Introduction:

Glow plugs are also known as glow sticks. Both names are correct, but on this page, only the term glow plug will be used. Every diesel engine has glow plugs. An indirectly injected diesel engine always needs glow plugs for a cold start. A directly injected diesel engine can start without glow plugs at outside temperatures above 10 °C, but it emits significantly more pollutants, including soot. Additionally, a diesel engine with a malfunctioning glow system will also have difficulty regenerating the diesel particulate filter due to the insufficient temperature.

Because of the large heat-dissipating surface of a combustion chamber or swirl chamber in an indirectly injected diesel engine, it is essential to warm the air in the combustion chamber during a cold start. This is done using glow plugs.a0

Function of the Glow Plug:

When the ignition is turned on, a high current immediately flows through the cold glow plug. This current ensures that the glow plug reaches a very high temperature within a few seconds. The current decreases as the engine temperature rises. This is because the resistance of the control coil increases with the temperature. Thus, a metal glow plug maintains a consistent temperature of around 1000 degrees Celsius, while a ceramic glow plug maintains about 1400 °C.a0

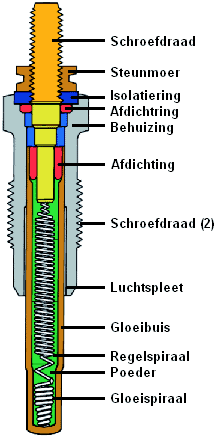

A glow plug consists of a heating coil and a control coil, housed in a glow tube. The heating coil makes the end of the glow tube glow. The heating coil and control coil are firmly embedded in a powder that is electrically insulating but conducts heat well.

In modern cars, the system begins preheating as soon as the car is unlocked or the driver’s door is opened. At that moment, the engine control unit receives a signal that the engine will be started ‘soon.’ By activating the glow plugs early, the air in the combustion chamber and the engine materials are already somewhat heated before the engine starts.

The glow plug reaches its operating temperature in about five seconds. The heating time is electronically controlled. Usually, the glow plugs remain active even after the engine has started, depending on the ambient temperature. Post-heating ensures the engine runs smoothly immediately after a cold start and reduces soot emissions.

The glow plugs are also activated during the regeneration process of the diesel particulate filter.

The images below show a direct (left) and indirect (right) injected diesel engine. In the direct injected diesel engine, the glow plug is located directly next to the injector above the piston. In the indirect injected version, the glow plug is mounted in the prechamber.

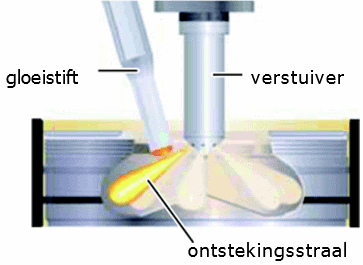

Some engines use an ignition spray. In this setup, a spray of fuel from one of the injector holes is directed at the glow plug. The fuel comes into contact with the hot glow plug, causing it to evaporate more quickly. A combustible mixture forms more rapidly, allowing the engine to run better during a cold start. The illustration shows the ignition spray in a direct-injected diesel engine.

Computer-controlled Glow Plugs:

In electronically controlled glow plugs, the control coil described in the previous section is omitted. The temperature is then indirectly controlled by the engine management computer rather than the control coil. This ECU determines the preheating time, glow duration, and control.

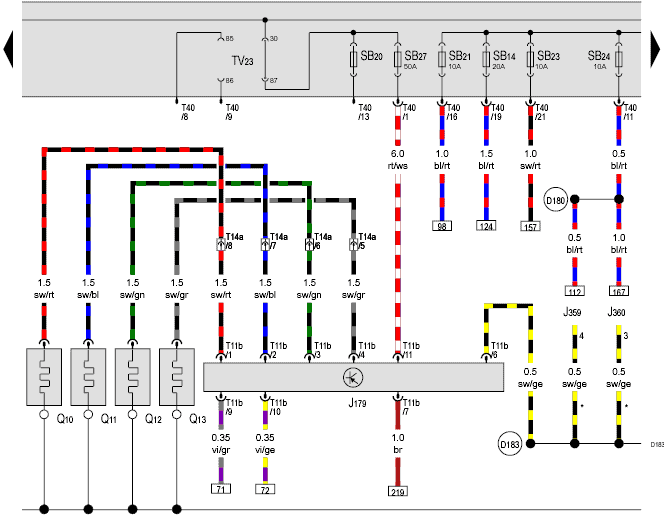

The diagram shows the components of the glow system of a VW Golf VI 2.0 tdi engine:

- J179: glow automaton (control unit)

- Q10 to Q13: glow plugs cylinders 1 to 4.

The glow plugs are powered by the preheating automaton (J179), also known as the glow control unit or glow relay. Pin 11 and 7 of the glow automaton are connected to the fuse box (plus) and a ground point on the chassis.

The glow automaton is connected to the engine control unit via vi/gr and vi/ge wires (at positions T11b pins 9 and 10). This ECU can be referenced with numbers 71 and 72 on another diagram.a0

The signal transmission or communication between the glow automaton and the engine ECU can be established via LIN-bus in other engine types. The glow automaton communicates with the engine ECU on when and how long the glow plugs should be activated, and provides feedback if a glow plug is faulty, allowing the engine ECU to store an error.

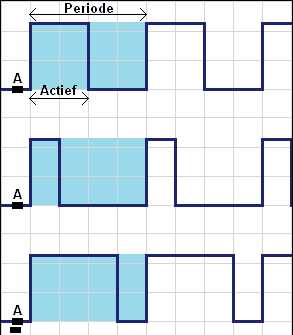

The glow automaton controls the glow plugs using a Pulse Width Modulation (PWM) signal.a0The pulse width determines the control and, thus, the temperature of the glow plugs. The wider the “active” section in one period of the PWM signal, the hotter the glow plug will be. The illustration shows the principle of a PWM signal:

- top: duty cycle of 50%;

- middle: duty cycle of 25% (a quarter of the period time active)

- bottom: 75% (three-quarters of the period time active). The average voltage is therefore the highest of the three PWM signals shown.

In the first phase of the preheating process, the glow plugs are controlled with a duty cycle > 95%, which translates to an average voltage of around 13 volts. This means the glow plugs quickly reach a temperature of approximately 1100 °C. The voltage is then lowered incrementally to an average of 4 volts. The temperature drops to about 1000 °C and is then maintained. Post-heating stops:

- after the glow plugs have been activated for a certain period;

- if the coolant temperature exceeds approximately 60 °C

Glow Plug Control When Starting the Engine:

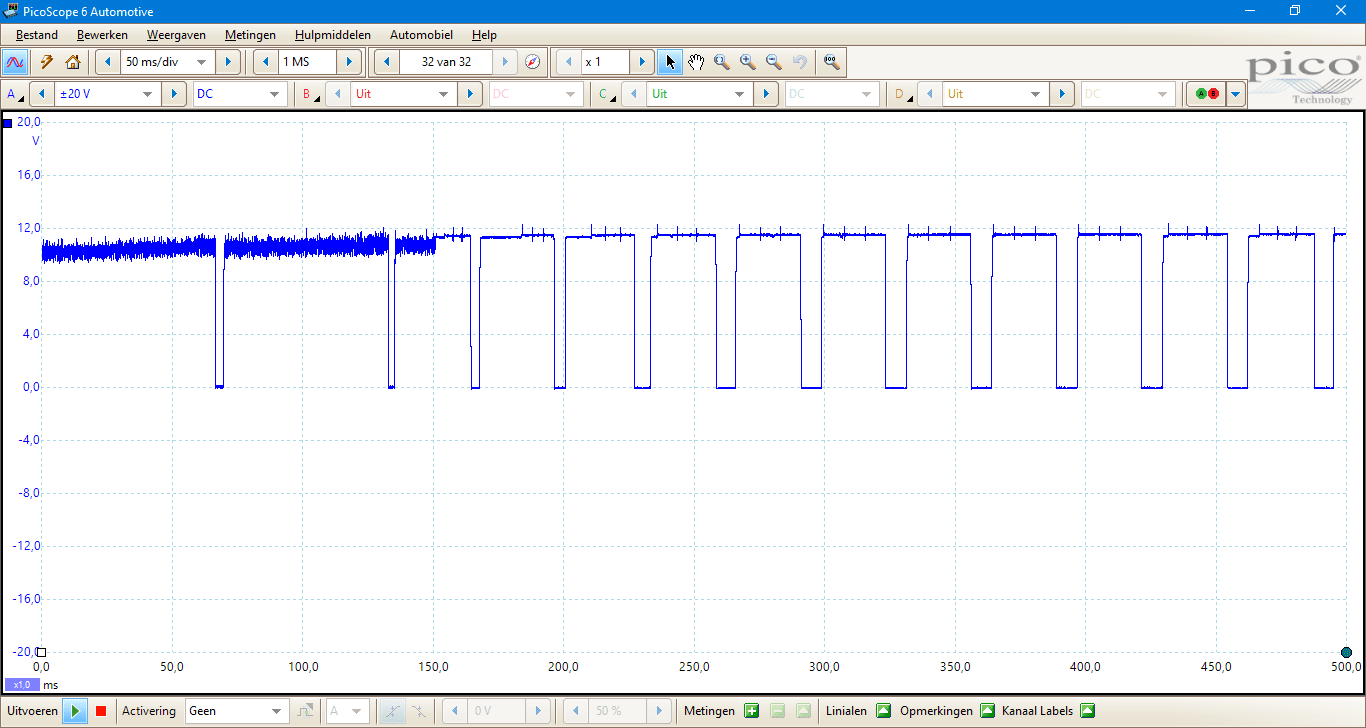

When the engine is started, the glow controller powers the glow plugs for a specific time with a constant voltage of 12 volts. This is also known as the “preglow,” translated from Dutch as “voorgloei.” This control method ensures that the glow plug reaches its operating temperature as quickly as possible. If the coolant temperature is below 25°C, this preheating time is needed. The lower the temperature, the longer the preglow will last.

- if the coolant temperature is above 25°C, no preglow occurs;

- at a temperature of 25°C, the preglow lasts 0.5 seconds;

- at a temperature below -25°C, the preglow lasts between 2.5 and 3 seconds.

The oscilloscope images were recorded on a glow system with ceramic glow plugs (BMW 320d, N47, 2011). These reach temperature faster than metal glow plugs. The preglow may last longer. After some time, the glow plug reaches its operating temperature and is controlled in a pulsing manner to maintain that temperature. In this oscilloscope image, you can see that the on time (12 volts) becomes shorter over time.

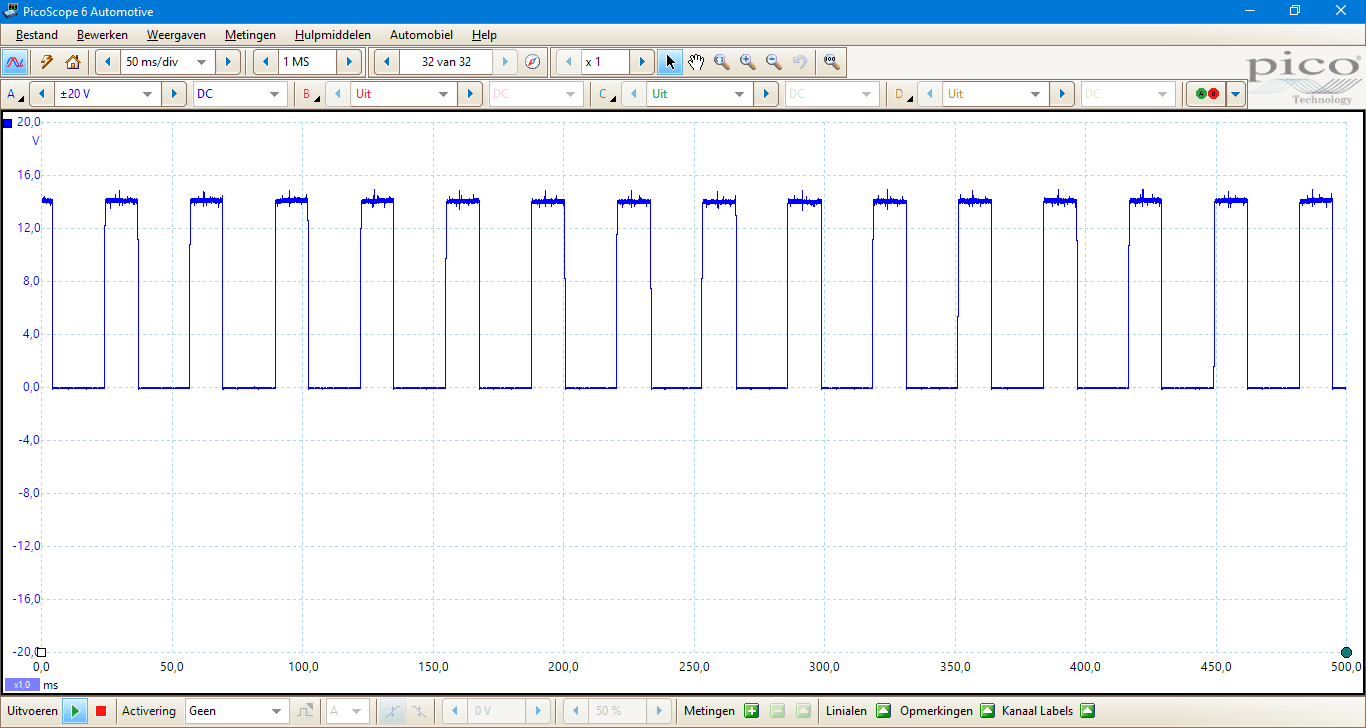

Post-heating After the Engine Starts:

A few seconds after the engine has started, the glow control unit continues to pulsate the glow plugs. This keeps the glow plugs at temperature to post-heat. This helps minimize diesel knock and harmful emissions. Post-heating remains until the coolant reaches a minimum temperature of 60°C (the actual cut-off temperature may vary by brand or model). The duty cycle remains constant in the post-heating phase.

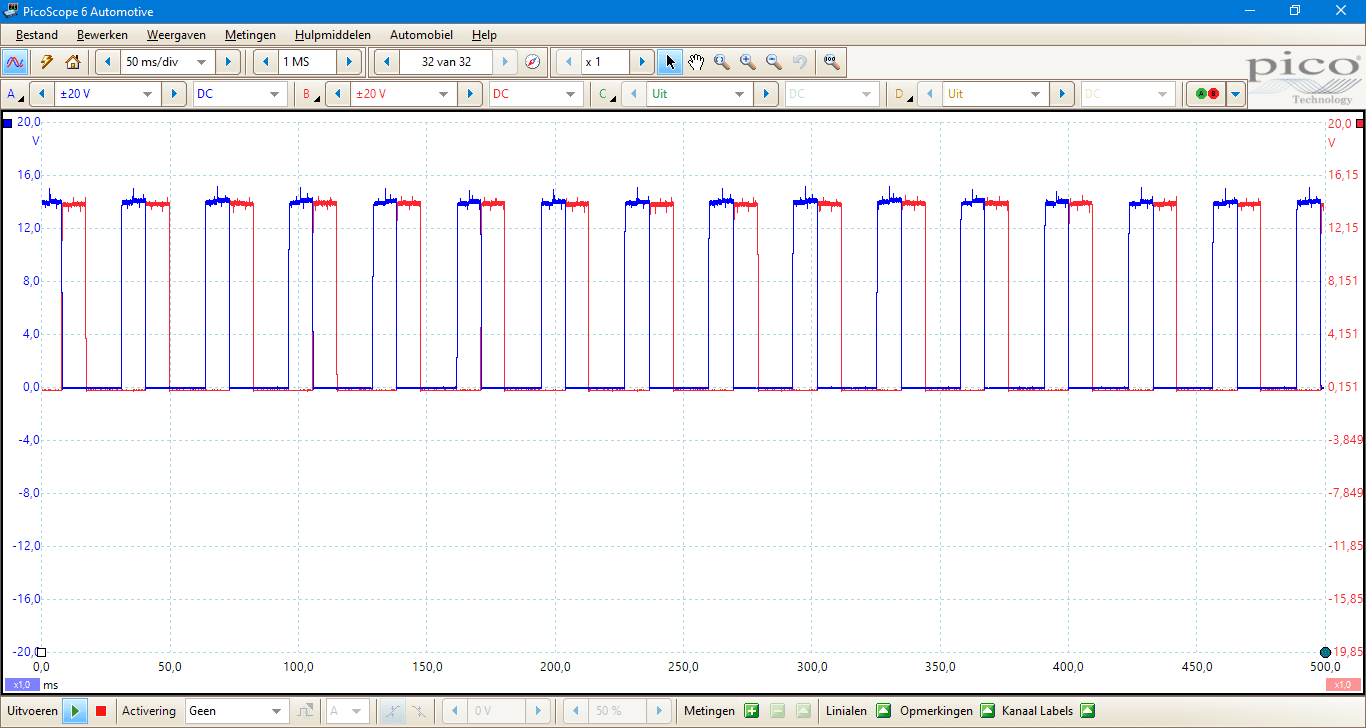

Glow Plug Control of Multiple Glow Plugs:

The glow control unit activates the glow plugs one by one. With wider pulses, the pulses partially overlap. The reason for controlling the glow plugs individually is as follows:

- if all the glow plugs of the engine receive a pulse simultaneously, they will also collectively carry a current. In that case, there is briefly a lot of current (when pulses for four glow plugs are combined), and when the voltage is 0 volts, no current would flow. This switching on and off of a large current would place an unnecessary high load on the power supply system;

- by alternating the pulses between cylinders, the current through the glow controller is kept constant but distributed across the glow plugs.

The following oscilloscope image shows the control pulses of two glow plugs. In this case, for cylinders 1 and 2. All four glow plugs can be controlled individually or in groups (e.g., cylinders 1 and 4 together, and 2 and 3 together).

Glow Plug Failures:

When glow plugs are defective, symptoms may include engine speed fluctuations or diesel knock after the engine has started from a cold start. There can be significant soot development (not noticeable if a diesel particulate filter is installed). Additionally, a consequence of one or more defective glow plugs may prevent the particulate filter from regenerating. The necessary temperature is not achieved, causing saturation with too many soot particles. Modern systems detect faulty glow plugs through the engine management system. The glow control unit always performs a resistance measurement (via a voltage drop across a shunt) and communicates the status of the glow plugs (often via LIN-bus) with the engine control unit. Error messages on the dashboard often appear only at low outside air temperatures. At temperatures above 5°C to 10°C, a fault is stored, retrievable with an OBD system, but no dash indication alerts the driver.

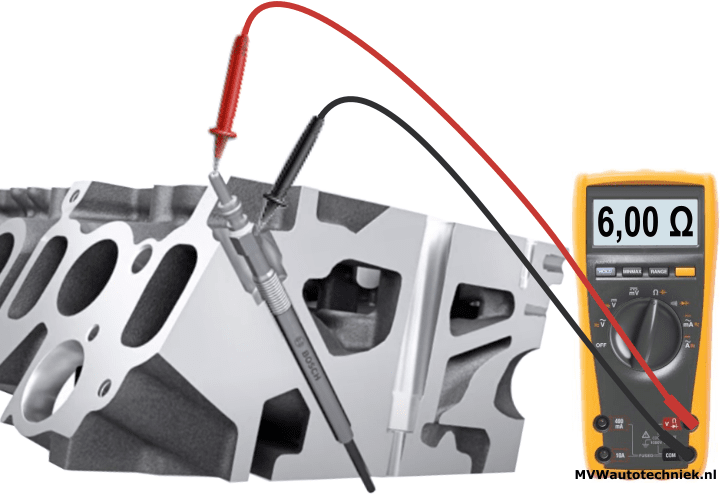

If a glow plug is suspected to be defective, a resistance measurement can be performed using a multimeter. The measurement can be conducted while the glow plug is in the engine block or on a removed glow plug. Given the risk of breaking when removing glow plugs, it’s advisable initially to measure them in the installed state.

- detach the connector from the glow plug and set it aside;

- place the red probe on the top of the glow plug where the connector should be connected;

- place the black probe (preferably) on the housing of the glow plug, elsewhere on the engine block, or at a suitable ground point;

- set the multimeter to the “ohm” setting to measure resistance.

The resistance value does not indicate how well a glow plug works. You measure the resistance through the coil. The metal or ceramic tip may be dirty or glow less efficiently with age. However, the resistance measurement can determine if the glow plug can glow once current flows through the coil:

- a resistance between 0.2 and 6 Ω is good;

- a resistance <0.2 Ω is too low. The coil (plus) and housing (ground) likely make internal contact;

- no resistance (OL or 1.) means an internal break in the glow plug. No current can flow through it;

- a very high resistance (e.g., 6 kΩ) also indicates a defect. This results in low current flow, and the glow plug barely heats up.

If one or more glow plugs have incorrect resistance values but all four are the same age, the manufacturer advises replacing all glow plugs simultaneously. Even if resistance measurements are satisfactory, aging may have reduced glowing properties. With four new glow plugs, one is assured that there are no variations in glowing properties and temperature.

Glow plugs controlled by a glow automaton with a pulse can be identified by their housing voltage: 5.3 or 7 volts. This is the operational voltage needed for maintaining temperature. Whereas glow plugs from older engines could be tested with a 12-volt battery, newer types can overheat and become defective if supplied with 12 volts for too long.

Removing Glow Plugs:

When removing a glow plug, take care to unscrew it with minimal force. Excessive force may damage the threads or cylinder head, or cause the glow plug to break. To avoid this, it’s recommended to bring the engine to operating temperature first. Warming the materials of the glow plug and cylinder head softens any caked carbon residue. The glow plug can then be more easily removed than with a cold engine.

If the glow plug breaks, it’s often necessary to drill a hole in the glow plug and then remove the threads and remaining head from the hole or cylinder, possibly using a magnet. There is a risk that the threads may be damaged during drilling if not done carefully. There is specialized equipment to drill at the correct angle (see the image below). In the worst-case scenario, the cylinder head must be removed to extract the glow plugs. Leave glow plug replacement to a specialist.

The most common cause of a glow plug breaking is over-tightening in the past. Glow plugs have a tightening torque of between 10 and 25 Nm, depending on the thread. Always consult the workshop manual or the specifications of the specific glow plug for the correct tightening torque.

Related pages: