Topics:

Introduction:

This page discusses the vacuum pump of the brake booster. More information about the brake booster can be found on the brake booster page. The same story about the vacuum pump is also discussed there.

The necessary vacuum for a vacuum brake booster is often obtained from the engine vacuum in a gasoline engine. A hose runs from the brake booster to the intake manifold. Because there is a vacuum in the intake manifold, vacuum is also drawn from the booster. If the engine is turned off and the brake pedal is pumped several times, the pedal will feel hard. This is because all the vacuum has disappeared from the brake booster. When the engine is restarted, the pedal will drop again and be further depressible. Therefore, always keep in mind that when a vehicle is towed; in the car where the engine is not running, 3 to 4 times more force will need to be applied to the pedal. Also, the power steering will not work. It is therefore sensible to drive carefully.

It may happen that the pedal feels hard immediately after turning off the engine; it seems as if the vacuum disappears immediately. This can be due to a cracked vacuum hose between the brake booster and the engine, or a defective check valve in the hose. This is usually a round piece of plastic between 2 parts of the hose.

If the hose in question is cracked, it should be replaced as soon as possible. If it further cracks or breaks, the entire brake boosting will fail.

In newer gasoline engine technologies (with high pressure injection / lean mixture), turbo engines and in no diesel engine is it possible to obtain sufficient vacuum from the intake manifold, as they work with an air surplus (a maximum amount of air is constantly supplied), requiring a separate vacuum pump.0There are 2 different vacuum pumps, namely the vane pump and the diaphragm pump. The vane pump is also known as the tandem pump or vacuum pump.

Vane Pump:

The vane pump is the most commonly used pump for obtaining vacuum in the brake booster. Often, this pump is mounted directly on the rear of the camshaft on the cylinder head, but it can also be driven by the Multi/V-belt or alternator.

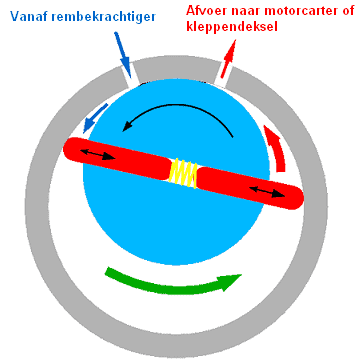

The operation is as follows; when a (red in the image) vane rotates past the pump inlet, the space behind the vane increases. The yellow spring presses the vane against the wall, causing this space to grow. In the area with the blue arrows, vacuum is now generated. As the pump continues to rotate, the air (indicated by the red arrow) is discharged to the engine crankcase or valve cover.

Diaphragm Pump:

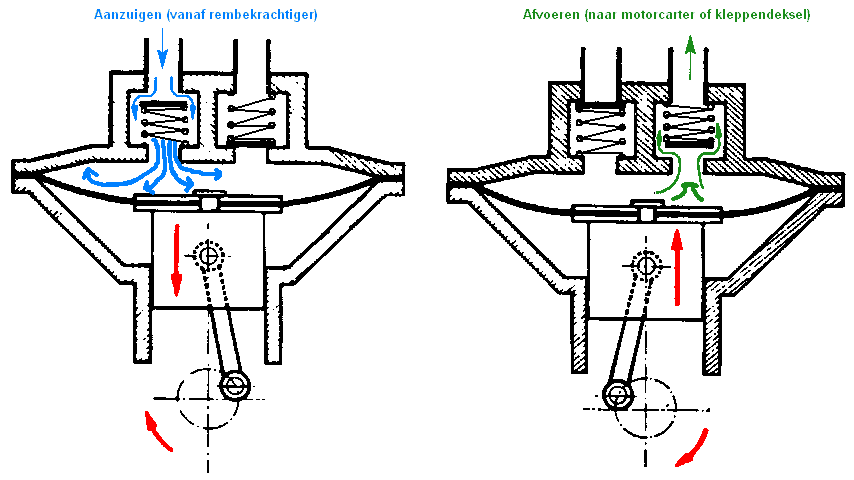

The diaphragm pump is placed between the vacuum brake booster and the intake manifold, engine crankcase, or valve cover. The movement of this pump is similar to the movement of the piston, connecting rod, and crankshaft in the car engine. During the downward stroke (left), the space above the diaphragm increases, and the valve is pulled downward. Air now flows from the brake booster (blue) into the pump. When the piston moves back up, the right valve opens (right image). The air is now discharged to the engine crankcase or valve cover.

Related page: