Introduction:

In vehicles with an internal combustion engine, the heat for interior heating is extracted from the cooling system. The low efficiency of the internal combustion engine (both gasoline, diesel, and LPG) is mainly due to heat losses. In the heater core, coolant circulates at a temperature of up to 90 degrees Celsius. The interior fan blows air through the heater core, warming up the air that enters the interior. To warm up the interior more quickly in winter, vehicles with internal combustion engines can also be equipped with auxiliary heating systems, in the form of electric heating resistors or a parking heater.

In electric vehicles, the heating source (the internal combustion engine) is absent. Therefore, the heat air produced by the heater must be generated in another way. This can be done in two ways:

- via electric heating resistors (PTC heating);

- by means of a heat pump (possibly in combination with PTC heating during startup).

Since heating resistors require a lot of power and can use up to 10% capacity of a fully charged HV battery, the heat pump is becoming increasingly popular. The heat pump is simply much more efficient. The heat pump utilizes the same components of the air conditioning system, but with the addition of extra components, the heat pump works as a “reverse” air conditioner. Knowledge of the operation of the conventional air conditioning system is therefore required before studying the operation of the heat pump.

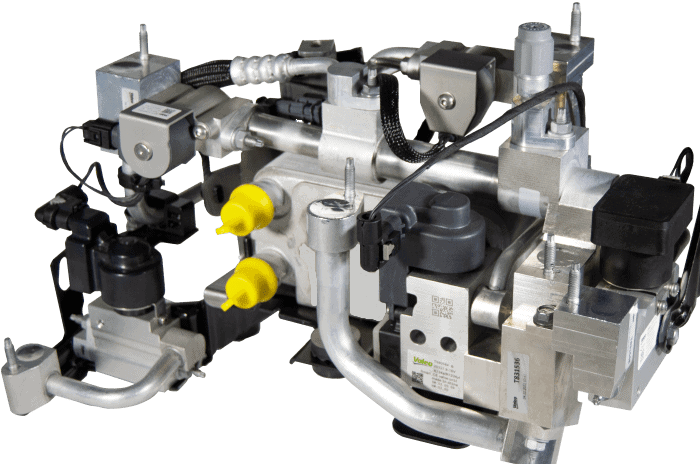

Video of the heat pump setup: Valeo heat pump

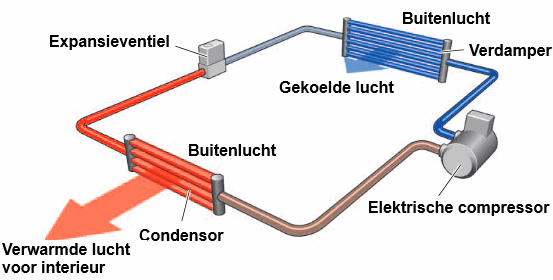

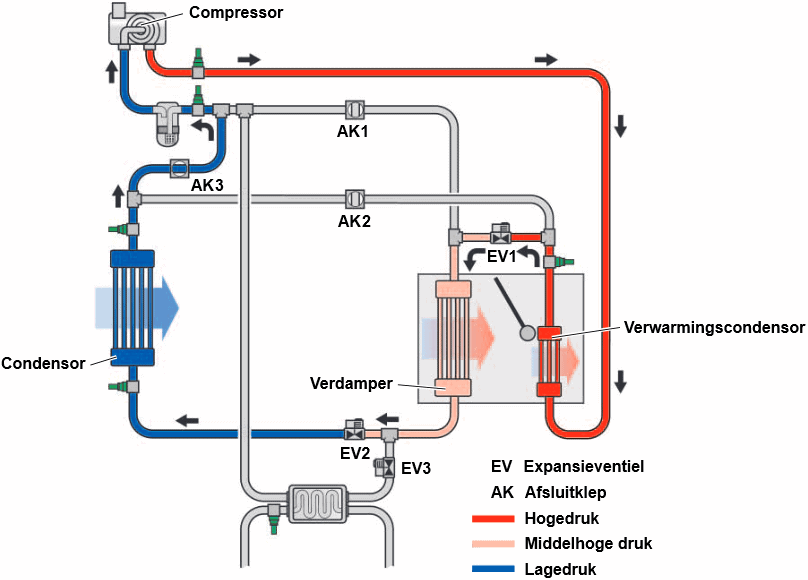

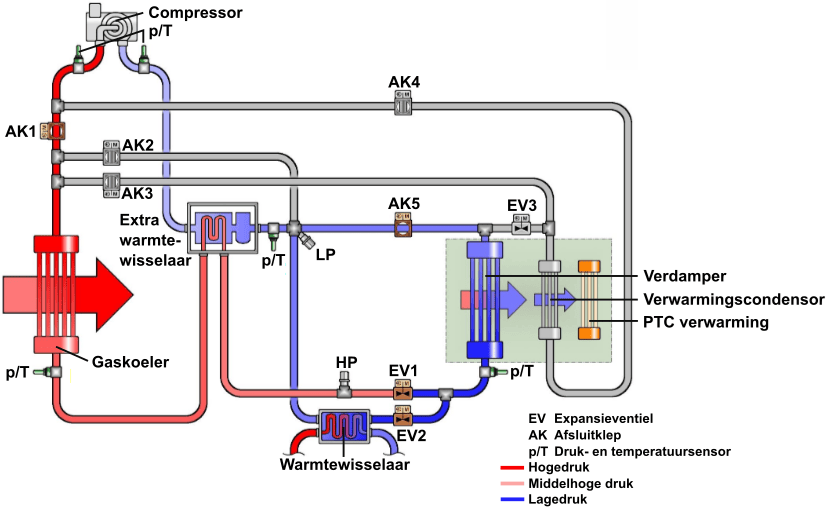

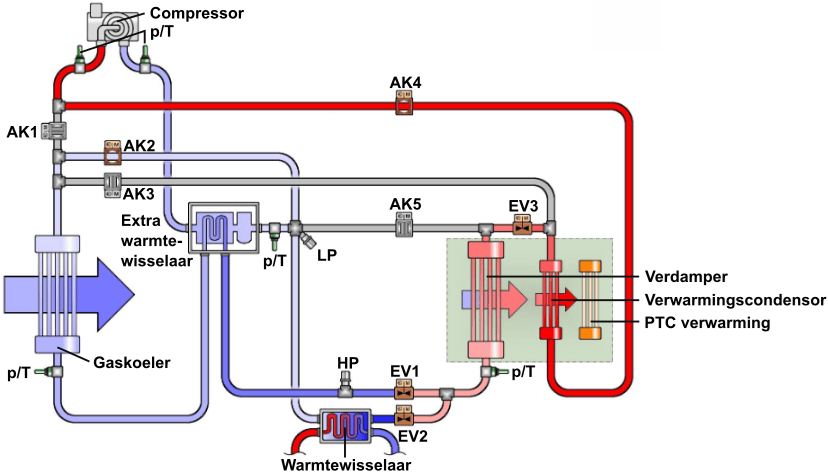

The following image shows the cycle of the heat pump. A heat pump essentially consists of the following main components: a compressor, evaporator, expansion valve, and condenser.

The compressor moves the gaseous refrigerant under increased pressure to the condenser. As a result of compression, the temperature of the refrigerant has increased. The refrigerant releases the heat to the air and condenses. The heated air flows into the interior. The refrigerant changes from a gaseous to a liquid state.

When the refrigerant flows through the expansion valve, another change of state occurs: here it goes from liquid to gaseous. In the evaporator, the refrigerant completely evaporates. The necessary evaporation heat is drawn from the warmer outside air, which is thereby cooled.

The gaseous refrigerant then flows from the evaporator back to the compressor.

As the above explanation shows, the heat pump uses the same components as the air conditioner, with the condenser and evaporator swapping tasks. The condenser is under the dashboard and the evaporator in the front near the radiator. The expansion valve also has a different location in the system, namely in the front of the vehicle near the evaporator. The heat pump can both heat and cool: for this, the components are used as we are accustomed to in air conditioning. Using switching valves, the condenser and evaporator exchange functions, and the expansion valve once again allows the refrigerant to evaporate in the evaporator under the dashboard.

The heat pump thus has both a heating and cooling function. This is not only useful for the interior but also for cooling and heating the HV battery pack, among others.

Heat pump with R134a or R1234yf:

As briefly described in the introduction, the heat pump can heat and cool both the interior and the components of the HV system.

In vehicles, we find heat pumps with two different types of refrigerants: the familiar R134a and R1234yf, or R744 (CO 2). The latter is discussed in the following section.

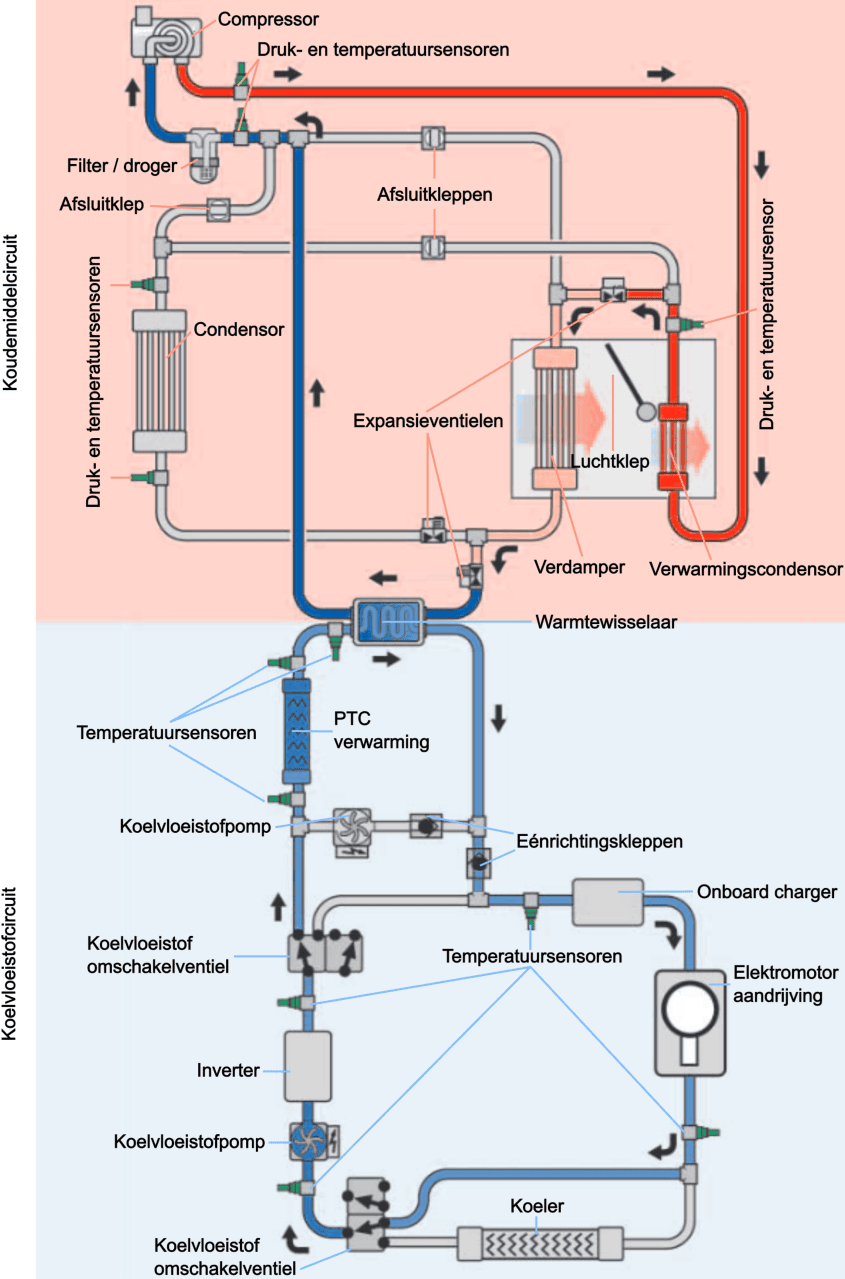

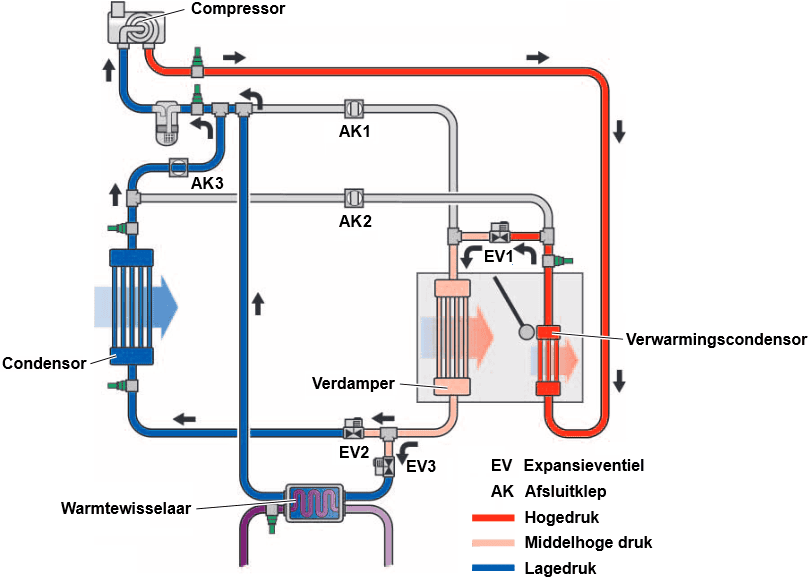

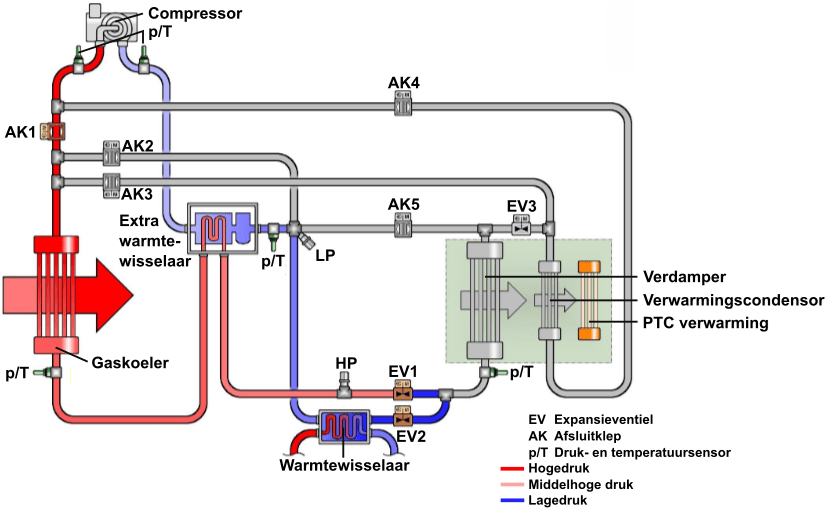

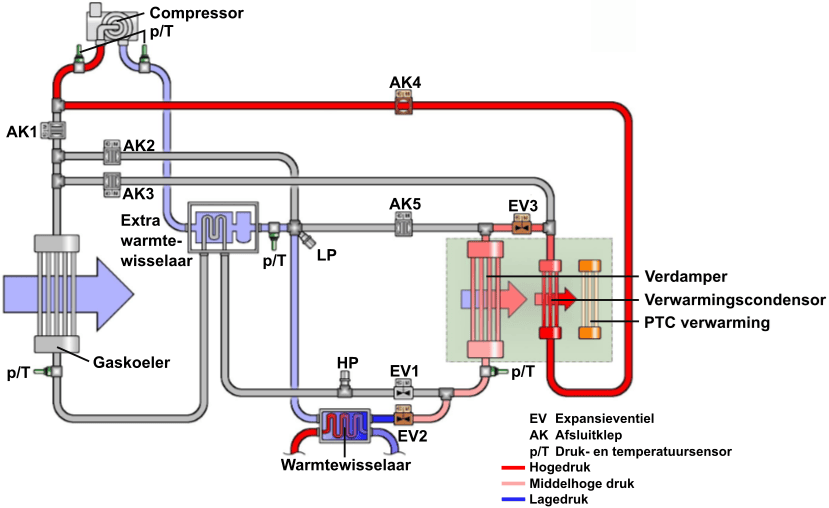

In the following image, two circuits are shown: at the top, the red refrigerant circuit and at the bottom, the blue coolant circuit. Both circuits are separate, but temperature transfer is possible via a heat exchanger.

The upper circuit focuses on the refrigerant cycle. The three shut-off valves steer the refrigerant in the correct direction. Additionally, there are three expansion valves that are activated depending on the position of the shut-off valves.

The components are named as in an air conditioning system: the condenser is at the front near the radiator, and the evaporator in the heater box under the dashboard. There is also a heating condenser, through which airflow can be directed or blocked using an air flap. The heating condenser is used for heating with the heat pump, while the evaporator plays a role in cooling with the air conditioning. Pressure and temperature sensors at multiple locations measure pressures and temperatures when the refrigerant changes direction via the shut-off valves.

The red lines in the refrigerant circuit indicate high pressure, the blue low pressure. The orange line and evaporator have a medium pressure, as there is an expansion valve on both sides. Arrows indicate the flow direction of the refrigerant.

The lower part shows the cooling system of the HV system. The heat exchanger transfers the temperature of the warm coolant to the refrigerant. The cooled HV components include the onboard charger (where AC is converted into DC during charging of the battery pack), the electric drive motor, and the inverter (where the DC from the battery pack is converted into sinusoidal AC for the electric motor).

The coolant switching valves determine the flow direction of the coolant. Arrows indicate how the flow proceeds in the switched state. The coolant can be routed through the cooler to cool or via the PTC heating to heat.

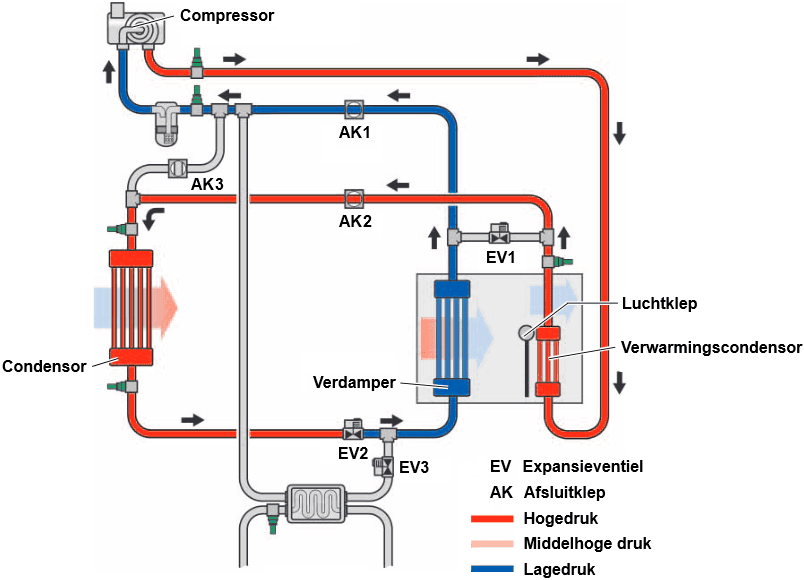

As already described above, the heat pump can function as air conditioning or heating. The three situations below show the direction of the refrigerant through the components to allow the heat pump to function as air conditioning, interior heating, or interior heating and HV package cooling

1. Air Conditioning

The (AC) compressor draws the gaseous refrigerant through the low-pressure line (blue) and compresses it through the high-pressure line (red) to the heating condenser in the heater box. The air flap is closed, preventing any airflow through the heating condenser and consequently no heat is released. Thus, no condensation occurs.

The refrigerant flows through to the condenser via SV2 (shut-off valve 2). In the condenser, the refrigerant condenses and becomes liquid.

After the condenser, the refrigerant reaches EV2 (expansion valve 2). Here it undergoes a pressure drop, causing the refrigerant to evaporate and releasing heat to the evaporator. This heat is absorbed by the interior air, which is then blown into the interior.

From the evaporator, the gaseous refrigerant flows back to the suction side of the compressor via SV1 (shut-off valve 1).

Shut-off valve 3 is closed, preventing the refrigerant from using this line. Expansion valves EV1 and EV3 are also closed, blocking passage. All expansion valves can work in two directions. During heating functions, the shut-off valves direct the refrigerant in a different direction, while the expansion valves ensure pressure reduction in the opposite direction.

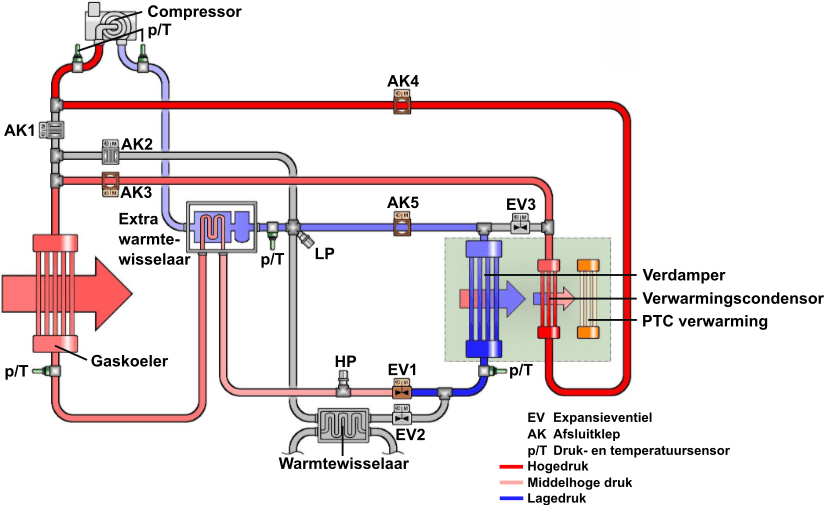

2. Interior Heating

The compressor compresses the refrigerant, which is then transported as gaseous refrigerant through the high-pressure line to the heating condenser.

The temperature of the heating condenser rises, causing the interior air, previously preheated in the evaporator, to absorb the heat released during the condensation of the refrigerant in the heating condenser.

Shut-off valves SV1 and SV2 are closed, so the refrigerant after the heating condenser undergoes a pressure drop in EV1 (expansion valve). This partially vaporizes the refrigerant. In the evaporator, functioning as a condenser in this situation, the refrigerant condenses again, releasing heat to the incoming interior air. The refrigerant again undergoes a pressure drop in EV2, causing its temperature to drop below the ambient temperature. In the condenser, acting as the evaporator in this situation, the refrigerant evaporates and absorbs heat from the outside air, which has a higher temperature. The gaseous refrigerant flows back to the compressor via SV3.

In traditional air conditioning systems, the condenser is located at the front of the vehicle, where the driving wind (or airflow from the fan) absorbs the heat of the refrigerant and lowers the temperature of the refrigerant. However, in a heat pump, this heat is not released to the driving wind but used for heating the incoming interior air. The condenser and evaporator have thus swapped functions.

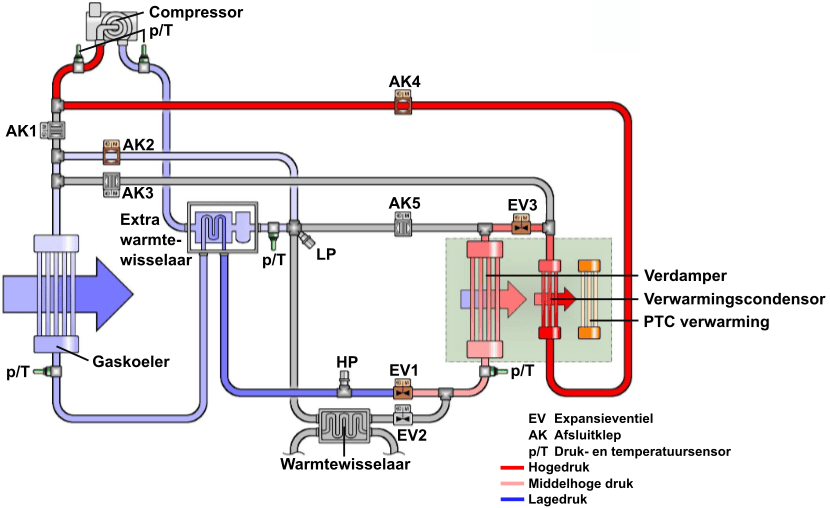

3. Interior Heating and HV Components Cooling

In the heat pump system, the refrigerant needs to expand for the transition from liquid to gas. There are expansion valves in front of the condenser (functioning as evaporator) and the heat exchanger responsible for the heat transfer between refrigerant and the coolant circuit of the HV components.

EV2 and EV3 are open in this situation. It is also possible that only EV3 is open. In that case, the heat from the cooling system of the HV components is used for the expansion. After expanding, the refrigerant’s temperature is lower than the ambient temperature. This cooling draws heat in the heat exchanger from the electric drivetrain’s cooling circuit, helping to cool the HV components: the coolant transports the heat from, among others, the inverter, and the electric motor is dissipated via the heat exchanger to the refrigerant.

If both the condenser and the heat exchanger fail to generate enough heat to condense the refrigerant, for example, if the vehicle remains stationary for an extended period with heating on, the PTC heating element is activated in the cooling system to raise the coolant temperature in the heat exchanger. The shielded cooling circuit with its own coolant pump prevents sensitive parts like power electronics, the onboard charger, and the electric motor from being unintentionally heated, as the heating is solely intended to allow the refrigerant to expand. This situation will not occur if the inverter and electric motor need to deliver high power, as this generates sufficient heat that may even need to be limited via the cooler.

Heat Pump with R744 (CO0A2):

The refrigerant R744 (CO0A2) is increasingly used in air conditioning and heat pump systems, such as in electric vehicles. CO0A2 has the property of absorbing a lot of heat during evaporation and releasing a lot of heat during condensation. This makes it very effective for heat transfer. However, a significant limitation of CO0A2 is the critical temperature of 31 0C. Above this temperature, CO0A2 cannot condense, making it difficult to function efficiently during hot summer temperatures. To remedy this, an additional internal heat exchanger is added in vehicles, which uses low-pressure refrigerant between the evaporator and compressor to condense the warm, high-pressure refrigerant in the gas cooler.

Compared to other refrigerants, such as R1234yf, CO0A2 operates at much higher pressures. The standstill pressure at 20 0A0C is 57 bars, and during operation, the pressure on the low-pressure side can rise to 90 bars, with a pressure relief valve opening at 160 bars. This requires more robust systems, such as a compressor with thicker walls and flexible hoses with a corrugated steel lining for protection against high pressure and thermal stress.

A key advantage of CO0A2 as a refrigerant is that it can still heat effectively at extremely low outside temperatures, such as below -10 0A0C. Unlike R1234yf, which boils at -29 0A0C, CO0A2 remains gaseous at temperatures below -79 0A0C, allowing it to function in very cold environments. This makes CO0A2 particularly suitable for use in vehicles as both a cooling and heating system, with better performance at low temperatures than traditional refrigerants.

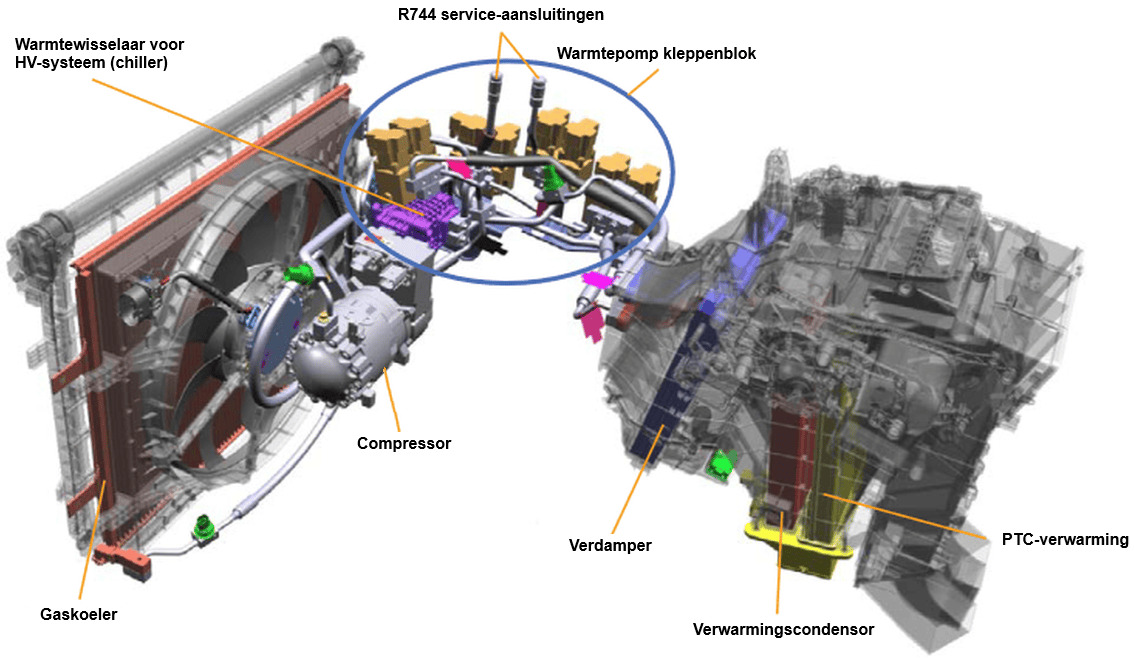

The above image shows the components of the R744 heat pump system (drawing: VAG). Below, seven possibilities are shown how the heat pump can provide cooling and heating for the entire system or portions of the system.

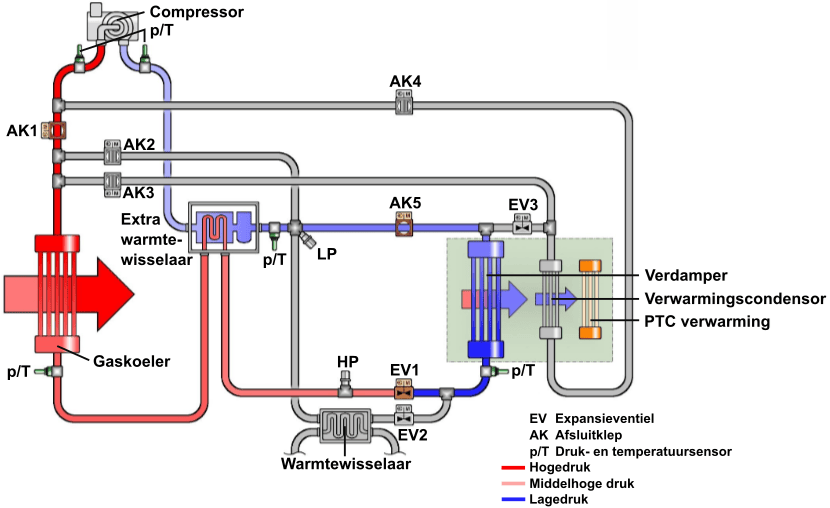

1. Interior Cooling:

The refrigerant flows through the compressor to the gas cooler in the front of the car, where it condenses and releases heat to the outside air. The refrigerant experiences a pressure drop via expansion valve (EV1), then absorbs the warm air from the interior in the evaporator, causing the temperature of the air flowing to the interior to drop. The additional heat exchanger between the gas cooler and the expansion valve ensures further cooling of the refrigerant to allow complete condensation. At higher outside temperatures, the gas cooler may not work sufficiently to fully condense the refrigerant, as the critical temperature of CO0A2 is 31 0A0C.

2. Interior and HV Battery Pack Cooling:

Just like in situation 1 where only the interior was cooled, in this situation the compressor moves the refrigerant to the gas cooler in the front of the car. Now EV2 (expansion valve 2 for the heat exchanger) is also open. The two expansion valves (EV1 and EV2) cause the refrigerant to expand both to cool the interior air and the HV battery pack via the heat exchanger (chiller). The battery pack is actively cooled in this way once the temperature exceeds 30 to 35 0A0C.

3. HV Battery Pack Cooling:

The HV battery pack can be cooled without cooling the interior. When the HV battery temperature exceeds 30 to 35 0A0C, the refrigerant is directed from the gas cooler through EV1 and EV2 via the heat exchanger (chiller), absorbing heat from the battery and keeping the temperature under control. This cooling is essential for the battery’s lifespan. To prevent the refrigerant from flowing through the evaporator, shut-off valves SV3, SV4, SV5 are closed.

4. Reheat Phase:

In the reheat phase, the cooled air coming from the evaporator is reheated using the heating condenser.

The reheat function is used in low outside temperatures, for example, when the windshield needs defrosting while humidity is high. The dry, cold air from the evaporator is heated so that the interior is simultaneously heated and dehumidified.

5. Air Heat Pump:

Just like the R134a heat pump, the gaseous refrigerant flows from the compressor through the heating condenser and the evaporator, where the heat from the refrigerant is released to the incoming interior air.

Yet, at the startup of the CO0A2 heat pump, it takes some time for the heating condenser to reach sufficient temperature to bring the interior air to the desired temperature, as heat cannot yet be extracted from the HV circuit.

To immediately get heat into the interior after starting the car, the PTC heater is activated.

6. Air-Water Heat Pump:

Just like in situation 6, the heat pump can absorb heat from the outside air, but in this situation, it also absorbs heat from the cooling system of the HV battery pack.

Via the compressor and the open shut-off valve SV4, the refrigerant is directed to the heating condenser and the evaporator, where it releases heat to the incoming interior air. Simultaneously, the refrigerant flows through EV1 into the gas cooler at the front of the car, where it absorbs heat from the outside air, and through EV2, where it absorbs heat from the cooling system of the HV system.

7. Water Heat Pump:

The CO0A2 heat pump can also function as a water heat pump at low outside temperatures, extracting heat from the HV cooling system and transferring it to the interior or other vehicle systems.

Via the compressor, the refrigerant is transferred under high pressure to the heating condenser and the evaporator to warm the incoming air. The refrigerant then expands via expansion valve 2 in the heat exchanger (chiller), to then be drawn through the additional heat exchanger by the compressor.

Related pages: