Introduction:

Every internal combustion engine (gasoline/diesel) is equipped with a starter motor. This starter motor ensures the engine gets going. The pinion gear of the starter motor engages with the flywheel’s ring gear, causing the flywheel to move. An engine must reach a certain cranking speed to initiate the four-stroke process (intake stroke-compression stroke-power stroke-exhaust stroke). The cranking speed must be high enough for the engine to start.

A starter motor is a direct current motor, which is directly connected to the battery with a thick positive cable. This is done because very (high) powerful currents (and thus heat) flow through it. The starter motor converts electrical energy into mechanical energy.

Operation:

The starter motor is always mounted to the flywheel. When the starter motor is engaged, the pinion gear (rotating via the bendix) engages with the teeth of the flywheel. The flywheel then starts rotating. There are two electrical connections on the starter motor; one for the signal wire from the ignition switch (terminal 50) and one for the positive cable from the battery (terminal 30). Sometimes the connection from the ignition switch is made via a plug connection instead of a screw connection (see image below).

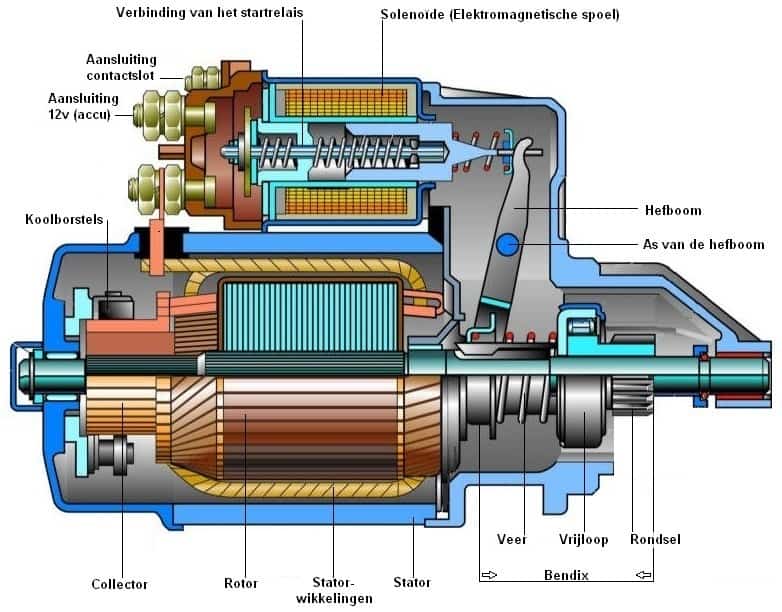

When the ignition key is turned to the start position, 12 volts are applied to the ignition switch connection (terminal 50) of the starter motor. This signal energizes the solenoid, allowing the current from the 12v terminal to flow through the coils. The solenoid functions similarly to a standard relay; a small control current creates a large main current. The solenoid is only larger because it handles very high current levels. When the solenoid is energized, the starter motor begins to turn.

Solenoid:

A solenoid is an electromagnetic component. When current flows through the solenoid, it becomes magnetic. This magnetic action can mechanically move a component, similar to a frequently used relay that operates, for example, the headlights and windshield wipers. In this case, the two connections of the start relay are drawn towards each other by the magnetic action.

When the engine is started, a small control current reaches the “ignition switch connection.” In the solenoid, the voltage from the “12v (battery) connection” is then switched through. The brushes transfer the voltage to the commutator. The north and south poles in the rotor ultimately generate a powerful movement in the stator; the electric motor will rotate.

The lever is pulled to the left at the top by the solenoid. Due to the (blue) pivot point, the lower part of the lever will move to the right. This action pushes the pinion gear into the flywheel ring gear with a rotating movement. Consequently, the rotor will spin, eventually setting the flywheel in motion. The car’s internal combustion engine will be driven at a certain speed (e.g., 400 rpm). The car’s engine management system ensures, among other things, the delivery of the correct amount of fuel during starting, so that the engine will start after a few crankshaft revolutions.

Bendix:

The assembly of the spring, overrunning clutch, and pinion is called the bendix. This bendix moves horizontally (in the image from left to right). It also ensures that the pinion makes a rotating movement as it moves outward. This prevents the teeth of the pinion from aligning directly with the teeth of the starter ring, avoiding a situation where the pinion gears cannot engage with the starter ring but instead hit against the flywheel teeth.

Once the engine has started, the pinion is retracted. This sometimes happens with a screeching sound. Cleaning and lubricating the bendix can temporarily resolve this issue. It is not damaging, just annoying.

Overrunning Clutch:

When the internal combustion engine starts, it will run at a higher speed (e.g., 800 rpm). This is double the speed at which the starter motor runs. At the moment the engine starts, the pinion is still engaged with the engine’s flywheel. This causes the pinion to also rotate at twice the speed. To prevent damage to the starter motor, an overrunning clutch is mounted for the pinion. The overrunning clutch ensures that the engine cannot drive the starter motor rotor; therefore, the starter motor will not rotate at the engine speed of 800 rpm.

The overrunning clutch can be seen as two rings connected by bearings. The outer ring can rotate in only one direction (for example, counter-clockwise). When the direction of movement reverses (clockwise), the overrunning clutch ensures that the outer ring locks. The inner and outer rings are then connected. Only when the outer ring rotates counter-clockwise again, will movement between the two be possible.

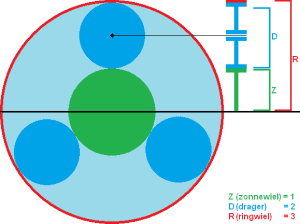

Planetary Gear System:

Certain starters are equipped with a so-called planetary gear system, also used in automatic transmissions. This gear system provides a different gear ratio and is often placed before the bendix. By reducing the pinion’s speed (relative to the rotor), torque is increased. An electric motor has its highest torque at a low speed. With a planetary gear system, a larger torque (hence more power) can be transmitted to the starter ring at a lower speed. See this page for an explanation of the planetary gear system.

Possible Starter Motor Defects:

- When turning the key in the ignition, nothing happens or only a ‘click’ sound is heard:

This may be due to a dead battery. When the board voltage is too low, the solenoid may be energized (resulting in a ticking sound), but the voltage is too low to drive the rotor. If the battery voltage is fine (at least 10.5 volts) and the starter motor still does nothing, the solenoid may be “stuck.” The lever is not actuated, resulting in no operation. By giving the starter motor casing a gentle tap with a hammer (and possibly a screwdriver), the mechanism will often be released, allowing starting again. This is, however, a problem that will surely reoccur in the future, so it would be time to make an appointment at a garage or refurbishment company. - A very loud screeching sound is heard during starting:

The bushings are defective and need replacement. Refurbishment companies specializing in alternator and starter motor rebuilding are experts in this area. - The starter motor slips briefly during starting (accompanied by a grinding sound), then spins briefly again and slips once more:

The flywheel’s starter ring is likely damaged. If the teeth are worn down, the pinion gear teeth of the starter motor slip over them. Possible causes include accidentally operating the starter motor when the engine is already idling, or frequent starting (such as with a driving school car or a courier’s vehicle that is started multiple times a day for years). - Noise after the engine has started:

The possible cause of this is the bendix getting “stuck.” This is audible for about one to two seconds after releasing the ignition key. The bendix is described above.