Engine knocking:

Engine knocking occurs only in mixture engines (gasoline/gas). The knocking of the engine (also known as detonation or engine knock) is the auto-ignition in a gasoline or gas engine. When the engine knocks, the fuel is not ignited by the spark plug, but ignites itself at an earlier time. In this case, the mixture ignites while the piston is still compressing. The piston rises and the explosion already occurs. The piston force is now greatly opposed, which can cause significant engine damages (such as a hole in the piston). Engine knocking only occurs in the low RPM range.

Possible causes of engine knocking:

- The engine cooling system is not functioning properly: Due to the engine being extremely warm, the temperature in the combustion chamber increases more than usual. During the compression of the mixture, heat also develops, which can cause it to ignite prematurely.

- Wrong type of gasoline: When a car manufacturer specifies that gasoline with an octane number of RON 98 must be used, RON 95 should never be used. RON 98 has a lower tendency to ignite than RON 95. This means that 98 burns less quickly than 95.

If 95 is used, there is a high chance of engine knocking, because the temperatures in the combustion chambers rise higher than in other engines. The fuel then ignites earlier than it should. It may ignite when the piston is still compressing and the spark plug hasn’t yet fired a spark.

Therefore, 98 is suitable for higher temperatures and pressures in the combustion chamber. - Incorrect driving behavior: When driving up a steep hill at too low engine RPM, for example with a caravan or other heavy load, there is a high chance of engine knocking. The cooling is minimal, and the combustion pressure and temperatures are at a maximum. It is better to shift down a gear, (from 5 to 4) making the engine run at a higher RPM. Often less throttle is then needed, and the engine might even consume less fuel.

- Contamination: Incorrect driving behavior can also cause a lot of contamination in the engine. By always driving in short distances and/or always driving at low RPMs (shifting up too quickly so the engine never really gets going), a lot of engine contamination occurs. Due to the low RPMs, carbon residues stick to the valves and the piston head. When the engine is then heavily loaded, these carbon residues start to glow (like during a barbecue) and they take over the task of the spark plug. The fuel then ignites due to the glowing carbon pieces before the spark plug sparks, increasing the chance of engine knocking.

A turbo can also become defective in this way, as the glowing carbon residues can damage the material.

These cases often happen with “the new driving” where early shifting is advocated. In the city, driving at low RPM is certainly fuel-saving, but just like example 1, when driving in the mountains with a caravan, it can have fatal consequences for the engine and downshifting is actually more economical. Always driving quietly always causes problems with contamination. Especially with the newer generation engines with EGR and variable valve timing, etc. It’s good to occasionally rev the engine with a warm engine (e.g., up to three-quarters of the maximum engine RPM).

Knock sensor:

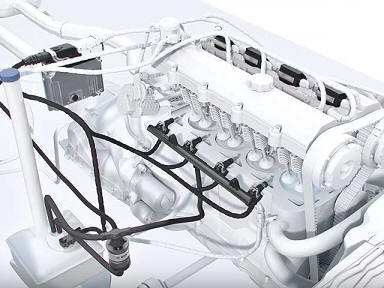

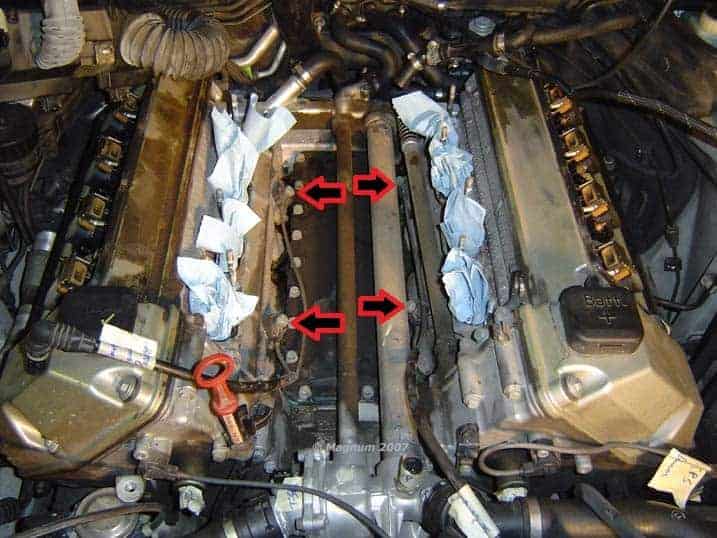

In new engines, knock sensors are increasingly being used. These sensors are mounted on the engine block. Often several are mounted, one sensor between every two cylinders. During engine knocking, a certain vibration frequency is created in the engine, which is recognized by the knock sensor. In this case, the engine control unit adjusts the ignition timing in steps of 3 degrees late. The knock sensor ensures the engine just doesn’t knock and just borders on the limit. The engine control unit will constantly advance the ignition timing of all cylinders in steps of 0.5 degrees to the normal value.

The picture below shows a V8 engine block on which 4 knock sensors are mounted. The tips of the arrows indicate the knock sensors. It’s somewhat difficult to see. The sensors are attached to the engine block with 1 small bolt. You can see the wiring of these sensors running forward.

Water injection:

To prevent engine knocking, water injection can also be chosen. The injected water vapor absorbs the heat in the combustion chamber. The temperature, and therefore the chance of engine knocking, decrease as a result. This is especially applicable with turbo engines that deliver a lot of power and therefore need to bea0wella0cooled.