Introduction:

Modern diesel engines are subject to increasing demands. Consumers seek more comfort and power, while governments and other agencies enforce stricter environmental standards. Car manufacturers are compelled to innovate cleaner and more fuel-efficient engines that also deliver more power. Examples include the common-rail and unit injector fuel injection systems. The unit injector system was developed by Volkswagen.

Volkswagen employed the unit injector technology for the:

- 1.2 TDI,

- 1.4 TDI,

- 1.9 SDI,

- 1.9 TDI 105, 110, 115, 130, and 150 hp,

- 2.0 TDI,

- 2.0 SDI,

- 2.5 R5 TDI,

- 5.0 V10 TDI.

Due to emission requirements, new cars no longer use unit injectors, replacing them with common-rail systems.

Operation:

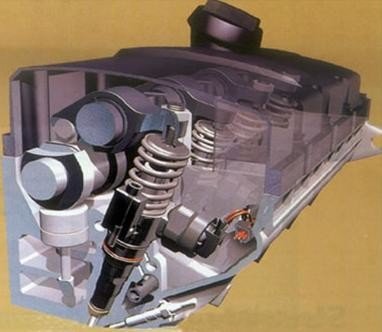

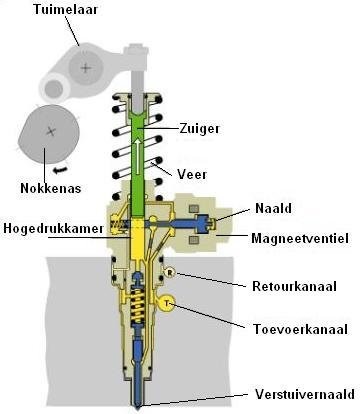

The unit injector system is a direct fuel injection system. An electronic fuel pump delivers diesel with a pressure of approximately 7.5 bar from the tank to the fuel supply of the unit injectors. This pressure fills the pump element. The pump element of the unit injector is operated by the camshaft via a rocker arm. Pressure builds in the pump element when the rocker arm pushes the injector needle down. The quantity of injected fuel is controlled by the solenoid valve; the longer the control unit activates the solenoid valve, the more fuel isa0injected.

With unit injectors, multiple injections can occur in successiona0as follows:

- Pilot injection: The solenoid valve starts the process. Pilot injection softens the start of combustion, reducing diesel knock. The liftoff height of the injector needle is 1/3 of the maximum height during pilot injection. The opening pressure of the injectors is then 180 bar.

- Main injection: The opening pressure for main injection can reach up to about 2000 bar. This pressure is achieved when the engine delivers maximum power. Main injection ends when the solenoid valve ceases to be activated.

The rocker arms operating the pistons in the unit injectors are driven by the camshaft. During the pump stroke, high fuel pressure builds in the high-pressure chamber. The pressure above and below the injector needle is equal, keeping the needle closed.

When the solenoid valve is activated, pressure below the injector needle disappears, and the pressure above it forces the needle down.

The unused fuel supplied to the injector is returned to the tank via the return channel.

Replacing and adjusting unit injectors:

After removal or replacement of a unit injector, it needs adjustment based on two measurements.

- The first measurement ensures the unit injector is mounted straight in the cylinder head, using the caliper.

- The second measurement adjusts the maximum stroke of the piston in the unit injector.

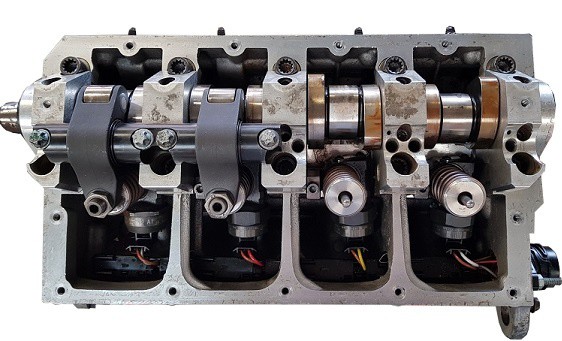

1. Remove the rocker shaft.

To replace a unit injector, one of the two rocker shafts must be removed. In this case, the rocker shaft for the unit injectors of cylinders 3 and 4 is removed.

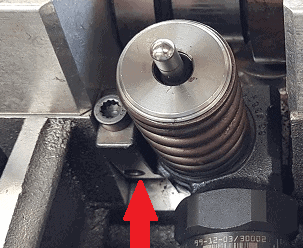

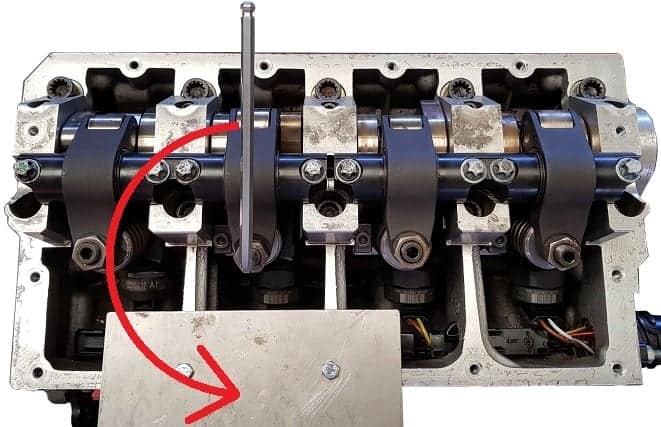

2. Remove the tensioning block.

To remove the tensioning block, the bolt (indicated with a red arrow) must be loosened. The tensioning block is hooked into the injector and must be slid out.

3. Remove and install the unit injector.

Use the puller to extract the unit injector from the cylinder head. Hook the protruding part of the puller into the section where the tensioning block hooks into the unit injector.

Install new O-rings on the injector before reinstallation. Carefully press the injector back into the cylinder head and attach the tensioning block. Do not tighten the bolt yet, as the injector still needs adjustment.

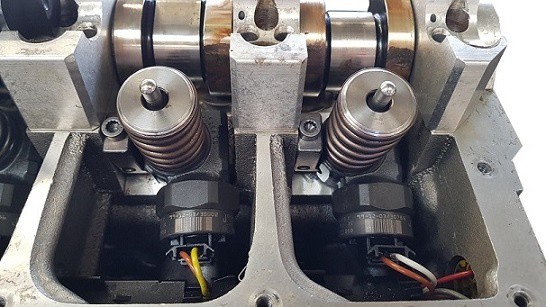

In the image, the injector of cylinder 3 is replaced (left) and noticeably misaligned. Adjustment is performed in step 4.

4. Adjust the unit injector’s position.

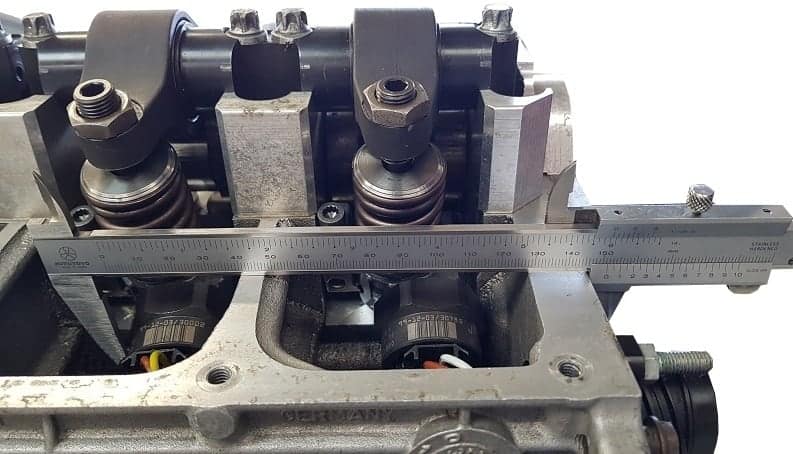

Using the caliper, measure the distance between the bulge of the injector and the outer side of the cylinder head. This is shown in the image.

If the measured value does not match the manufacturer’s specification, the injector must be rotated. This alters the bulge’s distance to the cylinder head’s outside.

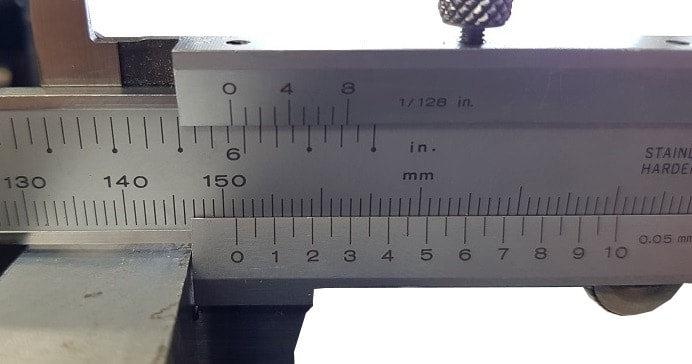

The prescribed distance is 151.3 mm b1 0.9 mm, meaning ideally, it should be 151.3 mm, with a permissible deviation of 0.9 mm. The following image shows the measurement, with an enlargement displaying the scale reading.

An enlarged view of the scale is shown for step 4’s measurement, indicating a size of 151.3 mm, the manufacturer’s specification. The bolt for the tensioning block cana0bea0tightened.

Keep the right jaw of the caliper on the cylinder head for measurements on other unit injectors. Each injector will have different adjustment values. A 400 mm caliper range is needed to measure the injector of cylinder 1 (distribution side).

5. Attach the dial gauge.

Mount the dial gauge on the injector being replaced. Allow the dial gauge to rest on the rocker arm’s side that lowers when operating the unit injector.

The dial gauge must always contact the rocker arm; thus, it should be pressed onto the rocker arm with preload. The needle will contact the rocker arm during its movements. Ensure the preload is at least 3 mm.

6. Rotate the crankshaft until the rocker arm reaches its lowest point.

This measurement aims to identify the lowest point of the rocker arm. The following measurements are conducted on the unit injector of cylinder 2.

As the crankshaft rotates, the rocker arm drops, and the dial gauge reading decreases with the needle moving counterclockwise.

The needle halts at the lowest point. As the crankshaft turns further, the needle climbs again. The point where the needle stops indicates the rocker arm’s lowest position, initiating the adjustment procedure.

7. Adjust the unit injector (1).

Loosen the lock nut and then turn the adjustment screw fully up until the rocker arm contacts the top ring of the unit injector.

8. Adjust the unit injector (2).

Turn the adjustment screw as far as possible into the rocker arm. This compresses the unit injector’s spring. Turning may be difficult. Stop turning when significant resistance is felt, as this indicates the piston in the unit injector is contacting the bottom of the high-pressure chamber.

9. Turn the adjustment screw back 180 degrees.

Now that the adjustment screw is fully tightened, it should be turned back half a turn. This prevents the piston in the unit injector from contacting the bottom of the high-pressure chamber each time the camshaft operates the unit injector.

If multiple unit injectors are replaced, repeat this measurement for each. Be aware that adjustment instructions may vary by engine code or year!

The instructions and images provided above are for reference only and do not constitute a guarantee.

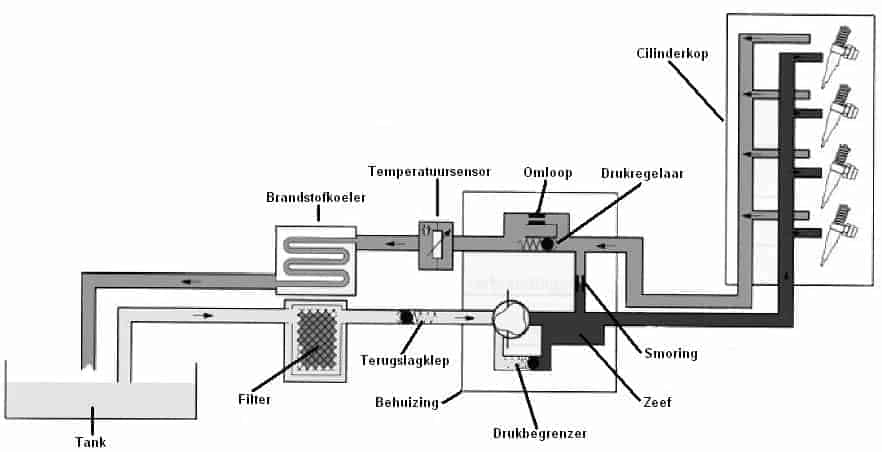

Fuel supply pump:

The fuel supply pump is a vane pump with spring-loaded vanes. It is positioned between the fuel filter and the injectors. The camshaft drives the pump, which contains a pressure relief valve limiting the feed line’s pressure to 7.5 bar. A valve in the pump maintains the unit injectors’ return line pressure at approximately 1 bar.

Modified distribution:

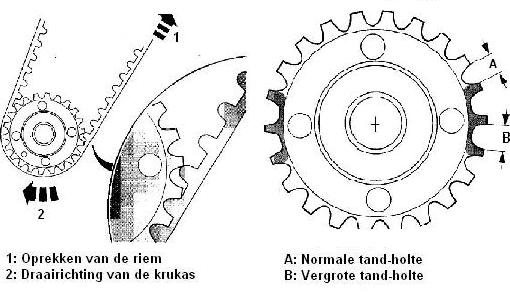

Given that pressure in unit injectors can reach approximately 2000 bar, the engine’s distribution system faces additional strain. To prevent belt breakage, several measures are implemented:

- The crankshaft gear has slightly larger tooth gaps at two locations. When the unit injector builds high pressure, the timing belt stretches, increasing the pitch of the teeth. This is compensated by enlarging the tooth gaps at two points.

- The timing belt is widened to increase its strength.

Fuel cooler:

The fuel cooler’s function, as the name suggests, is to cool the fuel. It is located near the radiator or under the vehicle. There is continuous fuel flow throughout the system. Fuel returning to the tank is significantly heated by the engine’s cylinder head. The fuel cooler cools the return fuel going back to the tank.

Related pages: