Oxygen Sensor:

Every modern car with a gasoline engine and EOBD has 1 or 2 oxygen sensors mounted in the exhaust. Often a control sensor is located before the catalytic converter (a wideband sensor), and a monitoring sensor after the catalytic converter (step sensor). When only one oxygen sensor is present (before the catalytic converter), it is usually a step sensor. The step sensor is also known as a zirconium sensor. In the image below, the front and rear oxygen sensors of cylinder bank 1 are shown (numbers 1 and 2) and of cylinder bank 2 (numbers 3 and 4).

The oxygen sensor monitors the air and fuel mixture in the exhaust gases. The measurement data is sent to the engine control unit. The oxygen sensor is necessary for the catalytic converter to function, as it operates with a mixture that regularly switches between lean and rich. The control sensor actually “controls” the mixture composition; the engine control unit receives measurement data from the control sensor and adjusts fuel injection accordingly. When the mixture was too lean, more fuel is injected. In case of a rich mixture, the injector’s injection time will be shortened to make the mixture leaner again.

When a vehicle is equipped with two sensors, the step sensor registers the oxygen level in the exhaust gases after the catalytic converter; this checks whether the catalytic converter has properly converted the exhaust gases. If the catalytic converter is defective (e.g., when the internal parts are faulty or purely due to aging), the step sensor will recognize the poor functioning of the catalytic converter. The engine malfunction indicator light will then be activated. When the car is read, an error code will appear with information that the catalytic converter is not functioning properly. An oxygen sensor often lasts around 160,000 km. When an oxygen sensor is aged, the measurement results may be affected without the engine malfunction indicator light illuminating.

The page on injection systems explains how the mixture composition affects exhaust gases, power, and fuel consumption.

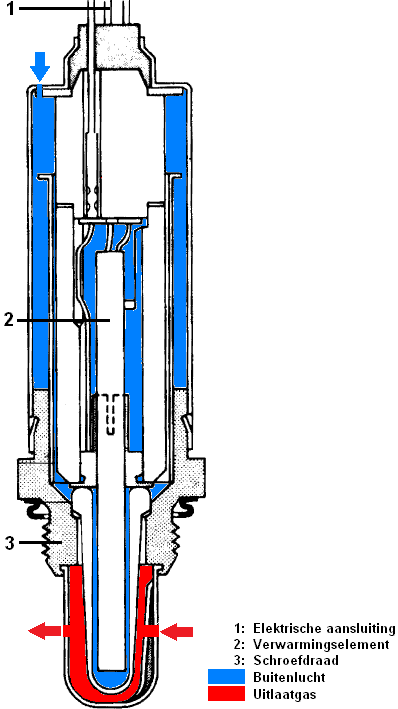

The oxygen sensor compares the exhaust gases with the outside air. Therefore, it is important that the outside air supply in the sensor is not blocked. If this hole is blocked and no (blue in the image below) air can enter the sensor, it will not work.

Heating Element:

Modern oxygen sensors are equipped with an internal heating element. This heating element ensures that the oxygen sensor can start measuring as quickly as possible after a cold start. The oxygen sensor only operates when the exhaust gases have reached a temperature of approximately 350 degrees Celsius. By internally heating the oxygen sensor, measurements can be taken when the exhaust gases have reached only half of the originally required temperature. Instead of several minutes, it can now be operated in a closed-loop situation in just a few seconds.

Wideband Sensor:

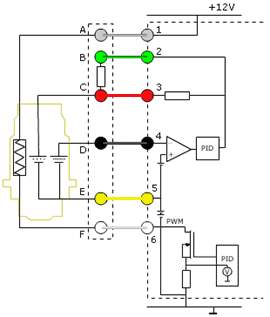

The wideband sensor has a larger measurement range than the step sensor. Even during full load, where the mixture is rich, the correct air/fuel ratio is registered and sent to the ECU. The measurement accuracy is not only high, but the sensor is fast and withstands high temperatures (up to 950-1000 b0C). The image below shows the diagram of the wideband sensor.

The wideband sensor must be at least 600 b0C to function properly. Therefore, a heating element is also used (between connections A-F) that heats the sensor after a cold engine start. The wideband sensor consists of a conventional zirconium sensor and a pump cell. The sensor is placed between connections D and E, and the pump cell between C and E. The output voltage of the zirconium sensor depends on the lambda values:

- Lean: 100 mV;

- Rich: 900 mV.

The pump cell in the wideband sensor tries to keep the voltage constant at 450 mV by pumping oxygen to or from the exhaust. In a rich mixture, the oxygen content is low, so the pump cell needs to pump a lot of oxygen to maintain the 450 mV voltage. In a lean mixture, the pump cell removes oxygen from the measurement cell. This changes the current direction used by the pump cell.

The current that occurs during pumping is measured. The magnitude and direction of the current are measures of the actual air/fuel ratio. In the control unit (the part to the right of the dashed line in the image above), the pump cell is operated. The voltage at point 4 depends on the value provided by the oxygen measurement element. This voltage reaches the negative input of the opamp in the control unit.

- Rich mixture: the voltage at the negative input of the opamp is higher than at the positive input. The amplifier is grounded, and the output voltage will decrease. A current flows from E to C.

- Lean mixture: the voltage at the negative input of the opamp is lower than 2.45 volts, so the amplifier is set to 4 volts, and the output voltage will increase. A current flows from C to E. The current direction is opposite to that in the rich mixture.

The control unit can determine the current strength by measuring the voltage drop across the resistor at connection 3. The magnitude of this voltage drop is the measure for the lambda value. Therefore, the voltage of the step sensor cannot be checked with a multimeter to verify if the sensor is still functioning correctly.

Step Sensor:

The step sensor has a limited measurement range. Older cars with only one oxygen sensor before the catalytic converter are often equipped with a step sensor as a control sensor. The step sensor generates a voltage based on the oxygen difference. This voltage ranges between 0.1 and 0.9 volts and can be measured with a multimeter.

Lambda values in a homogeneous and stratified combustion process:

Homogeneous:

In a homogeneous mixture, the lambda value is 1 everywhere. That means in a gasoline engine, the ratio of air to fuel is 14.7:1 (14.7 kg air with 1 kg fuel). Every engine can run homogeneously. If it is enriched, the lambda value will decrease, and if the mixture is made leaner, the lambda value will increase:

bb<1 = Rich

bb>1 = Lean

An engine will always oscillate between lean and rich to ensure the catalytic converter works effectively.

Stratified:

Engines with direct injection can operate stratified under partial load. A stratified combustion process means there are various air layers in the combustion chamber that are utilized during combustion. Near the spark plug, the lambda value is 1. Further away, the lambda value increases (is leaner, thus more air). This air provides an insulating air layer. In a stratified process, the injection timing is later than in the homogeneous process.

With stratified injection, the throttle valve can be fully opened, reducing the choking effect on the air. As the drawn-in air is less choked, it encounters less resistance, making it easier to draw in. Since the lambda value in the combustion chamber is still less than 1 during stratified injection due to the insulating air layer, it doesn’t cause combustion problems. During the stratified process, fuel consumption decreases.