History:

The G-lader was invented in 1905 by the Frenchman Le Creux. When Volkswagen decided to achieve power through superchargers, they further developed the concept by Le Creux. About 400 different versions were developed before VW produced the older generations of the G-lader (Golf / Corrado / Polo G40 and G60).

Operation:

The G-lader is a mechanical compressor driven via the crankshaft. The advantage is that the compressor works as soon as the accelerator pedal is pressed; unlike the turbo, which must first be driven by exhaust gases. Therefore, the G-lader has a very fast response time. This gives the driver the feeling of driving with an engine of much larger displacement.

A G-lader is essentially a dual spiral chamber (snail shell) inside. The incoming air arriving in the left outer spiral chamber of the G-lader is displaced by an eccentric motion through the right outer spiral chamber and discharged to the intercooler at a standard pressure of 0.7 bar. The air temperature can rise to 100 degrees Celsius due to compression. The intercooler then cools it down to about 65 degrees. The cooled air is then pressed into the intake manifold.

The operation of compressing the air is illustrated by the animation.

A G-lader should be overhauled approximately every 50,000 km. It was discontinued by Volkswagen due to its vulnerability (dust particles in the intake air), maintenance sensitivity, and high repair costs. A Roots-type supercharger is a better alternative, which is still regularly used by car manufacturers today.

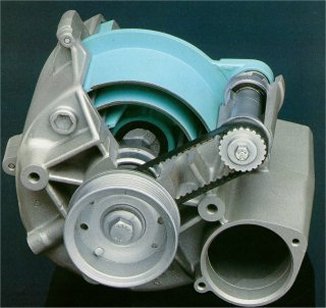

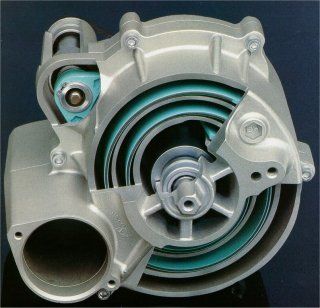

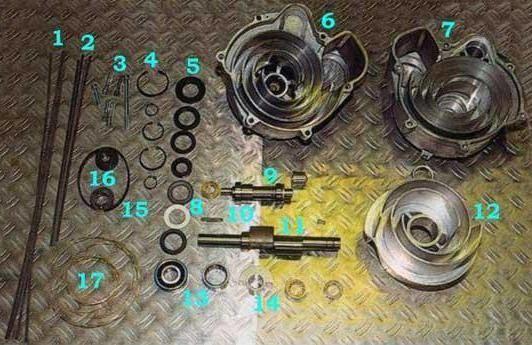

The image below shows all the parts of a dismantled G-lader. Below it are two images of a refurbished G-lader.

1: Long sealing strips.

2: Short sealing strips.

3: Bolts from the housings.

4: Retaining rings

5: Seals (oil channel sealing).

6: Exhaust housing

7: Intake housing

8: Seals

9: Balancing shaft

10: Dowel pin

11: Main shaft

12: Displacer

13: Bearings of the main shaft

14: Counterweight

15: Toothed belt

16: Gears of main shaft and balancing shaft

17: Spring strips