Introduction:

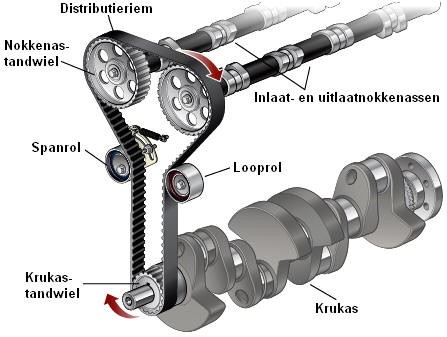

The timing primarily drives the camshaft, possibly the water pump and/or fuel pump in a diesel engine. The water pump can be driven by the timing belt, but also by the serpentine belt. Nowadays, many manufacturers even use electrically driven water pumps. The timing can be driven in different ways. These are described further down the page.

Timing:

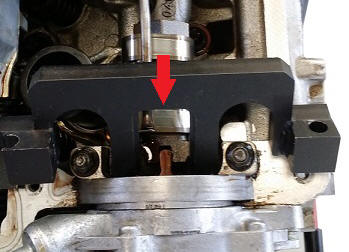

It’s important that the timing is set correctly. When installing or removing the belt or chain, it’s necessary to set the marks on the crankshaft, camshaft, and sometimes the diesel engine’s fuel pump to the zero point (timing). This is indicated with marks on both the engine block and the gears or pulleys, or the only way to set the timing is by using locking tools. Special locking pins can prevent the gears from rotating unintentionally during the replacement of the timing belt or chain.

After installing the belt, the tension must be checked and adjusted. This can be done with a tensioner pulley with a hydraulic tension element or a manual adjustment option. With a timing chain, the tension is automatically regulated by a hydraulic chain tensioner, which adjusts the tension based on oil pressure.

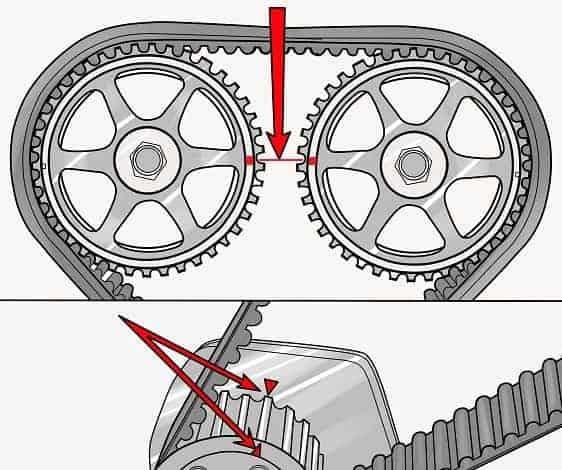

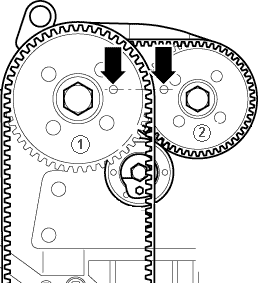

The image clearly illustrates what is meant by timing. At the top are two camshaft gears with (red) markings. In reality, these are often two notches machined into the gear. According to the instructions, these should be opposite each other (the left gear at 3 o’clock and the right gear at 9 o’clock).

The crankshaft gear also has a marking, often a notch as well. The marking point should align with the mark on the engine block. If the markings on the crankshaft and engine block are opposite each other, but the camshaft marks are 180° (half a turn) out of alignment, the crankshaft should be turned another full rotation. Each camshaft gear has twice as many teeth, so when the crankshaft makes two turns, the camshafts turn one rotation.

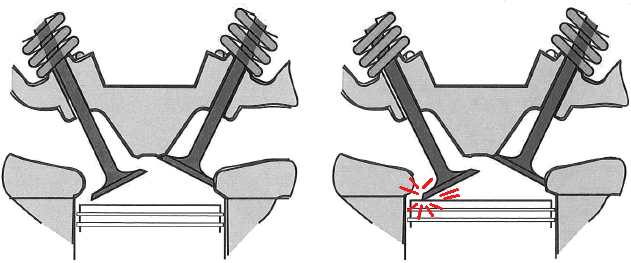

If the timing is not set correctly, the valves will open and close too soon or too late. This can lead to poor starting, rough engine running, and power loss. In the worst case, where the timing belt is off by one or more teeth from the zero point, the pistons can strike the valves. This often results in severe engine damage. In some engines, engine damage can occur if the timing is off by just one tooth, so pay careful attention during installation.

Timing Belt:

A timing belt lasts (depending on the type of engine) approximately 60,000, 90,000, 120,000, 180,000, or sometimes even 250,000 miles. Besides mileage, there’s also a specific time limit, e.g., a maximum of 4 years. As the belt ages, it can dry out or, in the worst case, snap, causing the belt to eventually break. The advantages of choosing a timing belt include:

- Cost-effective

- Does not need lubrication like a chain and gears do (nowadays, timing belts combined with engine oil are used, such as by Ford).

- Lightweight

The disadvantages of a belt include the need for periodic replacement and susceptibility to oil or coolant, which can leak from the crankshaft and camshaft seals or the water pump, if mounted within the timing section.

Timing Belt with Separate Camshaft Belt:

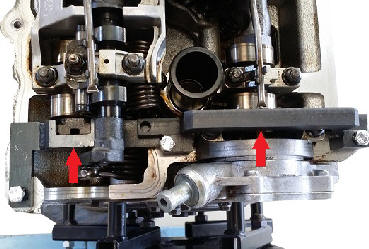

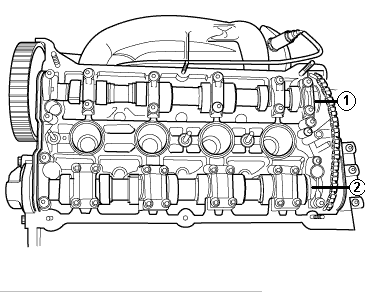

The image below shows an engine with a dual camshaft, driven by two timing belts. The camshaft gear (1) is directly driven by the crankshaft via the large belt. At the back of the pulley of gear 1, there’s a small gear over which the rear belt runs. This rear (small) belt drives the camshaft gear (2). The small belt requires a separate tensioner. This is usually applied in four-cylinder engines with 16 or more valves (i.e., 4 or more valves per cylinder).

Timing Chain:

A timing chain is virtually maintenance-free, unlike a timing belt that has a replacement interval. Some manufacturers have returned to using chains after improvements in noise and friction. A timing chain can last for the life of the engine. The tensioners used often rely on hydraulic pressure and spring force, so the tension of the chain doesn’t need regular checking.

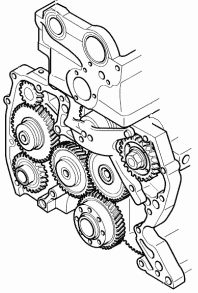

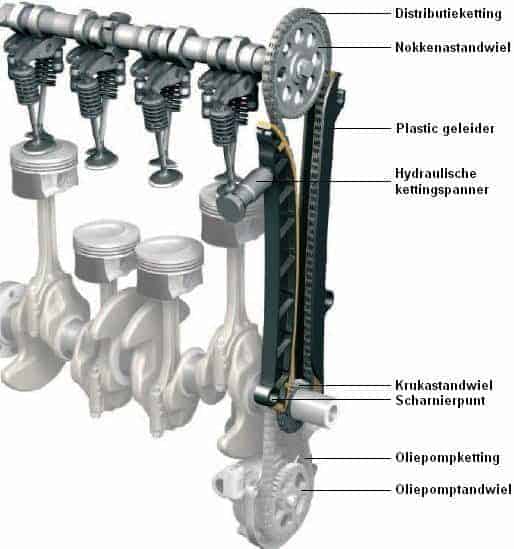

The image below shows an engine with a single camshaft equipped with a timing chain. The crankshaft gear drives the camshaft gear using the timing chain. The chain slides along the plastic chain guide, lubricated by engine oil. The hydraulic chain tensioner presses the plastic chain guide against the timing chain. The guide pivots on the hinge point at the bottom. This keeps the chain tight. There should be no slack on the chain, or it may rattle. A strong spring in the hydraulic chain tensioner ensures the chain remains tight even when the engine is off. When the engine runs, the oil pressure in the chain tensioner helps press the tensioner more firmly against the guide.

The oil pump gear is driven by a separate oil pump chain. The operation of the oil pump with a separate chain is described on the lubrication system page.

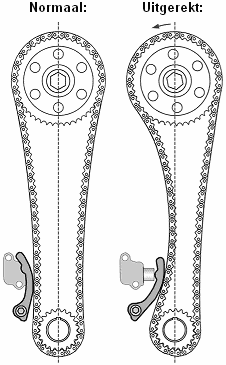

A timing chain can become longer, resulting in an elongated chain. Every chain becomes slightly longer as it ages, usually within tolerances. However, a chain can stretch enough to cause malfunctions. Possible causes of a stretched chain include:

- The material of the chain affects its lifespan.

- Driving at low RPMs, causing additional engine vibrations.

- A very sporty driving style with frequent acceleration.

- Aged engine oil due to infrequent changes.

The following symptoms indicate a stretched timing chain:

- Irregular engine running due to incorrect valve timing (valves no longer open and close at the right moment)

- The malfunction indicator lamp (MIL) may illuminate. An error code related to incorrect timing between the crankshaft and camshaft may be present.

- Rattling noises after starting the engine. This can occur due to slack between the chain and guide while the chain tensioner fills with oil to remove the slack. After the tensioner further tightens the chain, the rattling noise may disappear but could worsen over time as the tensioner extends outward.

- Rattling noises during engine operation. If a consistent rattling noise from the timing chain is audible, the tensioner may be fully extended with slack still between the chain and guide. This indicates you should not continue driving, as the risk of the chain jumping over the gears is high, leading to severe engine damage if pistons strike the valves.

When the chain rattles, it strikes the plastic guides. Particularly in older guides where the plastic has hardened, pieces of plastic may break off. The chain now has more space on the guide, and the broken plastic piece can fall into the oil pan, blocking the oil screen and the oil flow to the pump, resulting in low oil pressure and lubrication issues, ultimately leading to catastrophic engine damage.

Multiple Timing Chains:

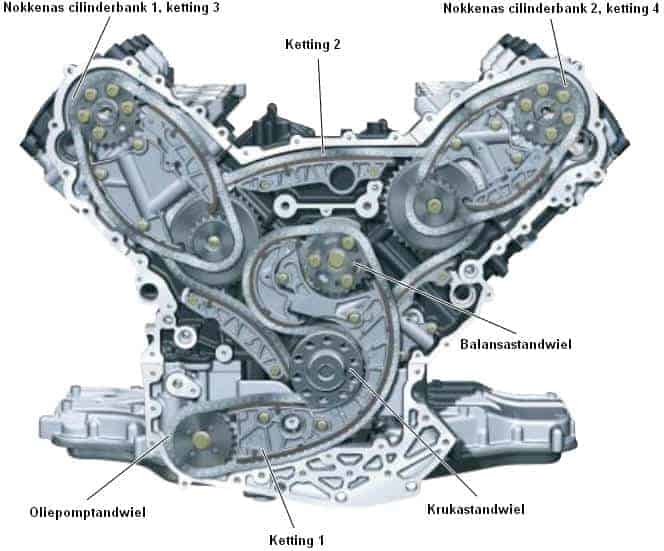

An engine may have multiple timing chains. In the V-engine shown, there are four separate chains. Chain 1 drives the oil pump and balance shafts. Chain 2 connects with the crankshaft and the camshaft drive gears. Chain 2 drives chains 3 and 4, which, in turn, drive the camshaft gears. Each chain is tensioned by its own chain tensioner.

Assembly Overview of a Timing Chain of a Volkswagen Engine:

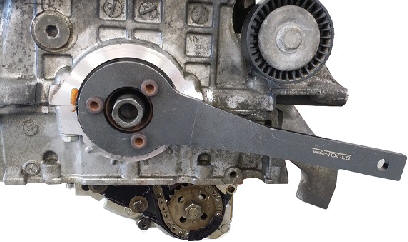

The image below shows a Volkswagen engine with an exposed timing case. The upper and lower timing covers have been removed, attached with sealant and about 25 bolts. The lower timing cover also features the crankshaft seal. The lower cover is also mounted to the oil pan.

When replacing the timing chain, the crankshaft must be locked by screwing a special bolt into the engine block. The crankshaft should be rotated until the crank journal contacts the bolt, placing the crankshaft in the correct position.

The camshaft should be locked by inserting a specialized tool with a protruding section into a groove at the rear.

Assembly Overview of a Timing Chain of a BMW Engine:

The image shows a timing cassette of a BMW engine. This BMW engine does not have covers that need removal for chain replacement. The timing cassette must be lifted out of the engine as a whole. The process is briefly described below. Several disassembly and assembly steps are not shown, as this is not a repair manual but intended to provide insight into the operation and assembly. Always refer to the repair manual for tightening specifications!

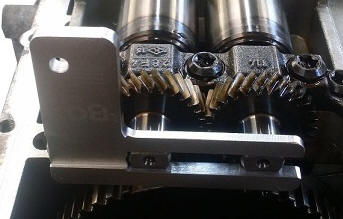

The pictured timing cassette comprises the timing chain, a plastic guide, a crankshaft gear, and two (adjustable) camshaft gears. For assembly, the guide must first be assembled as shown below.

With the chain tensioner and valve cover removed, and the bolts of the guides, crankshaft gear, and camshaft gears demounted, the entire cassette can be lifted out.

Before securing the camshaft gears, the impulse wheels must be set in the correct position by mounting a tool. The protruding points in the tool are inserted into the holes of the impulse wheels, ensuring they are positioned correctly.

Since the crankshaft gear and the gear for the balance shafts are aligned, the balance shafts must be fixed before the crankshaft bolt is tightened. If this is not done and the balance shafts are misaligned, the engine vibrations will increase instead of decrease.

After the crankshaft bolt is removed, the balance shafts will sink to their lowest point, increasing the risk of their misalignment rather than remaining perfectly aligned.

Once the crankshaft, camshaft, and balance shafts are fixed, the crankshaft flange can be inserted. The crankshaft bolt can be turned a few rotations but should not be fully tightened at this stage.

Before tightening the crankshaft bolt to the specified torque, the chain guide must first be pressed against the timing chain with a certain force to achieve a specific pre-tension. This can be done using a special tool mounted in the chain tensioner’s hole. By tightening it with a prescribed torque, the timing chain is sufficiently tensioned. Now, the crankshaft bolt can be tightened.

Always use a special tool to tighten the crankshaft bolt.

Once the bolts of the camshafts, guides, and crankshaft are tightened, the hydraulic chain tensioner can be mounted.

After securing and removing the special tools, the crankshaft should be rotated two turns clockwise. The timing must be checked again. If incorrect, the adjustment procedure should be repeated.

Combination of Belt and Chain:

The image shows an engine with a dual camshaft driven by both a belt and chain. Camshaft 1 is driven by the timing belt (left). The crankshaft drives this belt. The timing chain provides the drive for camshaft 2.a0

Gears:

Some engines only use gears for timing. The major advantage is that it’s completely maintenance-free and eliminates issues like belt aging or improper belt or chain tension. The significant disadvantage is that it produces a lot of noise. The helical gear teeth dampen some noise, but it is still noisier than a belt or chain. This is also a key reason why this type of timing isn’t frequently used.