Introduction:

In modern vehicles, the charging state of the alternator is adjusted to the conditions. The alternator is controlled by the engine ECU and receives signals for more or less charging. The alternator generates energy as a magnetic field is created between the rotor and stator. The larger the magnetic field, the more force is required to turn the rotor. Thus, generating a large amount of charging current requires energy and fuel.

- The idle speed can be increased when the battery is almost empty and cannot be adequately recharged;

- During maximum acceleration, the alternator is temporarily not controlled to use all the generated torque for propulsion;

- During deceleration (engine braking), the ECU maximally controls the alternator so that the vehicle’s kinetic energy is used to generate energy in the alternator. The indication of the maximum battery charge (12-volt system) is shown in the image.

The signal from the intelligent battery sensor is used to determine the battery’s state of charge. This is one of the most important data to determine to what extent the alternator should be controlled.

Intelligent Battery Sensor:

Modern vehicles are almost all equipped with a battery sensor, often known as an IBS (Intelligent Battery Sensor), current sensor, or battery monitoring. In this article, we will refer to the term “battery sensor”. The battery sensor works closely with the Battery Monitor System (BMS) in the vehicle. This is especially true for vehicles with a start-stop system. In these vehicles, the battery is repeatedly heavily loaded as the starter motor is activated multiple times per trip to start the engine. Therefore, vehicles that have a start-stop system often choose an AGM battery instead of a traditional lead-acid cell. An AGM battery is better able to withstand repeated discharging and charging.

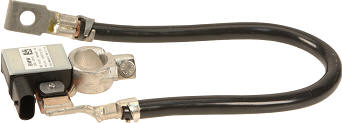

The battery sensor is integrated into the ground cable, which is attached between the negative terminal of the battery and a ground point on the body or chassis. On the battery sensor, there is a connector with two or more wires. One wire leads directly to the positive terminal of the battery, and a second wire is for communication.

Inside the housing of the battery sensor, there is a circuit board with a microprocessor and a controller that measures voltage, current, temperature, and time. The data from this Electronic Control Unit (ECU) is often transmitted via a LIN bus to the alternator and the body control module (BCM) or the engine control unit. Between the battery sensor and the BCM or engine control unit, there is usually the gateway to translate the LIN bus message into a CAN bus message. The paragraph “Diagnosis of the Intelligent Battery Sensor” further explores this.

The battery sensor monitors the battery’s condition and measures the following parameters:

- The battery voltage.

- The current with which the battery is charged and discharged.

- The temperature of the battery.

The battery sensor sends this data to the engine control unit or BCM. Using this data, the ECU (Electronic Control Unit) calculates the following:

State Of Charge (SOC) of the battery. By measuring the outgoing current to the consumers and the incoming current to the battery, it can be determined how much energy is still available in the battery.

State Of Health (SOH) of the battery. The battery voltage and discharge current are compared to assess the quality of the battery. During starting, a small gasoline engine may draw up to 60 A or a heavier diesel engine may quickly draw 120 A from the battery. The degree to which the battery voltage drops indicates how high the internal resistance in the battery is. If the voltage drops from 11.5 to 10 volts at a current of 60 A, this is acceptable. If the voltage drops from 11.5 to 8 volts at the same starting current, it indicates too high an internal resistance in the battery and replacement is necessary.

Parasitic drain during standstill. This detects a disturbance in the parasitic drain, for example by an unauthorized consumer. The driver receives a warning during the next trip if an increased parasitic drain is detected.

Components and Measuring Principles of the Battery Sensor:

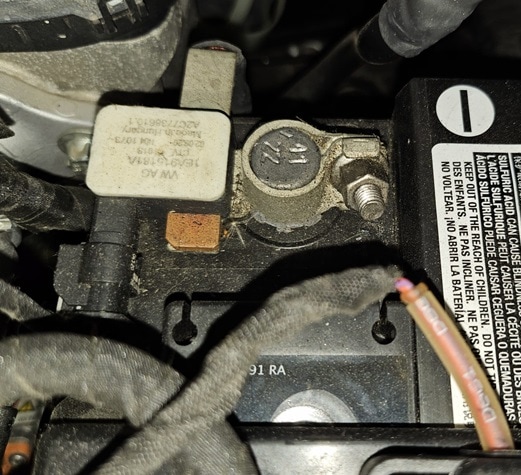

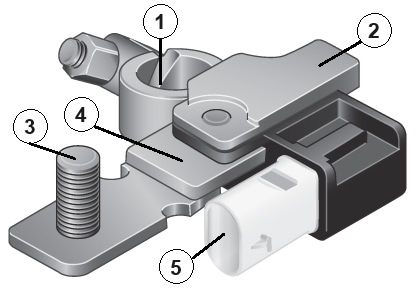

The housing of the battery sensor and the grounding terminal are often integrated into one unit. The ground cable can also form a unit with the battery sensor or be fastened with a screw connection. Inside the battery sensor, there is a shunt resistor with a very low resistance value. By measuring the voltage difference across this shunt, the current can be calculated. In combination with the battery voltage, the power with which the battery is charged or discharged can be calculated.

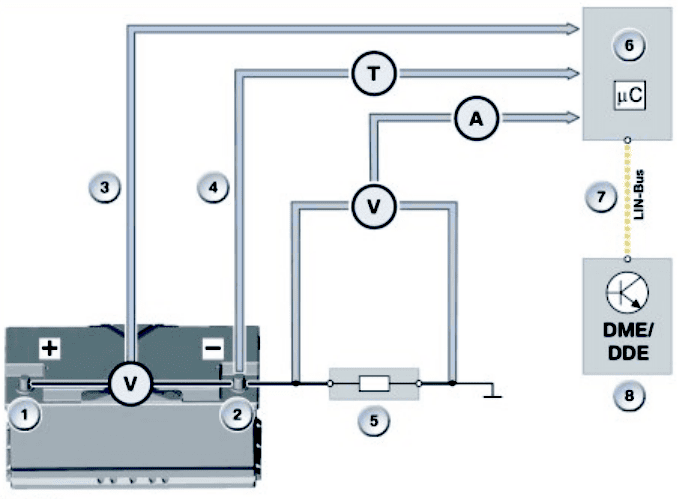

1. Terminal clamp grounding terminal;

2. Battery sensor;

3. Vehicle ground connection;

4. Shunt;

5. Connector for B+ and LIN bus.

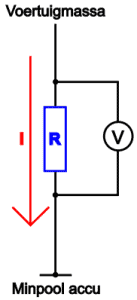

The shunt resistor is placed in series between the vehicle’s ground connection and the negative terminal of the battery. All current to and from the battery passes through this shunt. Due to the low resistance value, little voltage is consumed in the shunt.

The level of this voltage is converted into a current value in the microprocessor, together with the known resistance value of the shunt:

- A large voltage drop across the shunt indicates a large current.

- A low voltage drop indicates a low current.

The accompanying image shows a diagram where resistor R represents the shunt and current I the discharge current during the discharging of the battery. The voltmeter, placed parallel over the shunt resistor, illustrates how the measuring electronics in the battery sensor measures the voltage difference across this shunt.

The following image provides an overview of the locations where temperature, voltage, and current measurements take place.

The shunt resistor is denoted by number 5. The voltage difference (V) across the shunt is read as current (A). This data is sent via the LIN bus to the DME/DDE, which are the designations for the gasoline engine (DME) and diesel engine (DDE) of BMW.

1. Battery positive terminal;

2. Battery ground terminal;

3. Measuring battery voltage;

4. Measuring battery temperature;

5. Measuring current using a shunt resistor;

6. Microprocessor in the intelligent battery sensor;

7. LIN bus communication wire;

8. Engine control unit

Charging and Replacing the Battery:

The battery management system uses the battery sensor to measure the current flowing to and from the battery and to store this information in memory. When the battery needs to be charged or a jumper is used, it is important not to connect the charger directly to the battery terminals, but to the charging points. The battery sensor is located between these charging points and the battery terminals and can only measure the energy flow when the charger is connected to the charging points. If the charger is connected directly to the battery terminals, the BMS memory indicates that the battery is (almost) empty, while it is actually fully charged. The alternator will then overcharge the battery, causing the system to fail. The images below show a charger connected directly to the battery and to the charging points under the hood.

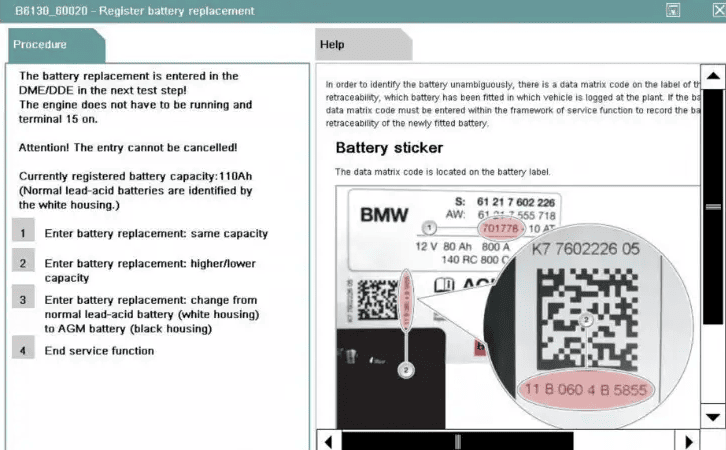

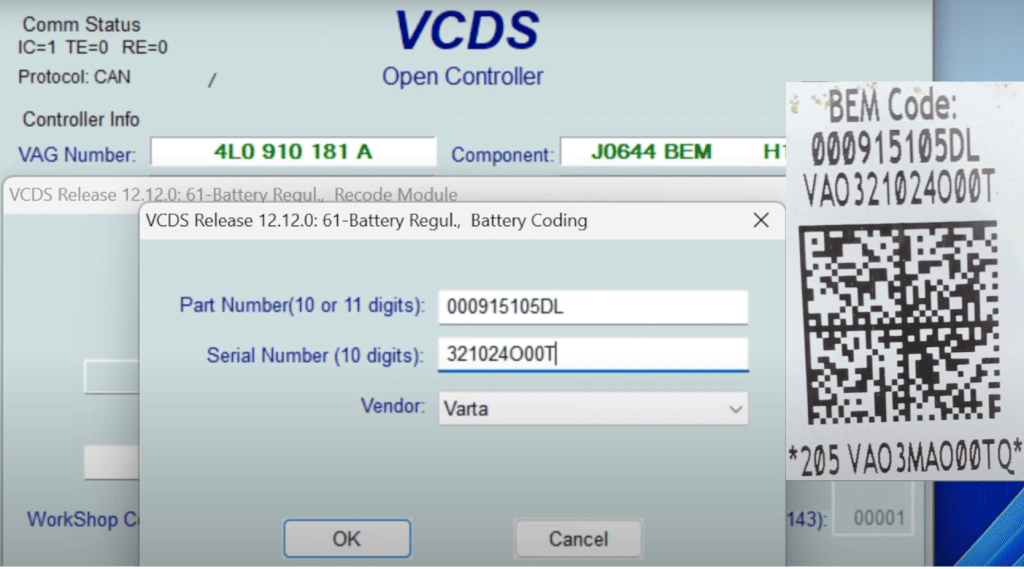

After replacing the battery in a vehicle equipped with a battery sensor, the battery must be registered. In the workshop, this is also known as “learning” or “coding”. The battery management considers:

- aging of the battery. The charging current may be increased for an older battery with increased internal resistance;

- the capacity and cold cranking amps of the battery.

During registration, the stored values of the battery, which have deteriorated over time, are erased. Even when an identical battery of the same brand and capacity and cold cranking amperage is installed, the replacement must be registered. Of course, the data of a battery with different characteristics must be communicated. This can be done by manually entering the capacity [Ah] and cold cranking amps [A], or by filling in the part numbers or serial numbers. With modern diagnostic equipment, the QR code depicted on the battery’s sticker can be scanned.

The screenshots below show the registration of a battery in a BMW program (left) and VCDS (right).

Diagnosis of the Intelligent Battery Sensor:

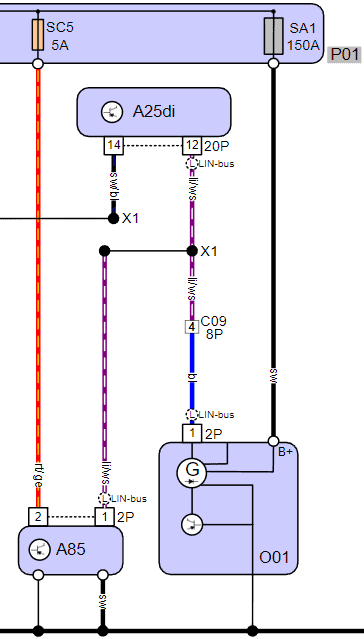

The intelligent battery sensor communicates with the alternator and the BCM or engine control unit. This section explains how to read the diagram and how to diagnose.

In the following diagram, we see the battery sensor (A85), which is powered by a 12-volt supply on pin 2 through a fuse. Pin 1 is for communication: from here, a message is sent via the LIN bus to the gateway (A25di) and the alternator (O01). Pins 1 and 2 are located in the two-pin connector shown in earlier images.

The lower two black wires on the battery sensor have no pin number: this is a direct connection to the negative terminal of the battery.

The intelligent battery sensor sends a LIN bus message to the gateway and the alternator. The gateway is the node between networks with different protocols (voltages and speeds). The LIN bus message is sent to the BCM and/or engine control unit via CAN bus in the gateway. Conversely, one of these two control units controls the alternator via the gateway and LIN bus.

A fault in the LIN bus communication can cause the battery sensor data not to be used, or the alternator not to be properly controlled. In the latter case, the alternator switches to an emergency program where the conventional D+ regulation is used to still generate sufficient charging voltage and current.

The voltage variation of the LIN bus signal can be measured with an oscilloscope to determine if there is a fault in the LIN signal.

Legend:

P01: fuse box engine compartment

A25di: diagnostic interface (gateway)

A85: ECU battery sensor

O01: alternator

When a fault is present and the LIN bus communication is in order, we know that the power supply and ground of the sensor are fine. The fault is caused by one of the components in this diagram. The following steps can be taken:

- check for software updates of the control units;

- test 12-volt battery (preferably under load);

- check if the correct battery data is registered. Perhaps the battery was replaced in the past, but the registration was never performed;

- reset the battery sensor data;

- check if the part number of the alternator is correct: a wrong alternator that doesn’t match the sensor will eventually cause problems;

- if the above has been checked and found to be in order, one might conclude that the battery sensor is defective. This sometimes occurs with frequent (improper) starting via jumper cables or a battery booster.

Related pages: