TPMS Introduction:

TPMS (Tire Pressure Monitoring System) is a safety system developed in the 1990s for vehicles equipped with run-flat tires. The TPMS warns the vehicle driver when the tire pressure becomes too low. The system activates at 0.5 bar. In the case of a flat tire, the driver will be informed in time before a dangerous situation arises.

There are different versions of TPMS:

- Passive: uses the ABS sensors in the vehicle.

- Active: uses pressure sensors in the tires.

Passive TPMS:

By measuring the speed at which the wheels rotate, a pressure loss in a tire can be detected. The wheel speed is measured by the ABS sensors. The tire pressure is not measured in this case. When a tire becomes underinflated, its rolling circumference decreases. The wheel spins at a slightly higher speed. The computer recognizes the increase in speed as a pressure loss.

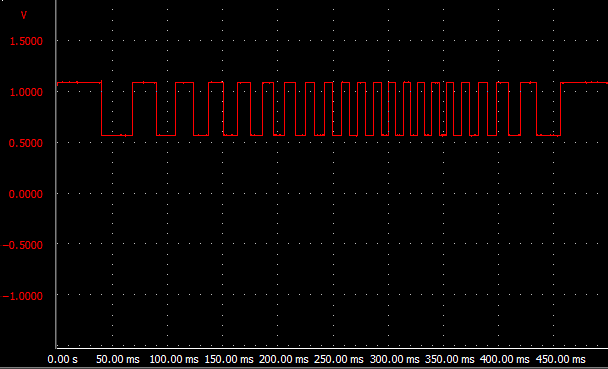

In the image below, the FM signal (Frequency Modulation) of an ABS sensor is measured. This signal is generated based on the wheel’s rotation speed. If one of the four wheel sensors sends an aberrant signal, the computer will identify this as a low tire pressure.

During driving, the system considers various conditions; bouncing or cornering does not affect the system’s operation. The warning light will not illuminate immediately after detecting a difference in wheel speeds. The check is carried out over a longer distance. If the deviation occurs over this specific distance, the system will activate the warning light.

Changing tire pressure also affects the system. After inflating the tires, slight rotational differences between the four wheels may occur. Therefore, the system must be reset or initialized after changing the tire pressure. The initialization can be performed by selecting it in the onboard computer menu or by pressing the dashboard button with the tire icon (see image).

The button often needs to be pressed for a few seconds to reset the TPMS. An icon will usually appear on the dashboard and then disappear after a few seconds. This indicates that the system is ready for use again. The system will automatically recalibrate during driving; wheel speeds are recorded over a long distance. Thus, the system is reliable again after traveling a few miles.

If the system is reset while a warning light is on, the system will recalibrate based on the current wheel speeds. The flat tire will no longer be detected.

Active TPMS:

Active TPMS uses pressure sensors in the tire. These TPMS sensors continuously send information about tire pressure and temperature to the computer via FM frequency. The system can detect a flat tire even when the vehicle is stationary. Some systems even monitor the spare wheel’s tire pressure.

Since active TPMS monitors tire pressure, it positively impacts fuel consumption, tire wear, and road safety; it ensures that drivers remember to check tire pressure timely.

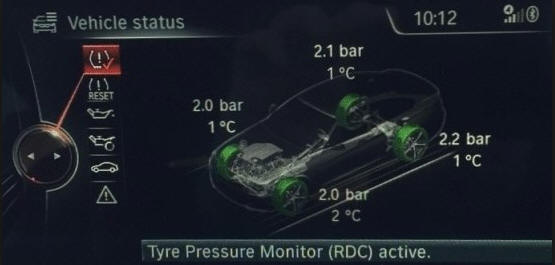

This is possible because pressure sensors in the tires continuously transmit the tire pressure to the control unit. The control unit checks if the pressure remains constant. Only when the tire pressure drops does a warning light appear on the instrument panel. Nowadays, tire pressure is often displayed graphically on the onboard computer display. This is only possible when the TPMS is equipped with EZ sensors. This is explained in another paragraph on this page.

The image shows a mounting overview of an EZ sensor. This is a widely used TPMS sensor that can be installed in any rim. The standard valve is replaced by this sensor. The sensor has a built-in battery lasting about 10 years.

The EZ sensor can be easily installed in the rim by fastening the two parts (the sensor and the valve) together with screws.

The TPMS sensors transmit tire pressure and temperature to the control unit. Modern, advanced systems make this data accessible to the driver by displaying it graphically. This way, the driver can neatly monitor tire pressure.

The display will show the location of the flat tire along with the measured pressure. The driver can decide whether to continue to the garage or stop immediately because the tire is flat. Tire pressure should never fall below 1.0 bar.

Replacing tires requires extra attention. Pressing the bead into the deep bed of the rim can cause the tire to move against the TPMS sensor, potentially breaking it. Therefore, the valve location must always be considered. It should be avoided at all times that the tire presses against it at that location.

Learning TPMS Sensors:

When wheels are swapped from left to right or front to back, the position of the TPMS sensor changes. The computer must know where the sensors are located. If the sensors are not properly learned, the tire pressure warning light for the left front wheel might turn on, while the right rear tire is flat. After replacing tires or changing wheel positions, the sensors must be learned. The method to learn the sensors varies by manufacturer.

Every sensor has a learning code:

- A = automatically learns while driving.

- O = learns via OBD using diagnostic equipment.

- S = instructions are in the user manual.

The location of sensors that automatically learn while driving is determined using several data points. During acceleration, braking, and steering, the wheels move at different speeds relative to each other. During cornering, the wheels on the inside turn slower than the wheels on the outside, and during acceleration, the wheels on the driven axle speed up slightly more than the undriven wheels. This is due to maximum allowable wheel slip caused by tire deformation.

During the trip, sensor locations are determined, often showing progress in percentage.

Some sensors must be learned with diagnostic equipment. There are several different types. For all types, a read and programming computer must be held close to the respective TPMS sensor. The correct position must be selected beforehand in this computer. After the computer makes a wireless connection with the sensor, the correct data is entered into the sensor. A test drive is then required to activate the TPMS system. The computer is shown in the image.

There are also variants where a read and programming computer is connected to the diagnostic computer, which in turn is connected to the car via the OBD connector. Values are stored in both the TPMS sensors and the car’s control unit. In most cases, a test drive is not needed; the monitoring system is immediately active.