Topics:

- Video of running engine

- Measurement results

- Graphs

- Scatter plot

Video of the running engine:

In the previous stage, the engine was made functional on the MegaSquirt engine management system. The MegaSquirt ECU was programmed and properly set up using the TunerStudio software. This section presents a video that was recorded after the settings were completed. The video is divided into three parts:

- starting and idling;

- idling and showing components such as the modified intake manifold and ignition coil;

- increased RPM.

Measurement results:

The video shows that the engine starts well, idles smoothly, and the RPM can be increased to 3000 RPM without issues. To verify if the engine functions properly with the installed engine management system, it is essential to “log” all sensor values and actuator controls. This provides insights into whether the engine management system operates correctly under various operating conditions. Therefore, it was decided to expand the existing TunerStudio software with a package that enables logging.

The achieved results are enumerated in this chapter and are displayed using graphs and scatter plots. These are created through the logging function in TunerStudio. After all adjustments were made, the engine ran for a few minutes. This allowed the entire warming-up phase to be completed, the engine idled for a few minutes, and the RPM was raised to 3000 RPM for a few minutes.

Graphs:

Settings with TunerStudio are done with live data; the gauges on the dashboard show the current value. There is also an option to log the data. A log contains information from the sensors and actuators that are recorded over a specific period. Thus, the measurement results can be reviewed. This helps to determine if the data is processed correctly and if the engine is operating properly.

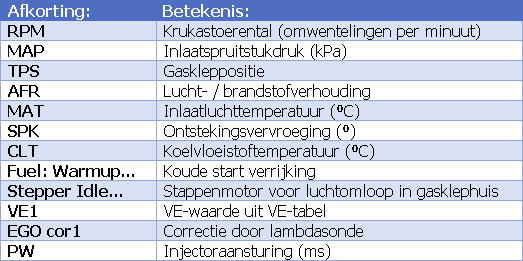

The images below show the measurement results recorded during testing. The abbreviations are explained in the table.

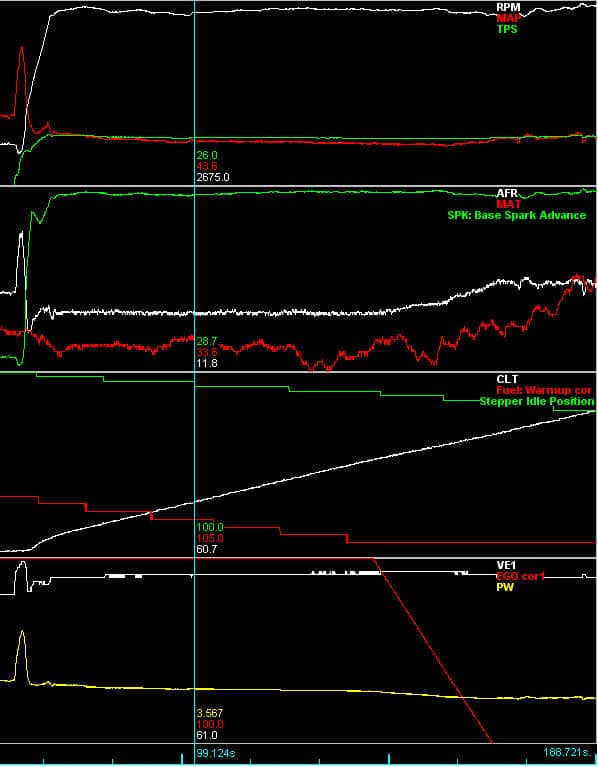

The measurement results are divided over four screens that have the same time span. The vertical, blue line serves as a cursor moving from left to right across the screen. In the upper screen, the crankshaft RPM, intake manifold pressure, and throttle position are visible. The RPM increases from idle (400 RPM) to 2675 RPM. The time between opening the throttle and increasing the RPM is seen as a negative dip in the RPM line. At that moment, the intake manifold pressure drops (peak) and the throttle position sensor value rises. The throttle position sensor value is used to determine acceleration enrichment; acceleration requires a richer mixture for a short time.

The second screen displays the AFR. At the cursor’s position, the AFR is 11.8, indicating a rich mixture. The intake air temperature initially hovers around 20°C but later rises to 33.6°C. The green line indicates the ignition timing advance; at a constant RPM of about 2500 – 2675 RPM, the ignition advance ranges from 28.7 to 30.0 degrees.

The third screen shows the increasing coolant temperature. This decreases the cold start enrichment, and the stepper motor becomes more closed.

The bottom screen displays volumetric efficiency, which is 61% at the cursor’s position. It also shows the lambda sensor correction and injector control. The injector is controlled for 3.567 milliseconds at the cursor’s position. This is the actual injection time.

The following measurement results were recorded a few minutes later.

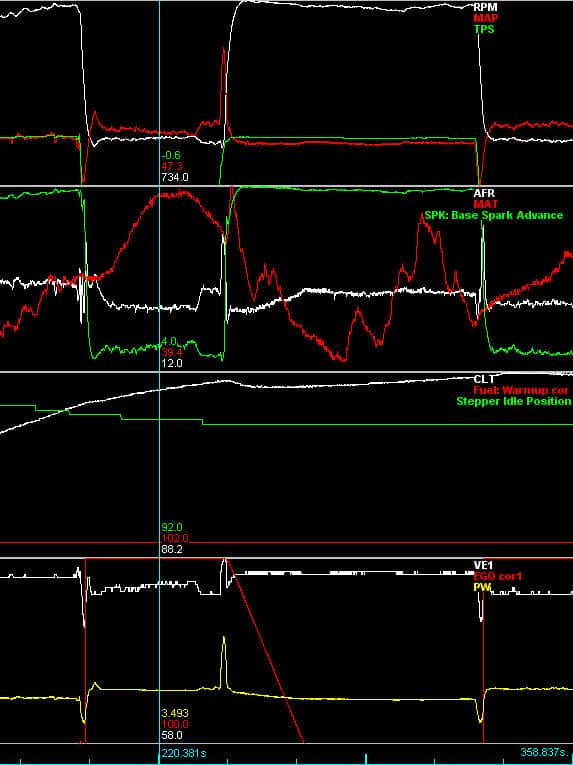

The next image shows the measurement results of the situation where the RPM drops from 2675 RPM to the idle speed of 734 RPM and then rises again. When the RPM decreases, the acceleration enrichment stops; the TPS detects that the throttle is back in its initial position. Closing the throttle causes a significant vacuum in the intake manifold. This is visible as a negative dip in the MAP value. When opening the throttle, the vacuum disappears; the MAP value rises a few milliseconds.

The ignition advance at idle drops from 28.7 to about 4 degrees before TDC.

Upon reaching a temperature of 90°C, the stepper motor reaches its maximum position; the idle control valve is fully closed.

Fluctuating RPMs also impact the injection time; during deceleration, the injection time drops to 1.3 ms (not shown in the graph). When the RPM increases, the control time briefly increases to 7 ms. At a constant, elevated RPM, the injection time decreases again to about 3.5 ms.

Scatter Plot:

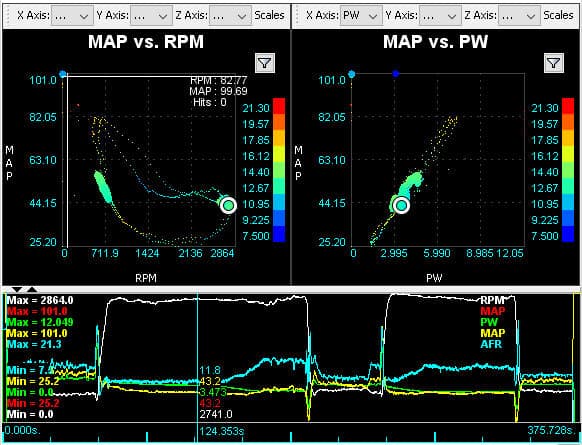

The entire cycle is represented in the image in a so-called “scatter plot.” Two scatter plots are displayed side by side, with the total course shown in graph form below.

Clicking on a random spot in the graph results in a circle appearing in both diagrams. Clicking different areas in the graph reveals different locations in the scatter plots.

In this scatter plot, the left diagram shows the MAP value relative to the crankshaft RPM. The colored bar on the right of the diagram indicates the AFR.

In the left diagram, the AFR is approximately 12.67. This means that the mixture is rich at that moment. This can be explained by the elevated RPM with a low coolant temperature (see the coolant temperature course in figure 46). Additionally, the AFR in the top left ranges between 17.85 and 19.57; this is during deceleration, where no fuel is injected, resulting in a lean mixture.

The right diagram in figure 48 shows the MAP value in relation to the fuel injection. This shows the operating range.

With the positive outcome of the measurement results, the project has been successfully completed.