Control Engineering:

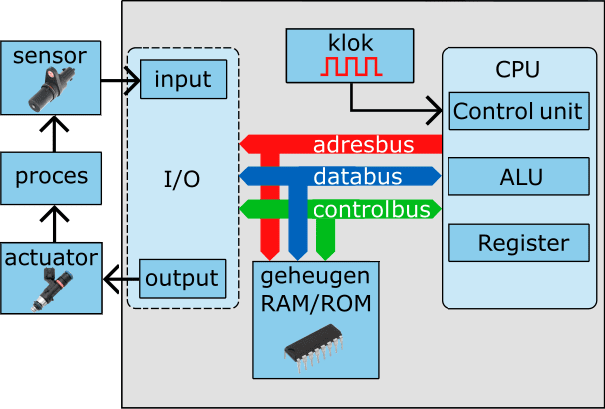

The ECU measures, controls, and regulates processes. The ECU receives information from sensors. A sensor converts a change in a physical quantity into an electrical signal. This sensor information enters the ECU via the input. Possible input signals come from:

- speed sensor;

- temperature sensor;

- load (vacuum) sensor;

- oxygen sensor.

The incoming information does not necessarily lead to immediate action. Only when a measured value deviates from the desired value can the actuator control be adjusted. The ECU then has a “regulating” function. Yes/no decisions are made via the preprogrammed computer program (ROM / Flash memory).

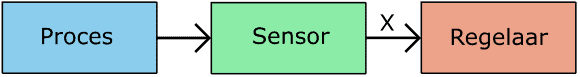

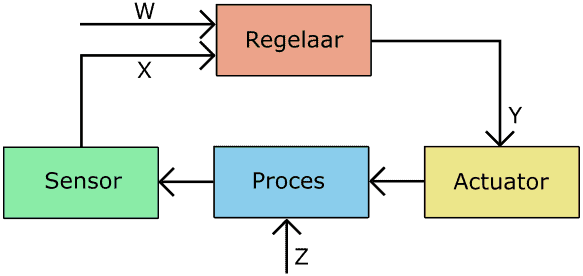

Measuring: the sensor measures a physical quantity and converts it into an electrical signal. This measured value (X) is sent to the controller. The measured value does not necessarily lead to immediate action; think of a constant temperature.

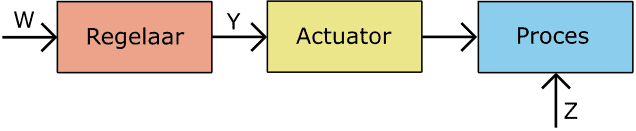

Controlling: the controller (ECU) controls an actuator. There is no feedback from a sensor, so the ECU does not follow the process course. Therefore, a malfunction in the process is not always recognized. An example of controlling is manually operating the horn (W); the ECU controls the horn (Y) upon operating the switch. The horn lacks a control function, so malfunctions (Z) are not detected.

Regulating: the controller can process a manual command (W) or a measured sensor value (X) into actuator control. The actuator causes a change in the process; for example, consider injection duration. More injection means a richer mixture. The oxygen content is measured by the lambda sensor and sends this measured value (X) to the controller. When an unforeseen malfunction (e.g., a blockage in an injector) is present, it causes a change (Z) in the process. This deviation is also measured by the sensor, allowing the controller to adjust the process via the actuator control.

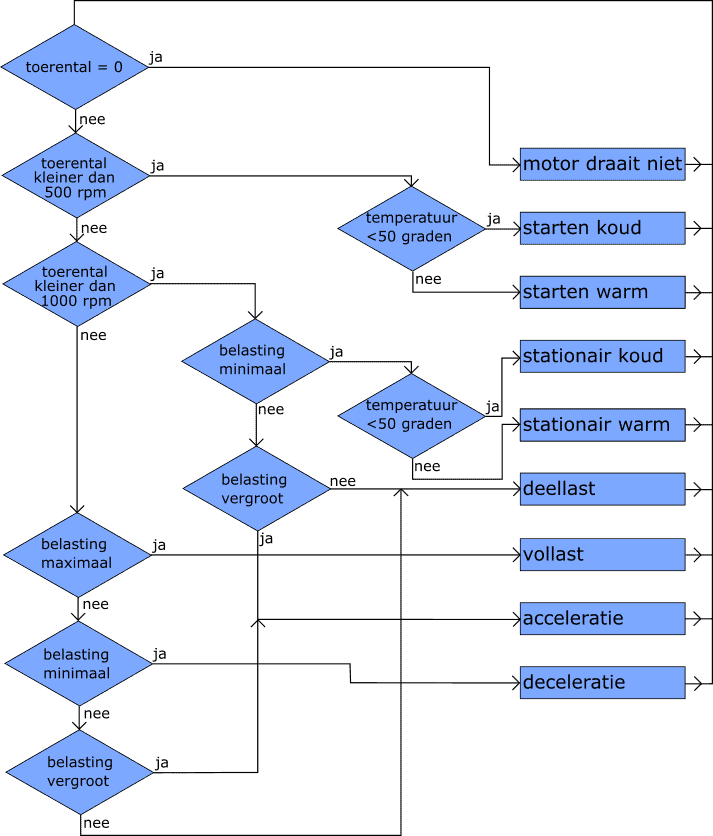

Process Control Based on Operating Conditions:

The engine management system of an internal combustion engine must optimally burn the mixture under all operating conditions. Determining the mixture composition and ignition timing are crucial in ensuring exhaust gas composition (emission), economy, and achieving the desired power.

Each operating condition has its own control technique:

- Cold start: the mixture is rich and the ignition is delayed;

- Warm start: the mixture is less rich than during a cold start;

- Cold idle: mixture is rich and idle speed is increased;

- Warm idle: mixture is less rich at a lower idle speed;

- Part load: stoichiometric mixture, speed range between 1500 and 4000 rpm, ignition timing is predefined, lambda control is active;

- Full load: mixture is enriched, load and speed are high;

- Acceleration: rich mixture, delayed ignition;

- Deceleration: lean mixture, advanced ignition.