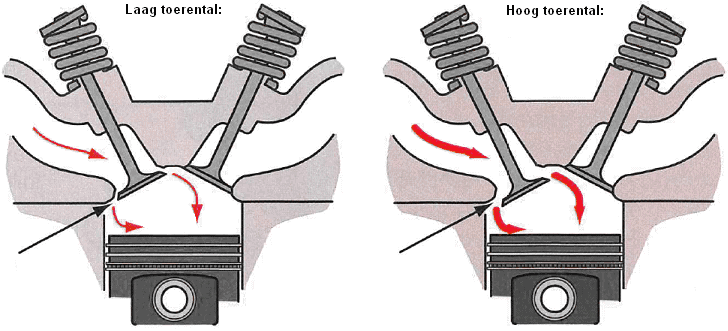

The image shows how the intake valve is opened further at a higher engine speed.

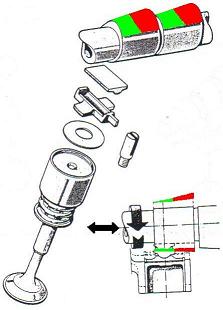

Axial Shifting of the Camshaft:

In this system, the camshaft is shifted longitudinally. The green section on the camshaft indicates the cam height at low RPMs and low power. In this section, the intake valve will not open far. The red section on the camshaft indicates the cam height at high RPMs and/or high power, in which case the valve will open further. This system is used by Honda and is known as “V-tec.”

The camshaft shifts because a solenoid feeds oil into an oil chamber.

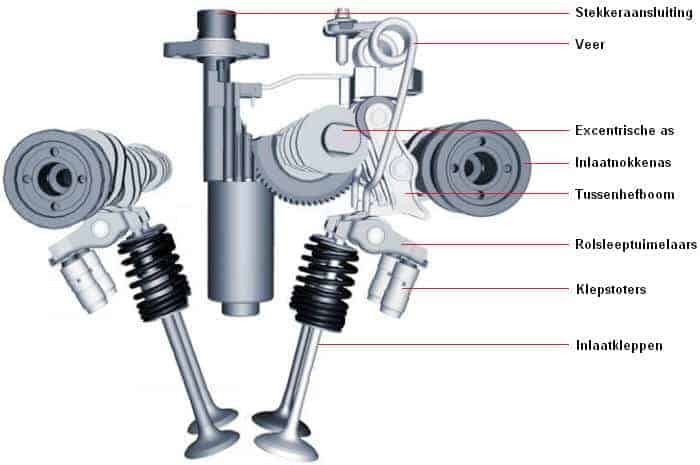

Valvetronic:

BMW’s Valvetronic system allows the height at which the valve is opened to adapt to operating conditions. With the engine idling, the valves will only open a few millimeters; due to the small air gap, the air entering the cylinders will have a high velocity. This high air velocity creates better swirling, leading to better distribution of the fuel mist, resulting in optimal combustion.

At higher speeds or loads, the valves will open further.

The Valvetronic system fully takes over the function of the throttle, which otherwise opens more as the RPM and load increase. Therefore, the throttle is redundant and not present in engines using Valvetronic.

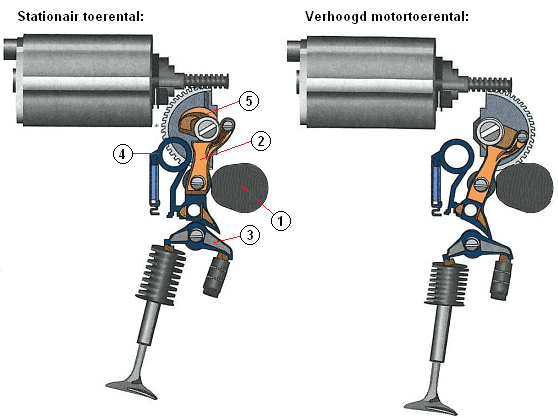

During engine idle, the camshaft (1) will push against the intermediate lever (2). The intermediate lever will pivot at the top around the eccentric shaft, causing the bottom to move left. Since the bottom pushes the roller rocker arm (3) downward, the intake valve will open. As the camshaft rotates further and the cam is at the top, the spring (4) will push the intermediate lever back to its original position, closing the intake valve.

At increased RPMs or higher loads, the electric motor rotates the worm gear, and therefore, the gearwheel of the eccentric shaft (5). With the eccentric shaft rotated, the thicker part will now tilt the intermediate lever. The intermediate lever will stand at an angle, causing the bottom of it to push the roller rocker arm for the intake valve further down. The intake valve will now open further.

By continuously adjusting the lever based on engine RPM and load, the valves will open further or less far accordingly.

MultiAir:

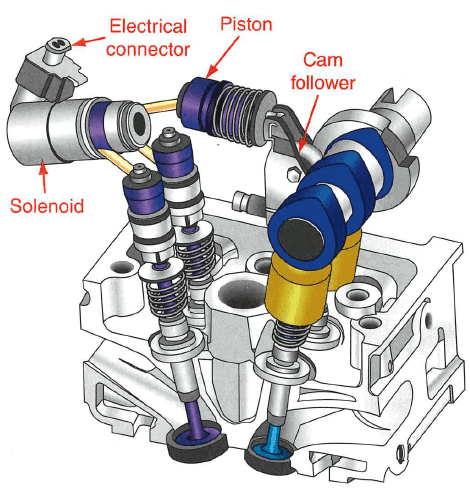

MultiAir is a fully electronically controlled system to manage the opening and closing of the intake valves independently via electronic-hydraulic actuation. MultiAir controls both the valve lift height and timing of the intake valves. It is applied to both gasoline and diesel engines. An adjustable camshaft is no longer necessary with MultiAir.

In MultiAir, there is a hydraulic connection between the camshaft and the intake valve. The camshaft drives the piston of the MultiAir high-pressure cylinder via a roller rocker arm. The piston in this high-pressure cylinder presses the oil towards the electronically controlled valve; also known as the solenoid or solenoid valve. The oil volume passed to the oil chamber above the intake valves is varied by the electronically controlled valve. Less oil volume means the intake valve opens less. This electronically controlled valve is precisely actuated by the engine control unit (ECU). Thus, both timing and lift height can be precisely adjusted to the engine’s air demand.

When engine power is needed, such as when driving at higher speeds and loads, the intake valve will open fully.

During engine start and idle, the intake valve will open later. There will be a large vacuum in the combustion chamber, which increases airspeed when the intake valve opens. This results in better mixture formation and combustion.

At medium RPMs and partial engine load, the intake valve will close earlier. This prevents interference in the intake manifold and reduces gas exchange losses, ultimately resulting in higher engine torque.

At medium RPMs and partial engine load, “multilift” occurs. With multilift, the exhaust valves open several times per power stroke, improving combustion quality.

MultiAir also allows the intake valves to open briefly at the end of the exhaust stroke, adding a small portion of exhaust gases to the intake air, creating an internal EGR.

Related pages: