Introduction:

Shock absorbers increase ride comfort and improve road holding. Their purpose is to absorb the shocks from driving over uneven surfaces.

Simple example of their operation: If a thin leaf spring is clamped at one end in a vice, bent, and then released, the spring will start to oscillate. Thus, it will deform repeatedly at its own frequency. This is the same with a car’s coil spring.

When you drive a wheel over an obstacle on the road, the spring deforms and vibrates. This vibration can be amplified at a subsequent obstacle, causing it to rebound again. Since the wheel follows the movements of the spring, it will continually bounce up and down. The shock absorbers’ task is to dampen the spring vibrations as quickly as possible. They convert motion energy into heat.

A shock absorber does not affect the height of the vehicle. A worn shock absorber will result in poor driving performance, but that will not be visible when a car is stationary in a parking lot.

Compression / Rebound Stroke:

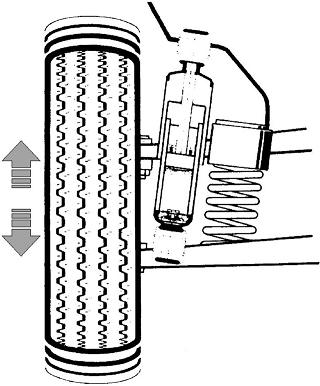

Compression Stroke:

During the compression stroke of the shock absorber, the piston moves downward relative to the cylinder. Oil below the piston flows through the bores to the space above the piston. The pressure on the oil is equal both below and above the piston. To compensate for the volume taken by the piston rod, oil flows from below the piston through the base valve into the reservoir tube. The compression stroke should proceed smoothly; it’s important to avoid the car being “lifted” over a bump if the compression stroke is too heavy. Damping is achieved during the rebound stroke.

Rebound Stroke:

In the rebound stroke, the piston moves upward relative to the cylinder. A certain pressure is exerted on the oil above the piston, causing this oil to flow through bores into the space below the piston. The resistance the oil encounters provides the force during the outward movement of the shock absorber. Oil flows from the reservoir tube into the space under the piston through the base valve to compensate for the volume occupied by the piston rod. The force required during the rebound stroke is greater than during the compression stroke.

With a loose shock absorber, it will be noticeable that it can be compressed easily but is difficult to extend again. If both the inward and outward movements were smooth, it would mean the damper is worn out.

Consequences of Worn Shock Absorbers:

- The braking distance becomes longer. When the wheel rebounds, contact with the road is broken, resulting in a discontinuous braking track.

- In a curve, it’s the friction between the tire and the road surface that keeps the car on the road. With worn shock absorbers, a car will skid much faster in a corner. Even on a straight road, the road holding is less good.

- The steering is less precise.

- The tire carcass is excessively stressed, which can lead to a blowout.

- Worn shock absorbers also cause typical tire wear, where the tires have large wear spots in random places and more tread in others.

Checking Shock Absorbers:

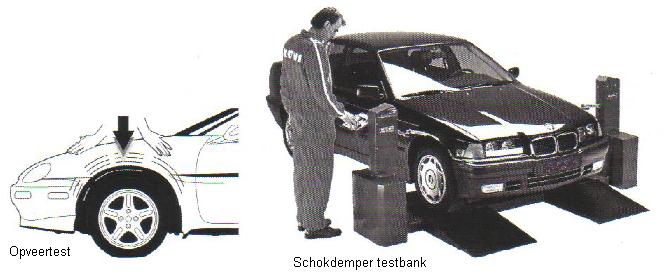

Bounce Test:

The overall performance of shock absorbers can be checked in the following way:

- Grab a sturdy part of the fender or similar (that won’t dent under exertion). Move it up and down with a smooth motion, so the vehicle bounces firmly in and out.

- Let go of the vehicle after it has cycled in and out a few times.

- The vehicle should bounce no more than 2 times; in-out and in-out again.

- If the vehicle continues to bounce until the body comes to a halt, the shock absorber is worn.

- If the vehicle can be bounced very far in and out so the wheel leaves the ground, the shock absorber offers no damping at all. Now what happens is the spring can oscillate freely without any damping in the rebound motion. The maximum spring travel is reached in a short time, causing the body to move further up and down. In that case, the wheel can leave the ground in the rebound motion. This last scenario is very dangerous. It can also occur while driving. The chance of an accident is greatly increased when driving on poor road surfaces.

Shock Absorber Test Bench:

The manual bounce test is not completely reliable. A better method to test shock absorbers is using a shock absorber test bench. The driving plates are unlocked from a certain height, causing the plates to drop slightly (about 8 inches). Based on the results of the vehicle’s rebounding, the computer can determine the extent of wear on the shock absorber for each wheel.